Choosing the right attachment for excavator loaders can be a tricky business - especially if you haven't worked with hydraulic earth augers before. At first glance, everything looks the same: planetary gear, shaft, auger... However, if you disregard a few key technical parameters, you may end up with a model that is too weak, hydraulically incompatible or simply inefficient for your working conditions.

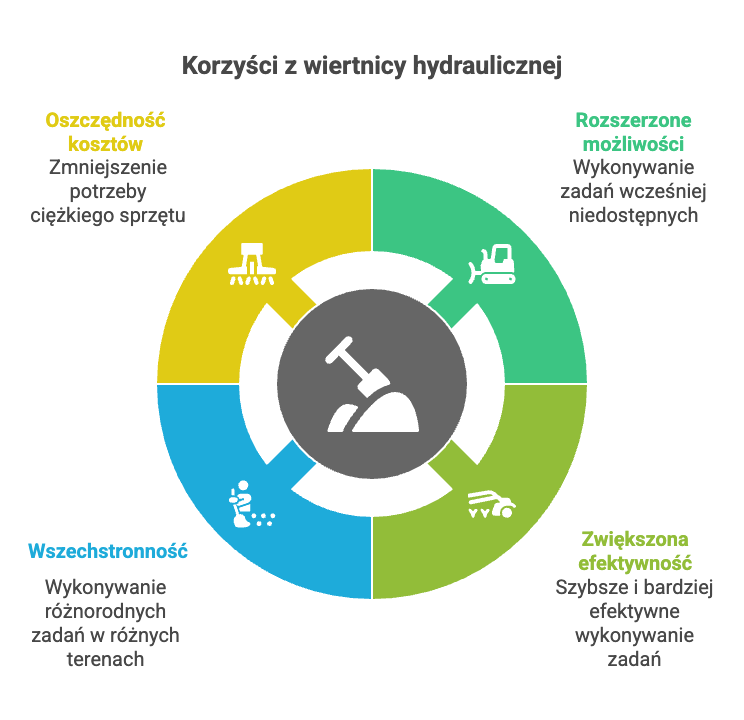

Why is a backhoe loader and hydraulic earth auger a duo that will enhance your capabilities on site?

If you have a backhoe loader and are considering expanding its functionality, a hydraulic earth auger is one of those additions that can really change the rules of the game. A well-chosen model will not only allow you to drill for fences, signs or plantings, but also to complete jobs that were previously out of your reach - especially when it comes to light geotechnical work or drilling for garden foundations.

What makes backhoe loaders so versatile is their mobility and accessibility. And when you combine them with the right hydraulic earth auger, you can use their potential much more effectively. Of course - this kit won't replace a drill rig on a 20-tonne crawler excavator, but if you're operating in the service sector, flexibility and speed often count more than power alone.

That's why the hydraulic earth augers for backhoe loaders available from TechnaPoland are designed to extract the maximum potential from this class of machine. The compact models, optimised for oil flow and lifting capacity, enable clean, precise drilling even in more difficult terrain, without the need for heavier equipment.

Among the equipment that enhances the capabilities of construction machinery, the hydraulic earth auger for excavators used in many construction sectors is particularly popular with JCB. Drills designed for CAT excavators are characterised by exceptional stability and rotational power. A hydraulic earth auger for mini excavators from Kubota is well suited to smaller machines, while drill rigs for Bobcat construction machines combine mobility with high performance.

How to choose the parameters of a drill rig for your backhoe loader to avoid costly mistakes?

Before you make your purchasing decision, pause for a moment at the specifications. Because although many models look similar, mismatching the technical parameters for your machine could end up with inefficient operation or even damage to the hydraulic system.

The first consideration should be the weight of the carrier - that is, the weight of your backhoe loader. Most hydraulic earth augers for this class of machine work effectively with vehicles weighing between 7 and 12 tonnes. Don't choose models designed for 15-20 tonne tracked excavators - they will be too heavy and overload the hydraulic system.

Torque is another key parameter - the higher the torque, the better the drill can cope with dense, compacted soils. For garden applications, 1,000-2,000 Nm is sufficient, but if you plan to drill for piles or clay soils, for example, choose models with more than 3,000 Nm of torque.

You also cannot overlook values such as:

- oil flow (l/min) - this should be in line with the capacity of your machine,

- operating pressure -this affects the drilling force,

- the weight of the drive unit - a rig that is too heavy may reduce stability, one that is too light may lose grip.

In TechnaPoland's offer you will find models of hydraulic earth augers precisely described in this respect. It is worth comparing and selecting equipment that not only "fits", but will perform at 100% capacity.

Stability, mobility, performance - which features of hydraulic drill rigs for backhoe loaders matter most when drilling?

When choosing drilling equipment, it is worth looking beyond the drill rig itself. The type of machine you fit it to makes a huge difference to productivity and safety. A backhoe loader is a popular choice for many reasons - but it also has its limitations, which you need to know.

If you compare it with a tracked excavator, the difference is immediately apparent. Caterpillars give more stability on muddy, gritty ground. This is why hydraulic earth augers for excavators are used for geotechnical and foundation tasks - they simply handle where other machines bog down.

The backhoe loader, on the other hand, has the great advantage of mobility - it works well in urban areas, for seasonal work and even for companies that offer a wide range of services. A mini excavator? Ideal for light garden work, but won't cope with larger boreholes.

So, before you decide on a particular drill rig, always weigh up the technical specifications against the characteristics of your machine. Remember - what works great on one may simply be useless on another.

When is a hydraulic earth auger for excavator a better choice than other solutions?

You don't always have the need to invest in heavy equipment. Often, a back hoe loader with a well-matched hydraulic earth auger will prove to be the most cost-effective solution - both in terms of purchase cost and versatility of operation.

Such a set will prove useful in, e.g:

- road works - drilling for signs, signalling,

- agriculture - installation of fences, irrigation systems, etc,

- municipal services - tree planting, installation of lighting poles,

- gardening - planting, palisades, pergolas.

Thanks to the fact that backhoe loaders are often already in stock at construction companies, the purchase of the drill itself is a small cost compared to buying a new excavator or crawler set. And the efficiency? If you choose equipment suited to the conditions - it will be more than adequate.

Check out the specific hydraulic earth augers for backhoe loaders on our shop page that work best in such a set-up - including the TEHB3500, TEHB5000 and TEHB8000 models.

Maintenance and operation of hydraulic earth augers - how to extend the life of the equipment and avoid breakdowns?

Although the drill rig itself appears to be a 'maintenance-free' piece of equipment, it - like any machine - requires regular inspection and servicing. Otherwise, sooner or later, leaks, drops in performance or torque problems will occur. And then - neither the well will be drilled, nor the job completed.

In day-to-day operation, three things are most important:

- lubrication of moving points - i.e. bearing points, hinges, rotating parts,

- checking the oil level in the planetary gears,

- checking hydraulic connections for leaks - even the smallest leak is a signal that action is needed.

Regular maintenance is also recommended - ideally every 100-150 motoring hours, depending on the intensity of work. Always use genuine spare parts - because while cheaper replacements may be tempting, they often don't hold up and cause further breakdowns.

It's also good practice to clean the machine after a day's work - especially if you're working in clay, mud or wet terrain. This is seemingly nothing, but can significantly extend the life of the entire drive unit.

If you are not sure what maintenance you should do yourself and what is better to have done by a service centre, contact TechnaPoland. They will help you establish a maintenance schedule and select the right lubricants and oils for your rig model.

Real-life examples from the construction site: how did the right rig model halve the work time?

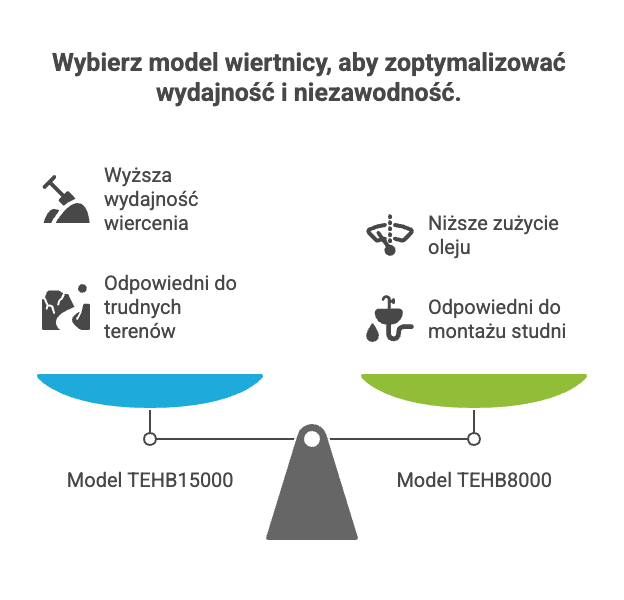

Nothing speaks louder than concrete figures and experiences from the field. One customer in the Mazovia region used the TEHB15000 for a series of pile drillings on difficult, clayey-sandy ground. Working with a 13-tonne backhoe loader, he managed to drill more than 40 boreholes with a depth of 3 metres and a diameter of 600 mm - in one day. This is a speed that he would not have been able to achieve with a classic hand auger or equipment that does not work with a machine.

Another example? A company in the Podlasie region deployed the TEHB8000 to expand its services to include well installation. Mounted on a 9-tonne carrier, the equipment handles wells up to 10 m deep. Operators particularly emphasise the low oil consumption and high reliability - crucial for long operating cycles.

This shows one thing - choosing the right model really does make a difference. Not only in terms of operating speed, but also in terms of energy consumption, operating costs and operator comfort.

Three questions you need to ask before buying a drill rig for your backhoe loader

Before you click 'buy now', pause for a moment. Choosing a hydraulic earth auger for excavator is a decision that will affect the quality of your work for years to come. Ask yourself three key questions.

- Is my machine strong and stable enough to support the model you choose?

If you're not sure - it's better to seek technical advice rather than risk damaging the hydraulic system. - What jobs do I do most often?

Not every drill rig is universal. A different model will work well for installing a fence and another for drilling for electricity poles. - Do I have a realistic chance of recouping my investment?

Ask yourself whether a new drill rig will bring in additional work, speed up current projects or reduce the need to hire external equipment.

If you don't know the answer - it's better to consult the specialists at TechnaPoland. This will help you avoid mistakes that later cost more than the machine itself. And if you already know what you are looking for - check out the range of hydraulic earth augers for construction machinery and find a model that will work from day one.

Read also:

- How to choose the right hydraulic earth auger for mini excavator?

- Drilling rigs for crawler excavators - what should you know before buying?

- Proper operation of hydraulic earth augers

- Types of excavator drilling rigs - which ones to choose for specific tasks and materials?

- When to buy a new or used hydraulic earth auger - how to make the right decision?

- Hydraulic earth auger - when is it worth buying and when is it better to rent?

- Hydraulic earth augers for excavators - what to choose hydraulic, mechanical or pneumatic drive?

- The most common failures and faults of hydraulic earth augers - how to solve them?

- Modern hydraulic earth augers - we present their applications in construction, agriculture and forestry

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous