Grooves for hydraulic pile drivers

Grooves are a small component that make a huge difference to everyday work on a construction site. They are the ones that transfer all the impact energy from the pile drivers to the post, pile or pipe, determining whether the component enters the ground quickly, straight and without damage. At Techna Poland, we offer chisels for hydraulic breakers hammers for excavators and hydraulic pile drivers, which are made of hardened steel resistant to abrasion and loads, making them work flawlessly even in difficult terrain. With a variety of diameters and shapes, you can fit a chisel for demolition breaker or pile driver to any task, from installing fences to piling for photovoltaics to heavy engineering structures.

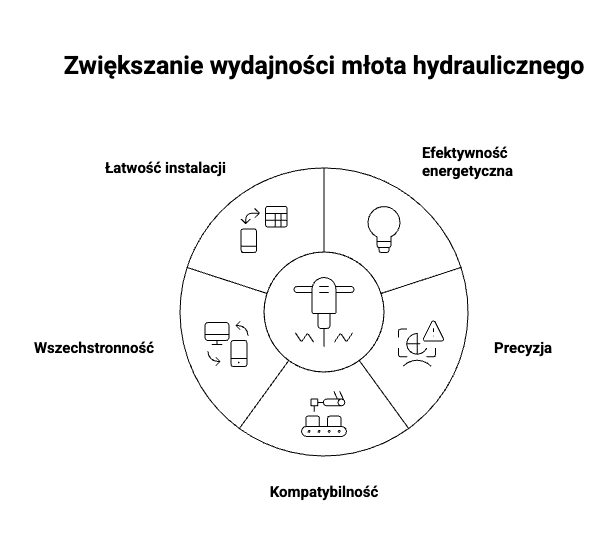

One blade, many possibilities - how to increase the precision and speed of pile drivers with our attachments?

At Techna Poland, we know that every detail of the attachment affects the efficiency of work on site. That's why our hydraulic pile drivers arrowheads are designed to accurately transfer the impact energy from the pile driver to the component being driven, whether it's a steel column, foundation pile, pipe or profile for a photovoltaic structure. Each chisel for demolition hammers for excavators that we offer is made of hardened steel resistant to abrasion and dynamic loads, extending its life and reducing the risk of energy loss during impact.

Thanks to the wide selection of models (PDG100 - 100 mm, PDG150 - 150 mm, PDG200 - 200 mm), you can adapt the chisel for hammer for excavators with demolition breaker to your specific task, maintaining piling stability and reducing damage to the driven parts. This is particularly important when piling for fences, installing lighting poles or installing photovoltaic profiles, where accuracy, speed and repeatability count. If you want to increase the scope of your company's work, all you need is a properly selected mainsail to transform your pile drivers into equipment for future jobs.

| Blade model | Working diameter | Recommended application | Key benefits |

|---|---|---|---|

| PDG100 | 100 mm | Piling of lightweight components: fence posts, installation pipes, aluminium profiles | Lightweight design, fast work and high precision with smaller pile drivers |

| PDG150 | 150 mm | Standard construction and installation work: foundation piles, lighting poles, industrial fences | Balanced weight-to-impact ratio - versatile use in the field |

| PDG200 | 200 mm | Heavy foundation work, piling of steel structures, masts and PV profiles | Maximum impact energy transmission, highest durability and wear resistance |

Chisels for hydraulic breakers - small component, big impact on performance

Not every chisel for hydraulic breakers is the same. We prioritise solutions that reduce energy loss and shorten piling times, while maintaining a high level of precision even in difficult terrain. Our chisels for demolition breakers and pile drivers maintain the verticality of the pile by ensuring that the impact force is evenly distributed over the entire surface of the component. As a result, the risk of the pile deviating from the vertical and being damaged is minimised.

Importantly, our spearheads are compatible with popular machine brands: JCB, CAT, Komatsu, CASE, Doosan, Hyundai, Takeuchi and medium-sized excavators. Their compact design and easy mounting on the hydraulic pile drivers' head allow for quick tip changes, which is crucial when dealing with different phases of a project on the same construction site. If you want flexibility of operation and want to avoid downtime, the right spearhead will allow you to move from light fencing work to heavy engineering tasks without changing attachments.

Chisels for demolition breakers from Techna Poland - see the benefits of shopping in our shop

When you invest in a chisel for demolition breakers from Techna Poland, you are investing in a real improvement in the quality and efficiency of work on any construction site. The spearheads in our range have been designed to work in the most demanding conditions - from uneven, hard ground to areas where silence and lack of vibration harmful to the environment is important. Thanks to the use of high-strength steel alloys, our arrowheads are resistant to cracking, abrasion and deformation even during intensive use. And that's not all.

In addition, we offer:

- - technical advice - we will help you choose the right blade for the type of pile drivers and the type of work being carried out,

- - off-the-shelf availability of parts and accessories - so that your piling work is not interrupted,

- - versatility and compatibility - our spearheads work with many models of machines and pile drivers, giving you the flexibility to take on more projects.

If you're looking for a solution to increase your work rate, piling precision and reduce equipment service costs, spearheads from Techna Poland are the choice that will start to make a real difference to your company's bottom line from day one. Contact us and we'll match a chisel for demolition breaker excavators with the perfect fit for your tasks and investment needs.

| Blade type | Application | Design features | Benefits in practice |

|---|---|---|---|

| Tapered blade | Driving piles, steel and timber poles into the ground | Hardened steel, profiled tip for precise driving | Stable driving, less risk of deflection |

| Flat blade | Piling workpieces with a large contact surface, e.g. pipes and PV profiles | Wide impact head distributes the impact energy evenly over the entire component | Protection of the column surface, reduction of vibrations and noise during work |

| Half-round blade | Works on a wide range of terrain - from soft to clayey ground | Rounded profile for increased ground contact, reducing energy loss | Higher impact performance and shorter pile driving times |

| Specialised blade with adapter | Works with various makes of hydraulic pile drivers (JCB, CAT, Komatsu, CASE) | Interchangeable tip and adapter system for compatibility with different machines | One tool for many tasks - saving time and costs |

| Reinforced chisel for demolition breakers | Heavy pile driving and engineering work in hard soils | High-strength steel, tempered body, abrasion and fracture resistance | Longer blade life and full utilisation of hydraulic hammer power |

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers