In theory, it's just a tool. In practice - one of the most exploited and stressed components of your machine. Hydraulic breakers for excavators work under extreme conditions, often non-stop. And while choosing the right model is the first step, how you use it is equally important. Because even the best hammer, if operated "roughly", will quickly rebel - knocking out sockets, breaking bushings and... costing you money.

In this guide, you will find practical rules for operating a hydraulic breaker that will extend its life in real terms.

Regularly checking clearances and fixings - it's not a small thing, it's your safety and cash in your pocket

At first glance, it may seem that a few millimetres of play is no problem. But when we're talking about hydraulic breakers hammers for excavators, those few millimetres are sometimes the difference between safe operation and failure on site. Loose bolts, handles or working connections can not only affect the precision of work, but can also lead to serious damage to both the hammer and the excavator arm. And such damage can generate repair costs of up to several thousand zlotys. All it takes is for a pin to knock out a socket or for uncontrolled cracking of the housing to occur.

If you work on the machine daily, in service mode or on public works, check all attachments once a week. Replace knocked-out bushings, tighten up clearances. It doesn't take much time, and it makes a significant difference to the life of the hammer and the comfort of your work. If you change operators frequently or use the hammer in difficult terrain - it is even worth doing this daily. Don't leave it "for later". This is one of those tasks that separates professionals from amateurs in practice.

Lubrication is not optional - without it, the hammer will not survive the season.

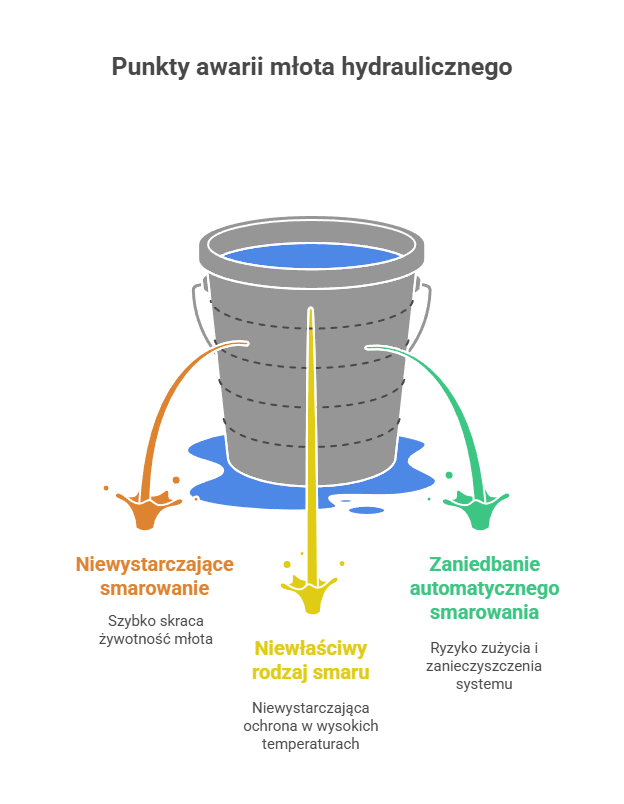

Lack of regular lubrication is one of the most common mistakes that shorten the life of hydraulic breakers hammers for excavators. Wear on the guides, overheating of the chisel or knocking out of the sockets - these are just some of the consequences that await those who neglect this simple duty. And a standard grease gun every few hours of operation would suffice.

Importantly, choose the right grease - not everyone will work well with intense impact and high temperatures. It is best to use high-temperature grease with increased adhesion, dedicated to impact hammers. Models with automatic lubrication, such as many in our range of hydraulic breakers for excavators with demolition breakers for excavators (and more), have an advantage here - but even then it's worth monitoring wear and cleanliness of the system. There is nothing worse than a costly repair due to a seemingly 'innocent' dry bushing.

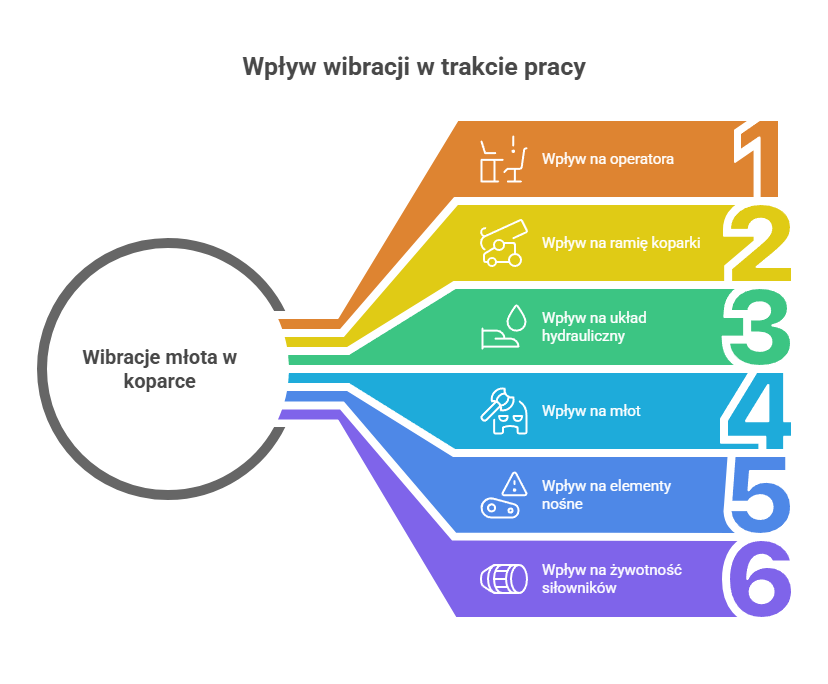

Don't underestimate vibration - the bigger it is, the sooner the whole system will blow up

Too much vibration is not only a problem for the operator and his comfort, but a real threat to the excavator arm, the hydraulic system and the breaker itself. High vibrations are most often indicative of slack, an ill-fitting hammer or inadequate working tools. What's more - they are the fastest to 'eat away' at load-bearing components and shorten the life of the cylinders.

This is why it is so important to select hydraulic breakers for mini excavators and excavators according to the parameters of the machine. A hammer that is too big on a carrier that is too light is a guaranteed problem. Equally important: choosing the right chisel, preferably hardened and suited to the type of soil. Models like the TE 45 or TE 53, equipped with vibration dampening systems, are standard these days - but even the best equipment will not forgive poor settings or worn bushings. Vibration is not a detail. It is an alarm signal.

Work with your head - don't hit when you don't need to

Sometimes the hammer goes 'empty' because the operator simply does not let go of the trigger, even when the tool is not in contact with the ground. Such operation not only drastically reduces piston life, but also introduces unnecessary vibrations and overheats the hydraulic oil. In the long term - this leads to avoidable failures.

Hydraulic breakers for excavators with demolition breakersrequire precision and control. Not every break in operation is a time to 'hammer' into the air. If the tool is unsupported, let it go - give it a rest and save yourself the stress and expense. It's also worth remembering that many models - especially the more powerful ones, like the TE 60 - have their own working speed. The harder the material, the shorter the series of blows and the greater the emphasis on precision, not a forceful approach.

A robust hydraulic breaker for mini excavator from CAT or a breaker for mini excavator from JCB is equipment that any operator will appreciate. Also worth a look are Kubota mini excavator breakers and Bobcat mini excavator breakers - compact but extremely powerful tools for working in hard-to-reach areas.

Seasonal maintenance is not a bureaucracy - it's an investment that pays off

Every hammer, regardless of the brand, needs a full maintenance check-up once in a while. And it's not just a 'glance', but an actual check of seals, valves, oil pressure, piston and housing condition. In practice, it is during the seasonal inspection that problems are detected that are not yet showing symptoms, but are just around the corner.

If this procedure is neglected, you could end up with a costly overhaul or even replacement of the entire hydraulic breakers for excavators. Therefore, if you are working on a continuous basis - plan a break, schedule a service. Availability of spare parts, technical support and fast diagnostics is what sets good suppliers apart. And it's worth taking advantage of this before more serious problems arise.

Looking for a hammer that won't let you down at the first hard blow?

At TechnaPoland you'll find proven hydraulic breakers for excavators, crawler excavators, mini excavators, and backhoe loaders - only from reliable sources, with real technical support and parts for backhoe loaders available now. Check out our range and choose equipment that's not afraid of the job. Give us a call or write - we'll match the hammer to your machine.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- The wrong hammer is a big problem. How do you choose the right model for your excavator?

- How does a hydraulic breaker work?

- Hydraulic breakers for excavators with demolition breaker - what to look for when choosing one?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hydraulic breaker versus pneumatic breakers for excavators - differences, disadvantages, applications

- Hammer or hydraulic hammer breaker - which will work better on your excavator?

- Don't choose blindly - find out the real differences between hammer and vibratory hammer

- Hydraulic hammer lubrication - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous