Mixing buckets for mini loaders

Do you want your mini-loader to work more and also make money when you need concrete on site? Mixing buckets for mini loaders allow you to prepare fresh mix exactly when and where you need it, without downtime or wasted material. It's a way for one machine to do more jobs in less time, speeding up paving, fencing or soil stabilisation on any construction site.

Concrete on site, exactly when you need it - mixer buckets for mini loaders

The mixer buckets for mini loaders in the Techna Poland range have been developed for crews who want to work smoothly and independently. With a working capacity of 0.35 m³, compact dimensions (length 1553 mm, width 1086 mm, height 986 mm) and a robust hydraulically driven mixing shaft, you can prepare exactly as much concrete or mortar as you need - anywhere, without wasting material or nervously waiting for delivery.

This solution will work well for:

- - fence foundations ,

- - paving work ,

- - soil stabilisation

- - and for emergency repairs where reaction times are crucial.

Mixing buckets for mini loaders eliminate the need for stationary concrete mixers and allow the mix to be prepared exactly on site, reducing logistics and transport costs. One mini-loader, equipped with a mixer bucket, becomes a mobile concrete production point that starts earning money from day one.

| Advantage | Description of operation | Benefit for the user |

|---|---|---|

| Concrete always on site | The mixing bucket prepares the mix directly on site, no transport required | No downtime, time saving and full control over material quantities |

| Hydraulic mixer drive | Robust working shaft with hydraulic drive ensures thorough mixing of mortar or concrete | Uniform mix consistency and reduced risk of mixing errors |

| Compact dimensions | Length 1553 mm, width 1086 mm, height 986 mm - ideal for working in tight spaces | Free mobility and work even in hard-to-reach places |

| Working volume of 0.35 m³ | Allows just the right amount of mix to be prepared without over-mixing or wasting material | Economical use of raw materials and lower investment costs |

| Versatile application | Ideal for foundations, soil stabilisation, paving work and rapid repairs | One unit, multiple applications - greater flexibility on the construction site |

Instead of a concrete mixer and waiting - how do Techna Poland's mixing buckets speed up work on site?

Comfort is hard to come by in the field, and traditional concrete mixers don't always work well where mobility and speed are important. The mini loader mixer buckets available from Techna Poland are designed to work wherever you need to prepare fresh concrete mix exactly when you need it. The equipment works with mini loaders from brands such as Bobcat, JCB, CAT, Gehl, Avant or Kubota, allowing you to exploit the potential of your existing fleet without having to invest in additional equipment.

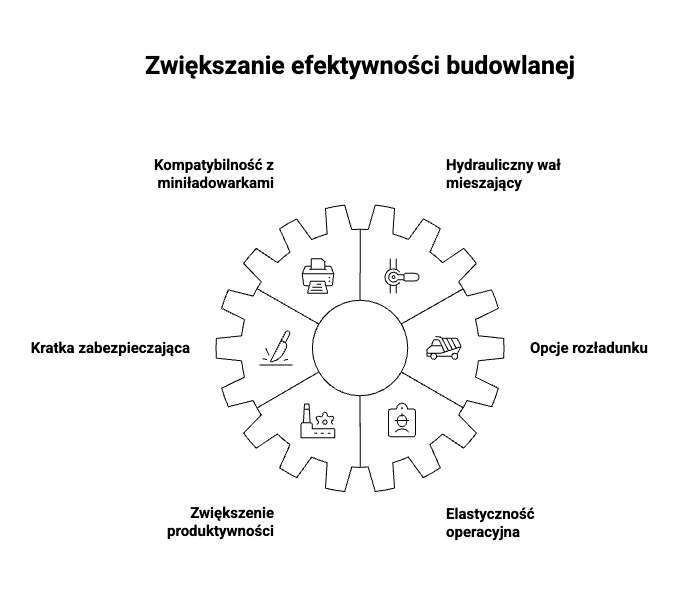

The equipment includes a hydraulic mixing shaft, a debris screen and an unloading system via a central drain hole or by swinging the bucket, allowing full control over the mix preparation process and its pouring exactly where it is built. Instead of waiting for a delivery from the concrete plant, the operator can prepare the required amount of mix in a few minutes, keeping the work flowing and the project running smoothly. It's a solution that allows construction, paving and installation companies to operate flexibly, increasing the speed of jobs without compromising quality.

If you want to get even more out of your mini-loader, also check out screening buckets for humus and aggregate recovery, chain tren chers for mini-loaders for fast linear excavation and demolition grapples for excavators to increase your company's range of services.

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers