Screening buckets for excavators

Investing in screening buckets is a way for your excavator to start saving time and money from day one. With them, you can sift soil, rubble or humus directly on site, reduce the number of truck trips and prepare the site for the next stages of your project faster. If you are looking for a solution that turns an ordinary excavator into a mobile sorting system, check out Techna Poland's screening buckets and see how to make your business more efficient.

Techna Poland's screening buckets in practice - what do you find on offer?

On today's construction site, every hour counts, and transport and downtime costs can eat into margins faster than work on site. That's why we offer screening buckets on our site that turn an excavator or backhoe loader into a mobile sorting system, allowing you to reclaim soil, humus and aggregate without leaving the project site. Our models, such as the TE-SB2-5 (for 2-5 t machines) or the TE-SB5-9 (for 5-9 t machines), operate at 110-120 bar pressure, an oil flow rate of 30-55 l/min, offering a capacity of 0.05 m³ to 0.2 m³, allowing soil, sand, rubble and compost to be screened right from the excavation.

Manufactured from Hardox steel and fitted with vibration dampers , our screening buckets stand out for their durability and operator comfort, even under intensive use in recycling or roadworks. If you are carrying out earthmoving or demolition work in an urban area, you know how important it is to reduce the number of truck trips and limit dust - screening buckets from Techna Poland allow you to achieve these goals, reducing the number of machines on site and speeding up project completion.

| Model | Purpose | Technical specifications | Benefits in practice |

|---|---|---|---|

| TE-SB2-5 | Excavators and backhoe loaders with a weight of 2-5 t | - Operating pressure: 110-120 bar - Oil flow: 30-45 l/min - Capacity: 0.05 m³ |

- Ideal for work in urban areas - Low empty weight - does not overload the arm - Precise sieving of humus, earth, sand |

| TE-SB5-9 | Excavators 5-9 t | - Operating pressure: 110-120 bar - Oil flow rate: 40-55 l/min - Volume: 0.2 m³ |

- High performance for sifting rubble and compost - Hardox body - abrasion resistant - Vibration dampers - operator comfort |

| Common features of the models | - High-quality Hardox steel for durability - Reduction in dust and number of transport trips - Easy fitting to popular excavator models - Increased efficiency and shorter lead times |

||

Screening buckets for excavators - saving time and costs by working on site

Screening material right on site means real savings, reduced waste transport and faster site preparation for further work. Our screening buckets are used in road construction, recycling, land reclamation, municipal works and agriculture, among others. With their help, you can separate humus for lawns, prepare ballast and separate rubble from soil before loading onto trucks, thus reducing costs and increasing productivity.

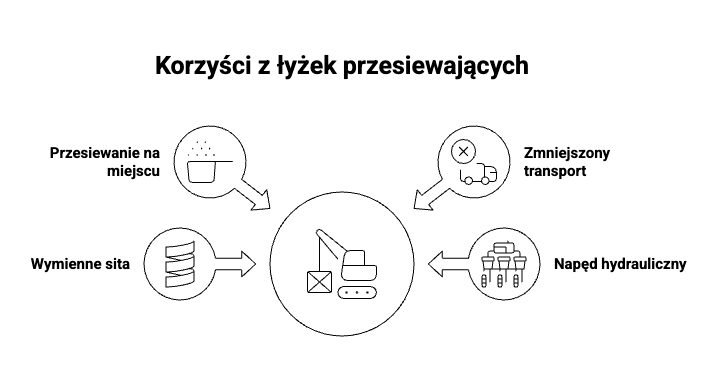

Equipped with interchangeable screens of different mesh sizes, the attachments can be adapted to the material, and the robust hydraulic drive guarantees constant screening efficiency. As a result, one screening bucket excavator does the work that previously required hiring a stationary screening machine and transporting materials, generating additional savings and reducing the carbon footprint of the investment.

A match for your excavator? Not a problem

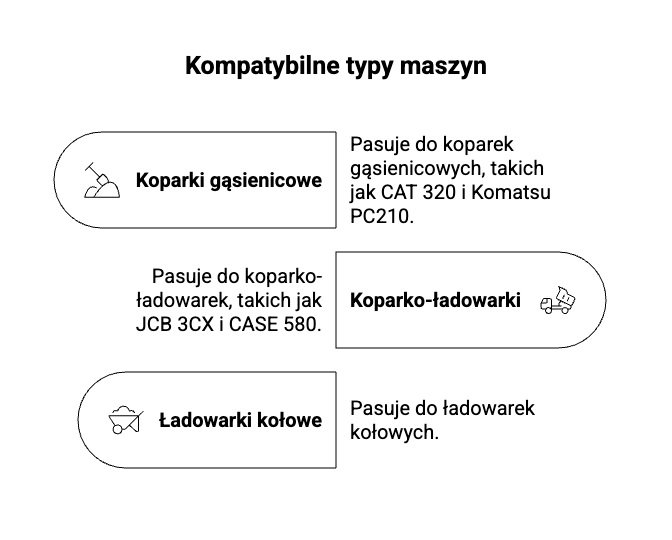

At Techna Poland, we know the importance of quickly adapting attachments to your equipment. Our screening buckets fit crawler excavators (e.g. CAT 320, Komatsu PC210), backhoe loaders (e.g. JCB 3CX, CASE 580) and wheel loaders. We offer pre-fabricated adapter plates between the excavator arm and bucket, avoiding additional modifications and delays - the operator can install the bucket himself on site and start work within minutes of delivery.

If you need support in choosing a model, we provide technical advice, service and access to spare parts to ensure that your investment starts to pay off as quickly as possible. Our solutions are chosen by companies that want to speed up their tasks and gain an edge in tenders thanks to our flexibility.

Why are screening buckets from Techna Poland an investment that pays for itself quickly?

There are many reasons to source screening buckets for soil for excavators from our shop.

- - Working directly on site - no need to transport materials to sorting plants.

- - Reduction in costs and emissions - fewer truck trips, less fuel consumption.

- - Quick adaptation - easy installation to popular excavator and loader models.

- - Performance and reliability - thanks to Hardox steel and robust hydraulic components.

- - Support and parts availability - attachments ready to go when you need them.

If you want to increase the capacity of your fleet and reduce labour costs on any construction site, check out hydraulic pile drivers for excavators and hydraulic pile drivers, which also allow you to expand your company's services. Together with screening buckets, they form a comprehensive set of attachments for excavators that turn your excavator into a tool for special tasks.

| Benefit | Description | Effect for your company |

|---|---|---|

| Working directly on site | Screening of soil, humus and aggregate without transporting materials to sorting plants | Savings in time and logistics costs of up to 30% |

| Reduction in costs and emissions | Fewer truck journeys, reduced fuel consumption and reduced CO₂ emissions. | Ecological and economical solution that improves return on investment |

| Quick to adapt | Easy fitting to most excavators and loaders thanks to standardised mountings | Ready to operate in minutes - no downtime or costly modifications |

| Performance and reliability | Hardox steel body, vibration isolation and precision hydraulics | High screening efficiency and longer equipment service life |

| On-hand support and parts | Availability of spare parts, service and technical advice | Less downtime - certainty that the equipment is always ready for operation |

Frequently asked questions by our customers (FAQ)

| Question | Answer |

|---|---|

| For which applications are screening buckets suitable? | For sorting bulk materials, cleaning debris, preparing compost. |

| Do screening buckets fit all excavators? | There are models available that are compatible with different weight classes. The key is to match the attachment and hydraulics. |

| What are the advantages of buckets with a self-cleaning system? | They prevent clogging of the screen, which increases efficiency, especially with wet material. |

| Can the screens be replaced? | Yes - most models allow the replacement of screens with different meshes. |

| What are the maintenance requirements? | Regular cleaning, inspection of screens, lubrication of moving parts. |

| Does it fit every excavator? | We supply models for machines from 3 to 30 tonnes - we match the specific fleet. |

| Do I need special hydraulics? | No - a standard hammer supply is sufficient, with no additional lines. |

| What are the operating costs? | Low - buckets are simple to operate, cheap to maintain and operate on the same line as the hammer. |

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers