The cost of repairing a breakdown of a large hydraulic earth auger can be as much as £50,000 - that's the price of a new passenger car or nine months' wages for the operator. Most of these breakdowns can be avoided with proper operation and regular maintenance. A five-minute warm-up of the hydraulic oil, checking the three basic operating parameters or following the rule of breaks every two hours are simple steps that can extend the life of your equipment by 30-50 per cent.

Why can a five-minute warm-up save you tens of thousands of pounds?

Most operators have a habit of doing this - they start the machine and get straight to work. This is one of the most expensive mistakes you can make when operating hydraulic earth augers. Cold hydraulic oil has completely different properties than oil that has reached its optimum operating temperature. It is denser, does not flow freely through the system and does not provide adequate lubrication to all moving parts. When you force a cold system to work immediately under full load, you create conditions for accelerated wear of the hydraulic pump, valves and motors.

This is why it is important, especially in winter, to run the drill without a load and without drilling into the ground. This way, the oil from the cold drill will be pumped into the oil tank of the machine and warm up there.

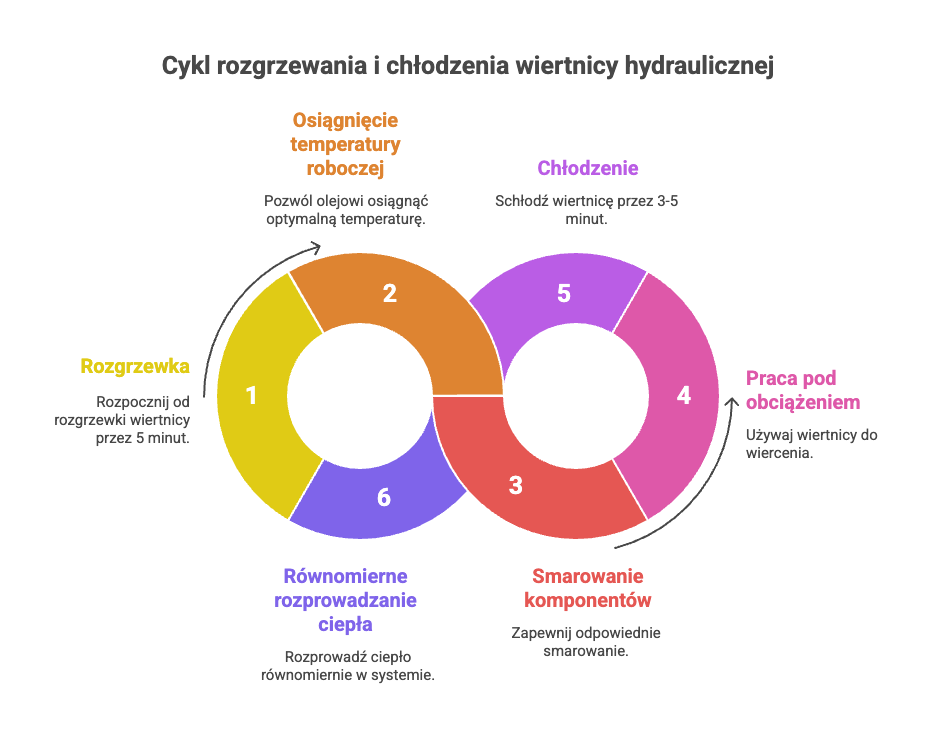

A professional warm-up is not just a few revolutions of the drill rig at idle. It is a deliberate process that should take a minimum of five minutes with a light load. During this time, the hydraulic oil gradually reaches operating temperature, its viscosity decreases and all system components get adequate lubrication. Particularly in winter, when the ambient temperature drops below freezing, this process becomes absolutely critical. Although winter-proof oils have better properties at low temperatures, even they need time to reach optimum performance.

Just as important as the warm-up is the proper cooling of the system after intensive work. Suddenly shutting down the engine after heavy drilling results in spot overheating of the hydraulic nodes - the oil remaining in the confined spaces has no way of circulating and its temperature can rise to critical values. Therefore, continue to drive the drill at idle for 3-5 minutes after any heavy drilling. This will allow the oil to expectorate excess heat and distribute the temperature evenly throughout the system. This simple habit can extend the life of hydraulic earth augers for construction equipment by up to 30-40 per cent.

JCB's professional excavator drills are designed for maximum durability under heavy use. Equally reliable are the hydraulic earth augers for excavators from CAT, whose design guarantees full control of the borehole. In the compact segment, the Kubota mini excavator auger for excavators is worthy of note, while among the lightweight machines, the Bobcat hydraulic earth auger for backhoe loaders stands out.

Three parameters you need to control every day - otherwise your drill rig will stop working

Checking basic operating parameters on a daily basis is the difference between reliable equipment and a costly breakdown. It's not about complicated measurements that require specialised apparatus - just basic observation and a few simple checks that will take you no more than 10 minutes every morning.

- Working pressure is the first and most important parameter you should monitor. Each hydraulic earth auger manufacturer specifies optimum pressure values for their equipment, and exceeding these limits leads to accelerated wear of seals, pressure-reducing valves and the entire hydraulic pump.

- Oil flow is the second critical piece of the puzzle. Inadequate oil flow - too little or too much - directly affects the drill rig's torque and efficiency. When the flow drops below minimum values, the drill rig loses power and the operator instinctively increases pressure, leading to overheating of the entire system. On the other hand, too high a flow rate results in excessive speed, which, with an improperly selected drill bit, can result in its premature destruction. Most modern excavators have built-in flow indicators, but if your machine does not have one, it is worth investing in a portable hydraulic flow meter.

- The temperature of the hydraulic system is the third pillar of safe operation. The 80-90 degrees Celsius limit for hydraulic components is not a suggestion - it is a hard safety limit. If this temperature is exceeded, the oil degrades, its lubricating properties are lost and wear on all moving parts increases exponentially. Especially during the summer heat or when drilling intensively in hard ground, the temperature can rise very quickly.

Modern hydraulic earth augers for backhoe loaders often have built-in temperature sensors with an acoustic warning, but older models require manual monitoring with a contact thermometer or pyrometer.

Excavator wobble = premature death of the drill rig. How do you prepare the ideal work site?

Machine stability is the foundation of any hydraulic earth auger's long-term operation. Unfortunately, all too often I see operators who start drilling on unstable, uneven ground without realising the consequences of doing so. The wobbling of the excavator while drilling generates additional lateral forces that stress the quick couplings, hydraulic lines and the drill body itself in ways it was not designed for. These abnormal loads lead to micro-cracks in the structure, play in bearings and premature wear of seals.

Preparing the work site is more than just levelling the ground. The ground must not only be level, but also load-bearing - soft ground causes the excavator to 'work' while drilling, which affects the precision of the entire process. The ideal site is a paved area with a slope of no more than 5 degrees, with the ability to fully fill the excavator's stabilisers. If you are working on terrain with variable topography, always look for areas where you can position the machine with all four support points at an even level. For tracked excavators, additionally check that the track tension is adequate - loose tracks increase wobble when drilling.

Hydraulic stabilisers are not an optional extra - they are an essential part of safe working. Many modern hydraulic earth augers for excavators require the use of stabilisers for optimum performance. When extending them, remember to distribute the load evenly - one stabiliser leaning harder than the others introduces stresses in the machine structure, which are transmitted throughout the drill rig. Once positioned, check the stability by making test rotations of the drill rig with no load - any vibration or movement of the excavator indicates the need for repositioning.

Winter drilling in minus twenty degrees - when does standard oil fail and what to do instead?

Winter operation of hydraulic earth augers is a real test of the durability of the entire system. When temperatures drop below minus 10 degrees Celsius, standard hydraulic oils start to change their properties significantly. They become thick, harden, and their flow through valves and lines decreases dramatically. In extreme conditions, at minus 20 degrees,classic hydraulic oil can behave like a paste, making it virtually impossible for the drill rig to function normally. It's not just a performance problem - it's a direct threat to the expensive components of the hydraulic pump, which, when trying to pump the thick oil, works with excessive load.

Winterproof oils are not a luxury, but a necessity when working in harsh weather conditions. They differ from standard oils not only in their low-temperature viscosity, but also in their package of anti-wear additives and stabilisers, which protect the hydraulic system from corrosion caused by condensation. Modern cold-resistant oils remain fluid even at minus 30 degrees Celsius, allowing hydraulic earth augers for mini excavators to operate normally even in the harshest conditions. However, changing the oil is not enough - you should also check all seals and hoses, which can become brittle and prone to breakage in cold temperatures.

Before starting winter drilling, it is essential to extend the warm-up time to as much as 15-20 minutes. Cold oil takes much longer to reach its optimum operating temperature, and rushing the process can damage the hydraulic pump or valves. Keep an eye on the pressure gauges during warm-up - if the pressure is significantly higher than under normal conditions, it is a sign that the oil is still too cold for intensive operation. Additionally, it is a good idea to check the oil level more frequently in winter - condensation in the reservoir can cause an apparent increase in oil level, but in fact leads to dilution and deterioration of lubrication properties.

Five deadly sins of the rig operator - check you're not committing them every day

What can go wrong? A lot, actually. What do you mean?

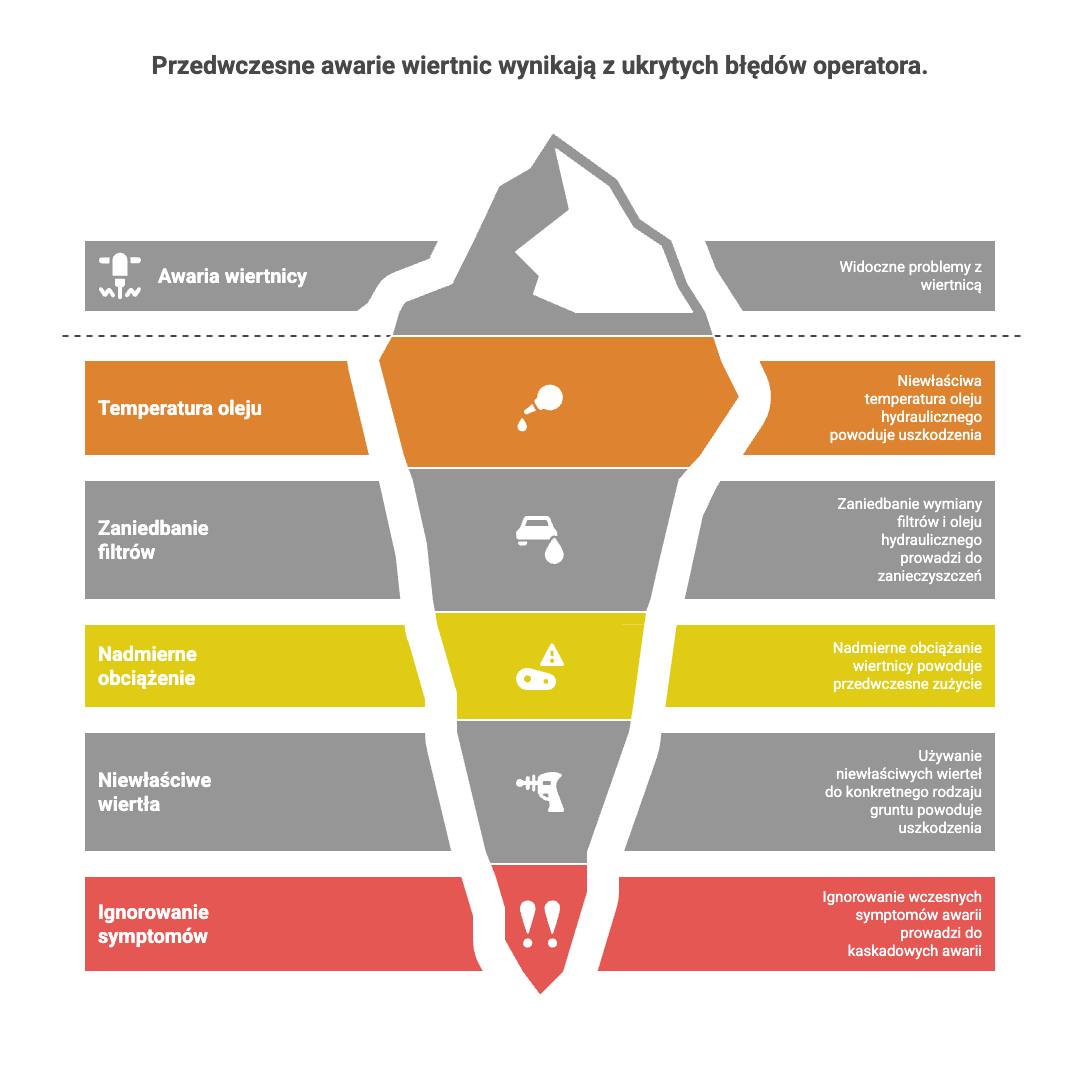

- The first and most common mistake is working with the wrong hydraulic oil temperature. Oil that is too cold, as I have already mentioned, does not provide adequate lubrication, but overheated oil is equally destructive. Once the temperature exceeds 90 degrees Celsius, the oil begins to degrade at the molecular level, losing its lubrication and corrosion prevention properties. Unfortunately, many operators ignore temperature indicators, believing that 'somehow it will work'. This 'somehow' costs an average of £15-20,000 a year in premature repairs to the hydraulic pump and replacement of system components.

- The second sin is neglecting to change filters and hydraulic oil. Contaminated oil is like blood with cholesterol - it may circulate through the system, but it does not perform its function. Microscopic contaminants act like sandpaper on all moving parts, causing accelerated wear. Manufacturers specify change intervals every 500-1000 operating hours for a reason - these figures are the result of precise analyses of oil degradation under real operating conditions. Saving on oil changes is a false economy that leads to repairs costing ten times the amount saved.

- The third mistake is overloading the rig by overly aggressive operating parameters. Many operators think that the faster and harder the better. Meanwhile, every type of soil requires an adjustment in speed and downforce. Drilling too fast in hard ground causes overheating of the drill crown and premature wear of the main bearings. On the other hand, drilling too slowly in soft ground leads to increased drag, putting strain on the entire drive system.

- The fourth is using the wrong drill bits for a particular type of soil - a clay drill bit won't work in stone, while a rock drill crown will wear out too quickly in sand.

- The fifth and final is to ignore early signs of failure - unusual vibrations, noises or changes in the nature of the work. Experienced operators can 'sense' impending problems long before they become fully apparent. Unusual vibrations, a change in operating tone, a drop in torque - these are all warning signals that require an immediate response. Ignoring these symptoms leads to cascading failures, where the failure of one component entails the destruction of subsequent components.

Maintenance schedule five hundred - one thousand - one thousand five hundred - when to replace what and why is this crucial?

A maintenance system based on the number of man-hours worked is the foundation for the long-term operation of hydraulic earth augers. The first major maintenance is at 500 man-hours, which in practice means around 3-4 months of intensive operation. At this point, the first hydraulic oil change takes place, along with the pre-filter and main filter. This may seem early, but new oil always contains microscopic contaminants from the manufacturing process, which are 'washed out' of the system during the first hundreds of operating hours. In addition, new seals and moving parts produce natural wear products that must be removed from the system.

The thousand-hour service is a much more comprehensive procedure. In addition to the standard oil and filter change , the performance of the hydraulic pump, the tightness of the entire system and the condition of the components are checked. This is also the moment to check the tightening torques of all bolted connections - vibrations during operation can lead to their loosening, resulting in thread damage and the need for costly repairs. Experienced service technicians can detect 95 per cent of potential problems at this stage before they develop into major failures.

The 1,500-hour inspection is the most important moment in the life of any hydraulic earth auger. After this period of operation, all weaknesses in design and assembly quality become apparent. A comprehensive service at an authorised centre includes disassembly of major components, dimensional inspection of moving parts and replacement of all seals. It is also the ideal time to upgrade the software of the hydraulic controllers and update the operating maps in accordance with the latest manufacturer recommendations. The cost of such a service can be £8-12,000, but this is still a fraction of the price of a new drill rig, which can cost £80-120,000. A properly performed 1,500-hour service can extend the life of the equipment by another 2,000-2,000 man-hours.

Read also:

- How to choose the right hydraulic earth auger for mini excavator?

- Drilling rigs for crawler excavators - what should you know before buying?

- Hydraulic earth auger for backhoe loader - what to look out for to get the right equipment?

- Types of excavator drilling rigs - which to choose for specific tasks and materials?

- When to buy a new or used hydraulic earth auger - how to make the right decision?

- Hydraulic earth auger - when is it worth buying and when is it better to rent?

- Hydraulic earth augers for excavators - what to choose hydraulic, mechanical or pneumatic drive?

- The most common failures and faults of hydraulic earth augers - how to solve them?

- Modern hydraulic earth augers - we present their applications in construction, agriculture and forestry

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous