Hydraulic grapples for excavators

Want your excavator to work faster and more accurately during demolition and recycling? Techna Poland's demolition grabs are attachments that speed up sorting, make debris loading easier and allow you to accurately separate steel from concrete, reducing the number of machines on site. If you're looking to increase efficiency and reduce the cost of completing jobs, check out our range and see how demolition grabs will transform your company's daily operations.

Grapples that make a difference - precision and power in every demolition job from Techna Poland

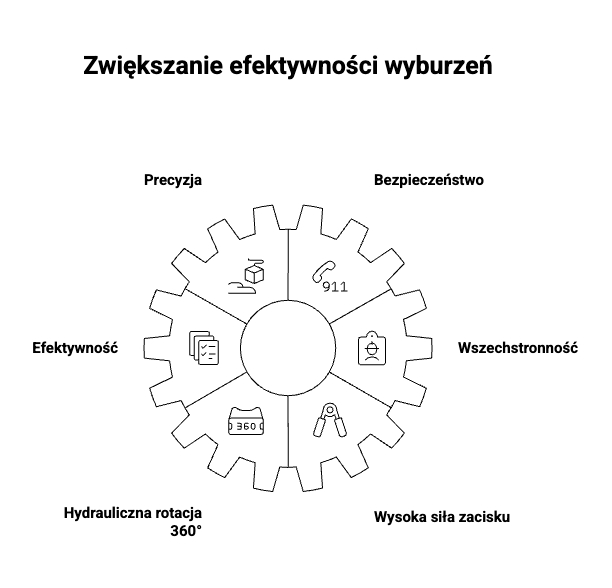

Demolition and recycling not only require strength, but above all precision. This is why at Techna Poland we offer hydraulic grapples for excavators to speed up demolition work, increase safety on site and reduce the number of machines needed. Thanks to their 360° hydraulic rotation and high clamping force, the grapples make it easy to grasp, sort and crush construction elements, from reinforcing steel to thick blocks of concrete.

Our range includes models such as the TE-SG2-5 (for 2-5 t excavators), TE-SG6-9 (6-9 t) and TE-SG12-17 (12-17 t). Each is characterised by:

- - large jaw opening (from 970 mm to as much as 2,100 mm) ,

- - a robust construction made of Hardox or NM400,

- - and easy installation on popular excavator brands (JCB, CAT, Komatsu, Doosan, Volvo).

This makes your excavator a multifunctional tool that works well in tight urban spaces as well as heavy industrial and quarry work.

If you're planning to expand the capabilities of your fleet and reduce waste disposal costs, also check out the screening buckets, which allow aggregates to be recovered directly on site, increasing the efficiency of the entire work cycle.

| Model | Excavator weight | Jaw opening | Construction material | Compatibility |

|---|---|---|---|---|

| TE-SG2-5 | 2-5 t | approx. 970 mm | Hardox / NM400 | JCB, CAT, Komatsu, Doosan, Volvo |

| TE-SG6-9 | 6-9 t | approx. 1500 mm | Hardox / NM400 | JCB, CAT, Komatsu, Doosan, Volvo |

| TE-SG12-17 | 12-17 t | up to 2100 mm | Hardox / NM400 | JCB, CAT, Komatsu, Doosan, Volvo |

Demolition, recycling, loading - how to choose a demolition grapple to work faster and more cost-effectively

In everyday demolition work , time, safety and reducing waste transport costs are important. The demolition grabs in our range provide precise gripping of structural components, allowing the operator to accurately separate concrete from rebar and quickly load material for recycling or disposal. Hydraulic mechanisms characterised by high clamping force (working pressure of up to 350 bar, oil flow of up to 200 l/min on the TE-SG12-17 model) guarantee a secure grip even on large and heavy workpieces.

Thanks to the full rotation of the gripper, the operator can precisely position the attachment in any position, which increases the work rate and reduces the risk of damage to the environment during demolition. This makes hydraulic grapples for excavators applicable not only in demolition projects, but also in construction waste segregation, recycling and during clean-up work on construction sites.

For companies wishing to extend the scope of work and carry out orders comprehensively, we also recommend hydraulic pile drivers for excavators, which allow piling for fences, photovoltaics or road infrastructure, completing the machinery park with piling function without the need to invest in separate equipment.

| Model | Excavator weight | Jaw opening | Construction material | Compatibility |

|---|---|---|---|---|

| TE-SG2-5 | 2-5 t | approx. 970 mm | Hardox / NM400 | JCB, CAT, Komatsu, Doosan, Volvo |

| TE-SG6-9 | 6-9 t | approx. 1500 mm | Hardox / NM400 | JCB, CAT, Komatsu, Doosan, Volvo |

| TE-SG12-17 | 12-17 t | up to 2100 mm | Hardox / NM400 | JCB, CAT, Komatsu, Doosan, Volvo |

One piece of equipment, many applications - discover the demolition grabs that will increase your company's range of services

The hydraulic grapples for excavators offered by Techna Poland are not just attachments for excavators - they are tools for recycling, site clean-up and preparing materials for transport. Their versatility allows you to reduce the number of machines needed on site, and their use really reduces the time it takes to complete jobs. Thanks to interchangeable tongs and wear-resistant components (Hardox, NM400), our grapples remain highly effective even when working in difficult terrain or under intensive use.

For companies involved in heavy industrial demolition, quarry work and recycling, Techna Poland's demolition grabs will be the ideal choice to safely handle materials and reduce operating costs. Plus, with the ability to be easily assembled and fitted to popular models of excavators, the attachments are ready to go as soon as they arrive on site, avoiding downtime.

If you want your excavator to be ready for any job, see also the hydraulic pile drivers for quick expansion of your fleet's capabilities for precision piling in any ground conditions.

Frequently asked questions by our customers (FAQ)

| Question | Answer |

|---|---|

| How do I choose a grapple for excavators? | The choice of grapple depends on the weight of the machine, the hydraulic parameters (pressure, oil flow) and the type of work planned. Contact us and we will help you choose the right model. |

| Do grapples for excavators fit different brands? | Yes, we offer grapples compatible with many brands of excavators. If necessary, we adapt the attachment to the specific machine model. |

| Can the demolition grab be used with a mini-excavator? | Yes, there are demolition grapple models available that are designed for mini excavators. However, it is important to select the right model for the weight and hydraulic parameters of the machine. |

| What are the typical applications for demolition grabs? | Demolition grabs are used in the demolition of buildings, the dismantling of steel and concrete structures and when recycling building materials. |

| What are the operating pressure and oil flow requirements? | These requirements vary depending on the grapple model. Before purchasing, check the technical specifications of the equipment and compare them with those of the excavator. |

| Do the demolition grabs have hydraulic rotation? | Yes, all models of our demolition grapples are equipped with 360° hydraulic rotation, which increases precision and efficiency. |

| Are the demolition grabs easy to install? | Yes, the grabs are designed for easy assembly and disassembly. Depending on the model, they can be mounted on pins or with quick-release couplings. |

| What are the maintenance recommendations for demolition grabs? | Regular lubrication, checking the condition of the jaws and monitoring the hydraulic parameters are key to the long life of the grapple. |

| Do you offer spare parts for demolition grabs? | Yes, we provide service and spare parts availability for our products. |

| What are the financing options for purchasing a demolition grapple? | We offer various forms of financing, including leasing and hire purchase. Contact us for details of the offer. |

| How long does it take to complete an order? | The lead time depends on the availability of the model in question. For in-stock products, dispatch is usually within 2-3 working days. |

| Can I test the demolition grapple before purchasing? | We offer demonstrations of the operation of the grapple and tests under certain conditions. Contact us to arrange a demonstration. |

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers