Shears, demolition jaws for excavators

Demolition shears and demolition jaws - precision tools for professional demolition

Demolition shears and demolition jaws are key tools in modern demolition and material recycling work. Their use allows efficient and precise cutting and crushing of a variety of construction materials, including steel and concrete. High quality attachments for excavators enable demolition work to be carried out quickly and safely, reducing time and operating costs. That is why Techna Poland offers its customers the best quality excavator attachments in the form of cutting shears and demolition jaws. Many years of experience have allowed us to refine the models we offer. We have focused on high product quality. We invite you to purchase demolition jaws and demolition shears for excavators from various renowned manufacturers JCB, CAT, Doosan, Komatsu, Libhhrer.

Shears 4.0 t - 8.0 t GMS30

Demolition jaws 18.0 t -26.0 t

Steel shears 3-6 t HS25R

One tool, many possibilities - see what the demolition shears and demolition jaws from Techna Poland can do on a demolition site

In demolition work, it is not only the power of the machine that is crucial, but also the quality of the attachment. When it comes to precision cutting of concrete, crushing of reinforced concrete or separation of structural steel, it is not worth making compromises. Demolition shears and demolition jaws for excavators are tools that allow you to combine accuracy with great power and, most importantly, reduce the time of operations and the number of attachments needed. Their use translates into real savings on site - fewer switchovers, fewer machines on site and more done in less time.

| Use of | Benefits |

|---|---|

| Cutting concrete and reinforced concrete | Precision and reduced risk of structural damage |

| Separation of structural steel | Easier material recycling |

| Urban and infrastructure demolition | Time and cost savings, less machinery on site |

Techna Poland offers demolition jaws with different specialisations - from crushing versions to precision cutting and recycling models. They can be fitted to excavators ranging from 20 to 260 tonnes, making them suitable for both urban demolition work and heavier infrastructure work. The right attachment means not only more efficient demolition, but also greater operator safety and better control over every arm movement.

If you want to go deeper into the subject and select an attachment more precisely - also check out the category of crushing jaws, which are designed to work with the most demanding material. And if you're mainly concerned with cutting rebar and steel components, take a look at the cutting shears, where you'll find proposals with a narrow specialisation.

GMS17, GMS30, HRP400...which demolition jaws to choose for your excavator? A practical guide to the models

The demolition jaws available at Techna Poland are divided by machine weight, material type and function, making it much easier to match the attachment to your specific needs.

- If you are working in an urban area and are concerned about time, the HRP series models, for example, are a good choice, combining high crushing power with a compact design and fast cycle times.

- For more demanding tasks, on the other hand, it's worth looking at the GMS series demolition shears, which are designed for heavy-duty use and intensive work with lots of concrete and rebar. The GMS30 model, designed for 24-32t excavators, is an attachment that can cope with even thick structural components, while maintaining precise cutting and fast response times. If you want long reach and 360° rotation, while maintaining adequate working pressure and oil flow control - this direction may prove to be the most cost-effective.

- There are also smaller units on offer, such as the GMS17, which are ideal for excavators of around 20 tonnes and lighter demolitions.

Importantly - all models are designed for quick installation and you will find available consumable parts (blades, bushings, valves) on hand in the shop.

| Model / series | Excavator weight | Special features |

|---|---|---|

| HRP | Various classes (compact) | Compact design, fast cycle, high crushing force |

| GMS17 | ~20 tonnes | For lighter demolition, precise cutting |

| GMS30 | 24-32 t | |

| Function | Benefit | |

| Cutting | Controlled separation of steel and rebar | |

| Crushing | Rapid reduction of concrete and reinforced concrete, easier transport of rubble | |

| Recycling | Possibility to segregate materials, less equipment on site |

g:10px;">Cutting of thick components, 360° rotation, full control of pressure and oil flow

HRP400Combines cutting and crushing functions, 360° rotation

If you use hammers for excavators with demolition breakersin parallel, you can build a versatile working set-up for multiple tasks on the yard - without unnecessary repositioning of equipment and wasted time.

Cutting, crushing, recycling - why can one tool replace several machines?

Separating the functions of crushing, cutting and sorting material still required several separate machines a few years ago. Today, a well-configured set of demolition jaws is all that is needed to efficiently and safely carry out the entire demolition - from the first cut to the final recycling. Especially when it comes to developments in built-up areas or working under time pressure, combining several functions in a single attachment allows you to work faster, with greater precision and lower operating costs.

| Function | Benefits |

|---|---|

| Cutting | Controlled separation of steel and rebar |

| Crushing | Rapid reduction of concrete and reinforced concrete, easier transport of rubble |

| Recycling | Possibility to segregate materials, less equipment on site |

This is clearly evident in the models offered by Techna Poland.

- The HRP400 jaws combine cutting and crushing functions, and thanks to the 360° rotation, it is possible to work in hard-to-reach areas without having to move the machine. Such a solution is especially important when work is carried out at a great height or near structural elements that cannot be disturbed.

- The GMS series demolition shears, on the other hand, offer clean, controlled cutting of steel, which is useful in situations where the material needs to be further processed or segregated.

In many cases, this approach makes it possible to dispense with additional equipment on site. Instead of transporting several machines - you can use one excavator with interchangeable attachments.

If you also need tools for selecting and loading debris - it is worth looking at hydraulic grapples for excavators, which work well for both demolition and construction material logistics.

Bet on strength and precision - demolition jaws and demolition shears for excavators that make a difference in every weight class

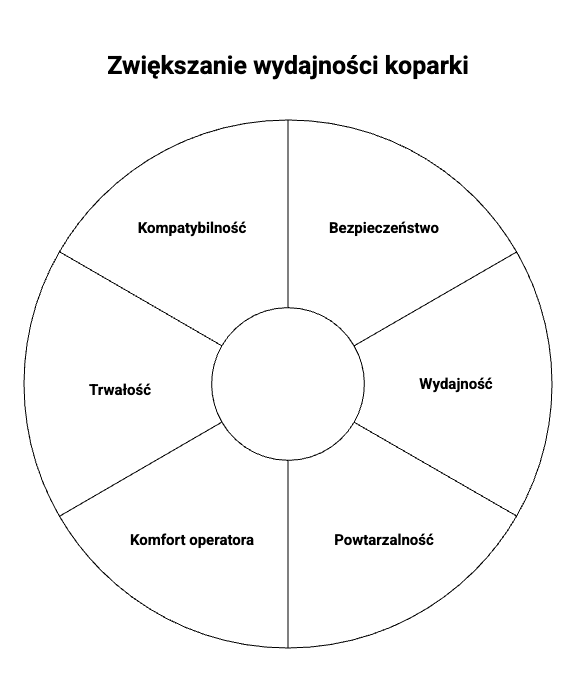

Equipping an excavator with professional demolition attachments is not only a question of productivity, but also of safety, repeatability and operator comfort. That's why it makes sense to choose equipment that has been designed for intensive use and not just adapted 'for trial'. The demolition jaws and shears offered by Techna Poland are industrial-grade equipment designed to perform well on large projects, but also in the day-to-day work of construction companies handling smaller jobs.

The availability of models for different classes of machines - from 20-tonne to much heavier ones - allows you to match the solution to the machinery you already have. And with simple mountings, installation kits and consultancy support, no specialist intervention is required to get the equipment up and running. These are solutions designed to work reliably - not just look good on paper. The materials used, hardened cutting edges, dual actuators, fine-tuned valves and an oil supply with optimum flow are all elements that make a difference in day-to-day operation.

If you're looking for a piece of equipment that will work efficiently for many seasons and is easy to service, check out the current range of demolition shears and demolition jaws available at Techna Poland. Explore the available models, compare parameters and choose a tool that will allow you to work efficiently from day one.

Below the most frequently asked questions by our customers

| Question | Answer |

|---|---|

| How do I choose the right shear or jaw model for my excavator? | The selection depends on the weight and hydraulic parameters of the excavator (pressure, oil flow) and the type of work planned. Contact us and we will help you select the right model. |

| What is the difference between cutting & crushing shears and concrete crushing jaws? | Cutting & crushing shears are used to cut steel and metal, while concrete crushing jaws are used to crush concrete and other building materials. |

| What are the oil pressure and flow requirements? | Depends on the model - check the technical specifications and compare with those of the excavator. |

| What are the maintenance recommendations for the jaws or shears? | Regular lubrication, inspection of the blades and hydraulic parameters ensure a long service life of the attachment. |

| What are the costs for servicing the jaws? | Depending on the intensity of the work - usually limited to servicing and replacing blades or seals. |

| Can I buy blades and spare parts? | Yes - blades, bushings, pins and other consumable parts are available from stock. |

| Do you offer servicing and repair of attachments? | Yes - we provide spare parts and after-sales service. |

| How long does it take to fulfil an order? | For products available from stock - 2-3 working days. For other products - the time is determined individually. |

| Can I test the accessories before purchase? | Yes - we offer performance demonstrations and tests at an agreed location or time. |

| What are the financing options? | We offer leasing and hire purchase - contact us for details. |

Check out the articles on demolition shears and demolition jaws in Techna's guide:

- How to choose concrete pulverizers for excavators - what to look for?

- Demolition jaws or a hydraulic demolition breaker - which is better?

- Operating and servicing crushing jaws - a how-to guide from Techna

- Cutters or demolition breaker for excavators - which to choose? Equipment comparison

- How to choose the right cutting shear for an excavator?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers