Accessories for hydraulic earth augers

Hydraulic earth auger attachments - a complete development of drilling capabilities

Hydraulic drill rigs are extremely effective tools for drilling into soil, rock, clay or reinforced concrete. However, their functionality and performance depends not only on the drive and gears themselves, but also on the right accessories. Techna Poland offers a wide range of accessories for hydraulic earth augers, which allow the working set to be adapted to the specific type of work, terrain and type of base machine.

The most important accessory for drilling rigs are the drill augers. Available in various diameters and lengths, they allow drilling for point foundations, piles, fence posts, road signs, lighting and photovoltaic systems. Depending on the ground conditions, standard augers, spiral augers, augers with reinforced blunt teeth, cutters or spearheads for rock and reinforced concrete are used.

Varied drilling rig accessories - match the auger to the job and conditions

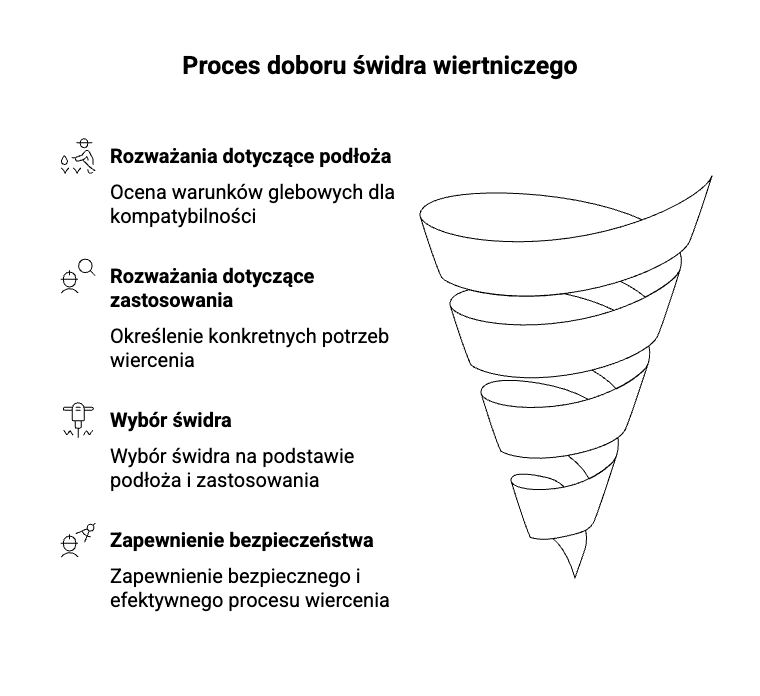

The choice of drilling auger has a direct impact on the quality, speed and safety of the well. On the face of it, it's a simple element, but when you get into the details - diameter, length, spiral geometry, type of teeth or bits - you start to notice how important it is to match the ground and the specific application. There's no point in using a clay drill where you're going into reinforced concrete. If you want to avoid downtime and replacing worn bits every other day - rely on parts for earth augers that are matched not only to the material, but also to the speed of your work.

You'll find standard and spiral augers, equipped with reinforced blunt teeth, rock bits and cutters that better penetrate hard ground layers. This gives you the freedom to plan boreholes for piles, point foundations, fence posts or photovoltaic systems - whether you are working on dry gravel or wet clay.

And if you're using the equipment for a variety of tasks, look out for compatibility - the hydraulic earth auger attachments forexcavators and mini loadersat Techna Poland are available to fit both excavators and mini loaders, including, among others, the attachment for wheel loaderscategory.

For roadworks and installation work, the hydraulic earth auger for mini excavator with hydraulic earth auger will be indispensable, ideal for fast drilling in hard surfaces. Noteworthy among CAT equipment is the hydraulic earth auger for CAT backhoe loaders, which combines power with precision. The Kubota excavator drill rig is a practical solution for installation companies, while the Bobcat hydraulic earth auger for excavators works well for earthworks and fencing.

Performance not just in the engine - power starts with the drill bit

Many people know the feeling when equipment has good performance, but in practice something does not work as it should? Often, the problem lies precisely in the wrong attachment. The parts for earth augers you choose will determine whether your machine can cope with more difficult ground. Without the right auger, even the most powerful drill rig will not show its full potential. Therefore, before you fire up the engine, think carefully - is the accessory you are using really suited to the type of work and terrain conditions?

At Techna Poland, you will find accessories compatible with a variety of drives, designed for maximum durability and load resistance. By choosing parts for earth augers with the right helix pitch, angle or tooth type, you can not only speed up your work but also significantly reduce wear and tear on your equipment. These aren't details - they're differences that you can see in your day-to-day work.

If you're using a mini excavator-type machine, be sure to also check out hydraulic earth augers for mini excavators - all available attachment accessories are fully compatible with them.

| Soil type | Type of drill bit / auger bit | Characteristics and application |

|---|---|---|

| Soft soil, sand, garden soil | Standard auger with large helix pitch | Fast spoil removal and high drilling speed. Ideal for garden work and light installations. |

| Mixed soils, clay, gravel | Reinforced drill bit with hardened teeth | Increased adhesion to the ground, effective penetration of harder ground layers without slipping. |

| Hard ground, rock, concrete | Auger bit with widia tip or replaceable teeth | Superior wear resistance. Ideal for drilling in rocky ground and industrial work. |

| Moist and unstable ground | Short-stroke auger bit with extra blades | Improved borehole stabilisation and control of excavated material. Works well in peat, clay and foundation work. |

| Variable-structure soils | Universal drill bit with interchangeable tips | Flexible use - one drill bit for different types of ground, ideal for companies handling diverse projects. |

A drill for a special task - when is it worth reaching for auger bits for difficult tasks?

Some projects are not forgiving of mistakes - hard concrete, rock, reinforced concrete or compact clay layers can immobilise equipment for long periods of time if you use an auger that was not designed for this. That's why, in these situations, it's a good idea to go for augers fitted with specialised bits designed for precision drilling in materials with increased hardness. Key here are carbide cutters, strong teeth and robust breakaway bits that, at higher torque, enter the rock without overloading or risking breakage.

Such accessories will be indispensable especially if you are working on the installation of pole foundations, masts, railings or solar installations, where the accuracy of the borehole counts. And if you frequently change work locations and base machines, remember that the components available in this category can easily be used on tracked equipment - including parts for excavators. In practice, this means one thing - you don't need a new set of augers for every machine. All you need is a well-thought-out attachment that effectively develops the drive capabilities and allows you to operate flexibly.

Want to use the full potential of your drill rig? Select professional parts for earth augers and be prepared for any field conditions. Check out all available options and expand your working set-up with Techna Poland - reliably, for a long time and exactly as you need it.

| Auger / drill bit type | Application | Key features | Advantages at work |

|---|---|---|---|

| Auger with tungsten carbide cutters | Rock, reinforced concrete, concrete, high-hardness substrates | Extremely hard, wear-resistant cutters, suitable for high torque | Effective drilling in concrete and rock without overloading the drive |

| Auger with replaceable cutting teeth | Compact clay soils, gravel, concrete with admixtures | Quick tine changes, modular design, impact load resistance | Longer service life and lower operating costs - no need to replace the entire auger bit |

| Auger with breaking tip | Rock layers and hard ground with uneven structure | Powerful central tip that breaks up the structure of the material in front of the working spiral | Increased drilling efficiency and reduced risk of drill bit jamming |

| Variable pitch spiral auger | Works on diverse terrain, rock-clay-sand | Dynamic excavation, less resistance to soil movement | Versatile - one auger bit for many types of soil |

| Hardened steel auger with reinforced cutting edge | Industrial applications, drilling for foundations of masts and steel constructions | Thick working helix, resistant to deformation and abrasion | Stable operation with large hole diameters and high torque |

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers