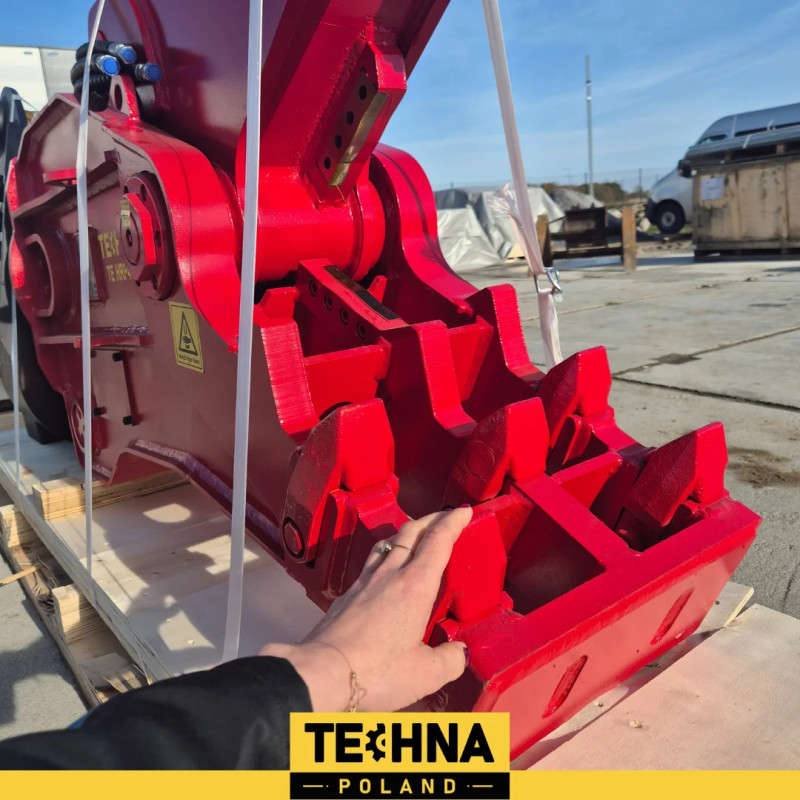

HRP400 crushing jaws 6.0 t - 11.0 t

HRP400 +48 604 108 143

+48 604 108 143Monday - Friday 8.30 - 17.30

HRP400 crushing jaws - A precision tool for demolition challenges

The HRP400 crushing jaw is a tool that prioritises strength and precision, ideal for demolition and recycling work. If you're looking for a solution for excavators weighing between 6 and 11 tonnes, the HRP400 provides unparalleled efficiency, enabling you to quickly crush concrete, brick and shred building materials. Its robust design and innovative hydraulic technology make it a tool that is up to the demanding tasks on site.

| Data sheet | Specification |

|---|---|

| MACHINE WEIGHT | 6-11 t |

| HYDRAULIC ROTATION | 360° |

| HARDWARE WEIGHT | 630 kg |

| Length | 1480 mm |

| WIDTH | 960 mm |

| WORKING PRESSURE | 250-280 bar |

| OIL FLOW | 50-70 l/min |

| CRUSHING POWER | 120 t |

| SIŁA ZAMYKANIA Z TYŁU | 80 t |

| SIŁA ZAMYKANIA Z PRZODU | 35 t |

Cutting force and precision - What makes the HRP400 crushing jaws unique

With a weight of 630 kg, the HRP400 crushing jaw generates as much as 120 tonnes of cutting force to effectively crush concrete and steel. Added to this is a closing force of 80 tonnes, ensuring reliability in the toughest working conditions. With 360° rotation and a hydraulic system, operating the hammer becomes extremely smooth, enabling fast and accurate manoeuvres.

Performance that enhances efficiency

The HRP400 is a tool that combines high cutting power with exceptional durability. Its robust construction and wear-resistant material mean it will perform in all conditions, even in the most intense environments. Thanks to its 360° rotation, you have full control over every stage of the work, and the optimised hydraulic system ensures fast operations with minimal energy consumption. Thanks to the high oil flow and optimised operating pressure, working with the HRP400 is more efficient and less time-consuming. What's more, replacing working parts such as teeth and knives is quick and easy, saving further time by eliminating long downtimes.

Versatile use and compact design of the hydraulic jaws

The HRP400 is ideal for both primary and secondary demolition of concrete structures, as well as recycling of building materials. Thanks to its advanced rebar cutting system, it effectively separates steel from concrete, which is important for further processing of raw materials. The compact design of the crushing jaw makes the tool ideal for working in hard-to-reach areas such as basements, narrow corridors or in dense urban areas.

Efficiency in difficult environments

The HRP400's performance and reliability do not end with its precise technical parameters. Thanks to an innovative noise dampening system, working with this tool is significantly less disruptive to both the operator and the environment. The aforementioned vibration reduction has the effect of reducing the load on the excavator, which prolongs its life. These features make the HRP400 an ideal choice for work in urban areas where silence and comfort are key.

Why choose the HRP400 crusher jaws?

If you want a tool that will speed up the demolition process and reduce downtime, the HRP400 is the choice that guarantees high efficiency. Thanks to its advanced technology and robust design, it's a solution that will help you increase the speed of your projects while ensuring reliability and precision in operation.

Check out other models:

For more information or inquiries, please visit our contact or our page.

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers