Drilling rigs for crawler excavators

Crawler excavators are a mainstay of many construction and earthmoving jobs, especially where stability and strength in demanding terrain are important. An excavator combined with a professional drill rig becomes an effective tool for drilling deep boreholes in soil, rock or concrete. The drilling attachment for excavator arm allows geotechnical, foundation and installation work to be carried out with high precision and efficiency.

The professional hydraulic earth auger provides high rotational force and excellent control over the drilling process. Thanks to the use of advanced gears and robust hydraulic motors, it is possible to drill into various types of ground without the need for additional machinery. Such a set-up is ideal for work in the construction of fences, installation of energy and teletechnical poles, piling and preparation for foundations of buildings and industrial halls.

Hydraulic earth auger - TEHB8000

Drilling rigs for crawler excavators - more than drilling, more than standard

When precision, strength and mobility count on a construction site, crawler excavator drill rigs from Techna Poland turn your machine into a comprehensive tool for special tasks. Thanks to its robust construction, powerful planetary gears and high torque, you can drill foundation, geotechnical, installation or piles for fences and poles regardless of the type of substrate - from clay to gravel to rock or reinforced concrete.

The range includes models such as:

- - TEHB6000 - for 4-6 t excavators, 6000 Nm, drilling in the 100-600 mm range,

- - TEHB7000 - for 6-8 t, 7000 Nm, drilling diameter up to 600 mm,

- - TEHB8000 - up to 8-12 t, 8000 Nm, drilling diameter up to 800 mm,

- - TEHB15000 - up to 10-15 t, 15 000 Nm, holes up to 1000 mm,

- - TEHB20000 - up to 15-20 t, up to 20 000 Nm, diameter up to 1200 mm.

Each of these crawler excavator drills offers operating pressures from 80 to 240 bar, oil flow rates up to 150 l/min and maximum rotational speeds up to 60 rpm, ensuring efficiency and precision when working on any terrain.

| Model | Excavator weight range | Torque | Drilling diameter | Hydraulic parameters | Typical application |

|---|---|---|---|---|---|

| TEHB6000 | 4-6 t | 6,000 Nm | 100-600 mm | Pressure 80-240 bar Flow rate up to 150 l/min Speed up to 60 rpm |

Foundation drilling, geotechnical drilling and column installation |

| TEHB7000 | 6-8 t | 7,000 Nm | Up to 600 mm | Pressure 80-240 bar Flow rate up to 150 l/min Speed up to 60 rpm |

Installation work and drilling in clay, gravel and hard ground |

| TEHB8000 | 8-12 t | 8,000 Nm | Up to 800 mm | Pressure 80-240 bar Flow rate up to 150 l/min Speed up to 60 rpm |

Drilling for piles, foundations and earthworks in rocky terrain |

| TEHB15000 | 10-15 t | 15,000 Nm | Up to 1,000 mm | Pressure 80-240 bar Flow rate up to 150 l/min Speed up to 60 rpm |

Industrial and foundation drilling in hard soil and concrete |

| TEHB20000 | 15-20 t | 20 000 Nm | Up to 1,200 mm | Pressure 80-240 bar Flow rate up to 150 l/min Speed up to 60 rpm |

Heavy industrial, geotechnical and reinforced soil drilling |

Why choose crawler excavator drilling rigs from Techna Poland's range of products?

Drilling rigs for crawler excavators are not just an additional attachment, but a viable investment that increases the scope of jobs and reduces working time on any construction site. Thanks to their robust construction and the use of high-quality steel and planetary gears, you can count on the longevity and reliability of the equipment, even under intensive use.

What do you gain by choosing crawler excavator drills from the range?

- - Versatility - from drilling for foundations, poles, power lines, piles, fences to tree planting.

- - Power and precision - with a torque of up to 20,000 Nm, drilling in hard soils and rock is possible.

- - Time-saving - high working speed while maintaining control of the borehole.

- Operator safety and comfort - thanks to the stability of the crawler excavators and the ease of use of the attachments.

In addition, the hydraulic earth augers offered by Techna Poland are compatible with excavators of the most popular brands (Liebherr, CAT, JCB, Volvo, Doosan, Hitachi) and adaptable to hydraulic quick couplers, thus avoiding additional costs and reducing the time needed to prepare the machine for work.

| Advantage | Description | Advantage for the user |

|---|---|---|

| Versatile use | Drill for foundations, piles, power lines, fences and tree planting | One machine for multiple applications; greater return on investment |

| High torque | Up to 20 000 Nm, with overload-resistant planetary gears | Drilling in hard ground, rock and concrete without loss of precision |

| Robust construction | Body made of high-grade steel, suitable for tough terrain conditions | Long equipment life and resistance to mechanical damage |

| Fast working speed | High working speed while maintaining stability and control | Saves time on every job site - faster jobs, greater efficiency |

| Safety and operator comfort | Stable operation of the crawler excavator and simple operation of the hydraulics | Higher level of safety and reduced risk of operating errors |

| Compatible with | Liebherr, CAT, JCB, Volvo, Doosan, Hitachi - full compatibility with popular excavators | Easy adaptation to existing equipment and avoids additional adaptation costs |

| Adaptation to hydraulic quick couplings | Drills adapted for installation without modifying the hydraulic system | Faster machine set-up and less downtime |

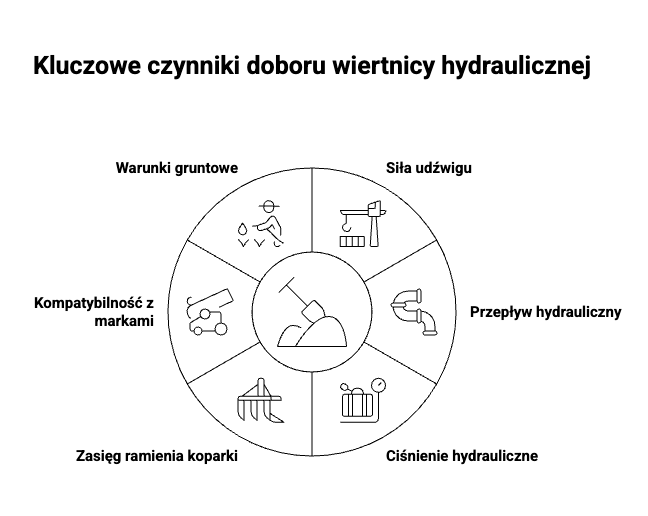

How to choose a hydraulic earth auger for excavator?

Choosing the right hydraulic earth auger depends on the technical parameters of the machine and the specifics of the work. The lifting force, hydraulic flow and pressure, and the working range of the excavator arm are crucial. With the right gearbox and drilling auger, it is possible to work effectively in a variety of ground conditions, from clay and sand to rock or reinforced concrete.

Techna Poland supplies drill rigs compatible with excavators of the most popular brands, such as Liebherr, CASE, Hyundai, JCB and many others. Our solutions are based on the experience of manufacturers with many years of presence on the market and are tested under practical working conditions. Our company makes mounting brackets for all types of quick couplers and excavator arms.

Drilling rigs are equipment that significantly improve work on site - especially hydraulic earth augers for JCB, which are designed for intensive use. A hydraulic earth auger for mini excavators with hydraulic earth auger, valued for its smooth movement, works well in combination with CAT machines. For special tasks, a Kubota forging drill will come in handy, while a hydraulic earth auger for mini excavator with hydraulic earth auger for mini excavator Bobcat is recommended for smaller earthworks.

Applications for everyday work - construction, industry, agriculture

Drilling rigs for crawler excavators are used for, among other things:

- - drilling point foundations and micro piles for halls and industrial buildings,

- -geotechnical and test drilling for soil tests,

- - preparation of boreholes for fences, power and lighting poles and transmission lines,

- - photovoltaic projects,

- - agricultural and forestry tree planting work.

This makes the attachment indispensable for both large infrastructure projects and private projects where accuracy and timeliness are important.

| Application | Description of work | Benefits in practice |

|---|---|---|

| Point foundations and micro piles | Drilling of holes for halls, industrial buildings, steel and prefabricated structures | Stable and precise boreholes, reduction in construction time |

| Geotechnical and test drilling | Soil structure and bearing capacity tests prior to the construction of roads, halls and industrial buildings | Exact analysis of the ground without the need for heavy drilling equipment |

| Boreholes for fences and poles | Preparation of boreholes for electricity, lighting and fence poles | Fast and repeatable drilling - ideal for long fence and installation lines |

| Photovoltaic projects | Drilling for PV panel support structures and power installations | Precise positioning of mounting points, speeding up installation of installations |

| Agricultural and forestry work | Tree planting, preparation of boreholes for stakes and irrigation systems | Increasing the efficiency and accuracy of planting and maintenance of green spaces |

| Private and commercial projects | Small and medium-sized projects where timeliness, mobility and precision are important | Versatile use of a single attachment - from gardens to large construction sites |

Why choose drill rigs from Techna Poland?

The equipment available in our range is designed for long life in harsh conditions.

Techna Poland offers drill rigs for crawler excavators that:

- - have a robust casing resistant to mechanical damage,

- - are equipped with efficient hydraulic motors and seals from renowned manufacturers,

- - can be configured according to the needs of the investment, with a choice of auger diameter and length,

- - are available off-the-shelf with short lead times.

In addition, we provide advisory support in the selection of the model and technical parameters, as well as service and spare parts to guarantee long and trouble-free operation.

Crawler excavator drilling rigs are an indispensable tool in many branches of construction and industry. They enable efficient drilling in all terrain conditions, and their efficiency and reliability make them a key piece of machinery equipment. Thanks to Techna Poland's offer, it is possible to equip an excavator with equipment that realistically increases operational capabilities and allows orders to be completed faster and more accurately. This is an investment that translates into tangible benefits on a daily basis.

A great advantage of our company is our extensive stock and fast dispatch to the customer. The ordered attachments for construction equipment arrive at the construction site ready for use.

| Advantage | Technical description | Benefit in practice |

|---|---|---|

| Robust construction | Housing made of robust materials, resistant to mechanical damage and field conditions | Long service life, reliable in difficult terrain and intensive use |

| Powerful hydraulic motors | High-torque drive with seals from renowned manufacturers | Consistent power and smooth operation even under long-term loading |

| Configurable | Adaptation of auger diameter and length to soil type and project requirements | Greater drilling precision, optimum use of excavator capacity |

| Rapid availability | Drilling rigs available immediately, short lead times and shipment | No downtime - equipment ready for use immediately after delivery |

| Consultancy support | Assistance with model selection, technical parameters and rig configuration | Certainty of a solution tailored to your machine and type of work |

| Service and spare parts | Constant availability of consumables and fast service support | Lower maintenance costs and guaranteed operational continuity |

| Versatile applications | Designed for construction, industry and agriculture | One drill rig - many applications, from infrastructure projects to private projects |

| Extensive stock | Wide range of models and attachments available directly from stock | Fast order processing and certainty of availability of the necessary components |

Check out the articles on hydraulic earth augers in the Techna guide:

- How to choose a hydraulic earth auger for mini excavator?

- How to choose a hydraulic earth auger for excavator?

- How to choose a hydraulic earth auger for backhoe loader?

- Proper operation and maintenance of excavator drilling rigs - what to look out for?

- Types of excavator drill rigs - which to choose for specific tasks and materials?

- New vs. used hydraulic earth auger - which one to choose?

- Buying or renting a hydraulic earth auger - when should I decide?

- Hydraulic earth auger vs. mechanical and pneumatic drill rigs - comparison, differences, applications

- Modern hydraulic earth augers - we present their applications in construction, agriculture and forestry

- The most common failures and defects of hydraulic earth augers - how to solve them?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers