Crusher jaws

Demolition jaws for excavators and mini excavators - a key tool in demolition work

Demolition jaws are an extremely important tool used in construction and demolition. Mounted on the arm of excavators and mini excavators, they enable concrete, steel and masonry structures to be demolished quickly, efficiently and safely. Thanks to their specialised design, they allow for precise crushing and separation of materials, facilitating their further processing and recycling.

Demolition jaws 18.0 t -26.0 t

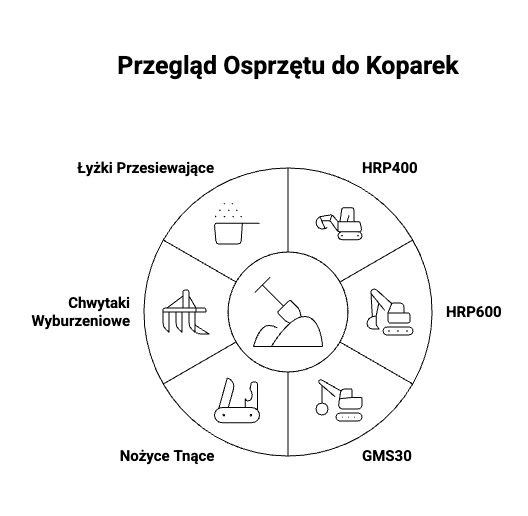

HRP400, HRP600, GMS30 - meet the crusher jaws that really get the job done

When choosing demolition attachments for excavators, it's worth taking a practical approach. It's not just about the tool being robust. What matters is how it performs on a day-to-day basis, whether it can handle different materials and whether it can keep up the pace on site throughout the day.

In the case of the crushing jaws in the Techna Poland range - such as the HRP400 HRP600 or the GMS30 - it is immediately apparent that these are no accidental designs. Each of these models has been fine-tuned for real-world performance, to fit a specific class of excavator and to withstand heavy use.

- The HRP400 will suit machines from 18 to 26 tonnes, offering a full range of functions in a compact form - with 360° rotation, powerful cylinders and a central tine. The HRP600 is for heavier excavators (26-40 tonnes) that work with thick concrete and reinforced concrete on a daily basis. Here, the longer jaw spacing, greater leverage and higher working weight translate into faster and more accurate work.

- The GMS30, on the other hand, a classic concrete pulverizer for excavator in the 24-32 tonne class, is the solution for those looking for a compromise between strength and manoeuvrability - with a body made of high-strength HARDOX steel and powerful working knives.

Each of these models can be conveniently supplemented with other tools from Techna Poland's range - such as cutting shears, which are great for complementing operations on steel structures, or demolition shears, which make sorting and moving rubble easier. For more specialised tasks, screening buckets that improve the preparation of material for recycling are also worth checking out.

Crusher shears for excavators - crushing concrete, steel and rock. One tool, multiple uses

Modern construction sites require flexibility. Sometimes you need to cut a steel beam, other times you need to deal with a thick layer of concrete, and then deal with clearing the site of smaller pieces. Concrete pulverisers for excavators give you the ability to combine these activities in one continuous process, without having to change attachments every ten minutes or so. This puts the operator in full control of the workflow and allows the company to complete the job faster and without additional equipment.

* Models such as the HRP600 and HRP400 not only feature reinforced jaws and working teeth, but also a rotating head that allows full adjustment to the current working angle. This greatly speeds up demolition and gives better precision, especially in tight housing or at unusual approach angles. The concrete crusher shears in this category are designed to handle material without the need to 'push' with machine force, reducing wear on the excavator arm and reducing the risk of failure.

Importantly, these tools are not limited to one class of machine. You will find equipment for both 18-tonne excavators and those over 40 tonnes. If you're looking for concrete shears that not only look robust, but actually speed up your field work, it's a good place to start.

| Application | What you get |

|---|---|

| Crushing concrete, steel and rock with one tool | Versatile use - cutting, crushing and tidying up the site without changing attachments |

| Work in a variety of terrain conditions | Full control of workflow - fast job completion and less need for additional machines |

| Models HRP600 and HRP400 | Reinforced jaws and working tines, rotating head for working at any angle |

| Working in hard-to-reach places | Precise adjustment of the working angle - ideal in tight spaces and during spot demolitions |

| Machine protection and longer equipment life | Reduced overpressure design - less strain on excavator arm and lower risk of failure |

| Suitable for different machine classes | Models compatible with excavators from 18 to over 40 tonnes - flexibility to match equipment to project scale |

| Increased team efficiency | Less downtime, greater precision and higher productivity without the need for frequent attachment changes |

It's also worth checking out the range of bush breakers hammers for excavators if you're operating on a variety of material and need to complement your kit with a powerful point forging tool.

Refined design, impressive crushing power - check out what makes the concrete pulverizer for excavator from Techna Poland stand out.

Not everything heavy works effectively. In demolition attachments, it is the ratio that matters most: weight to working force, material strength to plasticity and cutting efficiency to material resistance. This is why the design of the jaws available from Techna Poland is based on proven solutions and premium components. A body made of hardened HARDOX steel, teeth with interchangeable tips, hydraulics adapted to high working pressure, the possibility of full rotation - these are not extras, but standard.

A well-chosen concrete pulverizer for excavator should, above all, work smoothly, without overloading or jumping. That's why models such as the GMS30 or HRP600 have a reinforced arm design, optimum blade spacing and precise oil flow control. Importantly, this equipment does not require any specialised adaptation of the excavator - all that is required is to select a handle and quickly connect it to the existing installation. This means less time preparing the machine and a quicker return to work after each attachment change.

The availability of wear parts and advisory support is also an added benefit of the range. Should you need to replace bushings, valves or arrowheads, everything is available off-the-shelf. So you are guaranteed that your equipment will be ready to go when you really need it.

Take a look at the available crushing jaw models and choose a solution that can handle any type of material - without compromise and without stress. At Techna Poland you will find equipment that simply works.

| Application | What you get |

|---|---|

| Crushing of concrete, steel and other hard materials | Body in hardened HARDOX steel, replaceable tine tips and hydraulics adapted to high working pressure |

| Work under demanding demolition conditions | Optimum weight/working force ratio - maximum effectiveness with minimum machine load |

| Models GMS30 and HRP600 | Reinforced arm design, precise oil flow control and full head rotation capability |

| Quick connection and operation | No need to modify the excavator - just a matching handle and standard hydraulic connection |

| Continuous operation and reduced downtime | Availability of consumable parts - bushings, valves and spearheads - without long waits for deliveries |

| Professional consulting support | Assistance in selecting the right model and attachment configuration for excavator type and nature of work |

| Use in a variety of industries | Ideal for construction, industrial demolition, recycling and construction waste processing |

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers