Not every hammer will fit every excavator - and it's not just a question of fitting. The wrong fit can put strain on the hydraulic system, shorten the life of the arm and, in extreme cases, lead to costly failures. So if you're wondering how to choose a hydraulic breaker for excavators or crawler excavators, you've come to the right place. Below you'll find specific, technically sound guidance to help you choose the equipment that suits your needs and your carrier - without compromise.

Whether you're looking for a lightweight hammer for everyday service work or a heavy-duty unit for demolition, we'll tell you what to look out for.

Before you choose a breaker - check the weight of your excavator with demolition breaker and its hydraulic system.

Before you enter the world of impact parameters, energy or hammer brand, stop for a moment at your machine. It is the excavator's weight and its hydraulic capabilities that will determine whether the hammer will operate smoothly, safely and efficiently. If you underestimate these figures, you could very quickly overload the system, wear out components faster... and incur avoidable costs.

The most important parameters you need to know are:

- excavator empty weight,

- oil flow (l/min),

- systemoperating pressure (bar).

For example: if your crawler excavator weighs around 10 tonnes and offers a flow rate of 80-100 l/min, it is worth looking at breakers that will not exceed an operating weight of around 650-700 kg and are compatible with this hydraulics. So the choice of hydraulic breakers for excavators doesn't end with the catalogue - you need to know your equipment well. The hydraulic breakers hammers for excavators category will help here, where each model includes full specifications.

Impact energy? Fine, but within reason

You will often come across the belief that the higher the impact energy, the better. And indeed - when it comes to demolition work or breaking large concrete blocks, this power gets the job done. But only if it is matched to the design of the carrier. Too much energy can cause too much vibration, which will damage the quick coupler, arm or undercarriage over time.

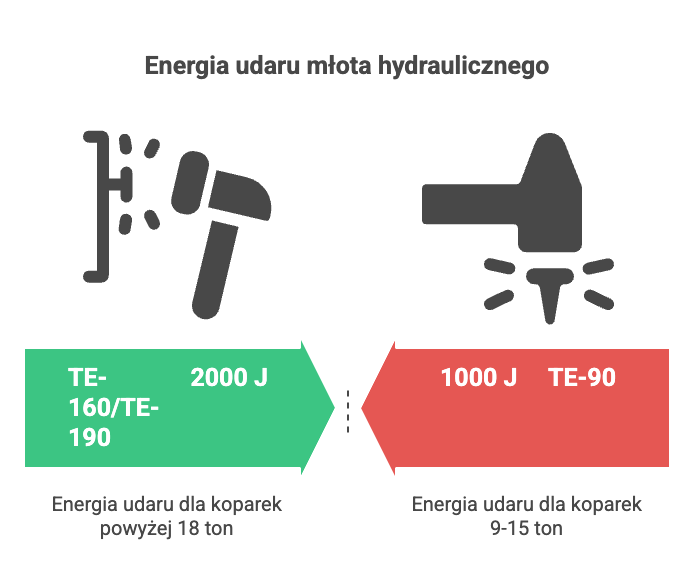

For excavators weighing 9-15 tonnes, look for hammers with an impact energy of 1 000 to 2 000 J. An example is the TE-90 model - dedicated to this class of machine. It offers high impact and stability while having the right weight distribution that does not destabilise the arm.

And if you're operating a larger machine - over 18 tonnes - you might consider the TE-160 or TE-190 series hydraulic breakers for excavators with demolition breakers for excavators, which offer even greater impact. You'll find them in the hydraulic breakers category for crawler excavators.

Match the hammer for excavators with demolition breaker to the nature of the job - not to the toughest task

Just because you occasionally find yourself demolishing an old foundation or pavement, doesn't mean you have to choose a breaker for that one, most demanding task. The choice of hydraulic breakers hammers for excavators should be a compromise - between strength, weight and range of applications.

If the majority of the work is paving services, demolition of single-family houses, dismantling concrete pavement- a model with medium impact energy, but with a precise chisel, good cushioning and lightweight construction will suffice.

The TE-90 demolition hammer from the TECHNA series is ideal for such applications. Its parameters are tailored for machines weighing up to 15 tonnes, and its BOX-type design provides better vibration dampening and less strain on the arm.

How to choose hydraulic breakers for excavators and crawler excavators? Don't forget lubrication, cooling and simplicity of design

Even the most powerful hammer for excavators won't last long without proper lubrication and a proper cooling system. The longer you work continuously - such as demolition - the more you need a model that is resistant to overheating and has easy access to service points.

Many operators appreciate designs without electronics - ones where you can quickly change bushings, guards and chisel without specialised tools. In this context, the TE-130 and TE-160 are a solid choice. They have mechanical vibration dampening, an efficient oil flow system and easily accessible maintenance points.

And if you're working with smaller equipment - check out hydraulic breakers for mini excavators, which are also designed for low failure rates.

Mounting, handle, chisel - not everything can be 'matched later'

Unfortunately, many users leave the subject of chucks and working tools to the very end. And this is a big mistake. If the hammer doesn't fit the quick coupler, you'll lose time making adapters or welding, and this always involves additional costs. When choosing hydraulic breakers for excavators with demolition breaker excavators, make sure you get a set with a chuck that fits your machine - or at least has a configuration option.

The chisel itself is no less important - ideally it should be hardened, with increased wear resistance and easy attachment and replacement. Models such as the TE-160 have a piston protection system, which reduces wear on the components and extends the life of the whole set-up.

We offer hammers for excavators with demolition breaker for CAT backhoe loaders, hydraulic breakers for JCB, Kubota hammers and Bobcat hammers for efficient and trouble-free operation in any terrain.

What to look for when choosing hydraulic breakers hammers for excavators? A practical checklist

Before you decide to buy hydraulic breakers hammers for excavators, it's worth looking at the subject holistically.

- The type of machine - mini excavator, crawler excavator, backhoe loader or loader? Each has different design and hydraulic requirements.

- Carrier weight - the lighter the machine, the smaller and lighter the breaker. For example:

- 1-3 t → hammer up to 200 kg,

- 4-6 t → 300-450 kg,

- 7-10 t → 500-800 kg,

- 11 t+ → even above 1000 kg.

- Impact energy and frequency of blows - the harder the material (rock, reinforced concrete), the higher the parameters the hammer should have.

- Type of work - demolition, asphalt demolition, underwater work? Choose a hammer suitable for your specific application.

- Hammer type - there are specialist models (for rock, asphalt, concrete) and universal models (e.g. TEHB70U, TEHB100U).

- Hydraulic performance of the machine - oil flow (l/min) and operating pressure must match the requirements of the hammer.

- Mounting type - check that the chuck and quick coupler match the arm of your machine.

- Service and parts availability - do you have easy access to replacements, grease, repair kits in case of breakdown?

- Technical support - a good dealer is not just a shop, but a partner who will advise, fit the hammer to the machine and help with installation.

- Warranty and documentation - the warranty card, instruction manual and DTR are absolute basics that should not be overlooked.

Choosing a hydraulic breaker for excavators is a decision that will affect your comfort and efficiency for years to come. Therefore, it is not worth making it hastily. Instead of being guided solely by price or a well-known brand name - start with your machine. Its weight, hydraulic capacity and scope of work are the best starting point.

If you are looking for tried-and-tested models and need specific help with your selection - take a look at our range of hammers for excavators with demolition breaker excavators or mini excavators.

At TechnaPoland, we will advise you on the ideal model for your scope of work and equipment. Without ambiguity. With guaranteed performance.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- How does a hydraulic breaker work?

- Hydraulic breakers for excavators with demolition breaker - what to look for when choosing one?

- Excavator demolition breaker operation - how to extend its life?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hydraulic breaker versus pneumatic breakers for excavators - differences, disadvantages, applications

- Hammer or hydraulic hammer breaker - which will work better on your excavator?

- Don't choose blindly - find out the real differences between hammer and vibratory hammer

- Hydraulic hammer lubrication - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous