At first glance, the choice between a hammer and a demolition shear may seem simple - after all, both tools are designed to destroy hard materials. But the difference lies in the details: the design, the force, the type of work and the ... side effects. One tool is better suited to demolishing masonry with the force of a blow, the other for precision cutting of steel or reinforced concrete structures.

In this article, we explain when cutting shears are the better choice and when it is better to go for a hydraulic hammer. On top of this, we compare the key parameters and give tips on how to choose equipment for an excavator.

Demolition shear or demolition hammer - what are the key differences?

There are a variety of solutions available on the market to facilitate demolition - from classic demolition breakers for excavators to more precise cutting shears for excavators. Both tools work on a different principle and perform in different conditions, so it is worth knowing their key differences before choosing an attachment. What's worth knowing? We already say.

Hydraulic hammer - power through impact

Demolition breakers for mini excavators and excavators work on the principle of high-frequency impacts with kinetic energy. They are ideal for:

- breaking concrete,

- crushing pavement,

- forging in rock,

- wall and foundation demolition.

It's a "get in and smash everything" type tool.

Demolition shears - precision through cutting

A concrete crusher or cutting & crushing shear is a hydraulic tool that clamps down on the material with enormous force, cutting it mechanically. They prove their worth when:

- cutting steel components,

- dismantling reinforced concrete,

- cutting trusses and beams,

- precise demolition without strong vibrations.

Ideal where control, silence and safety are important.

When is it better to rely on shears?

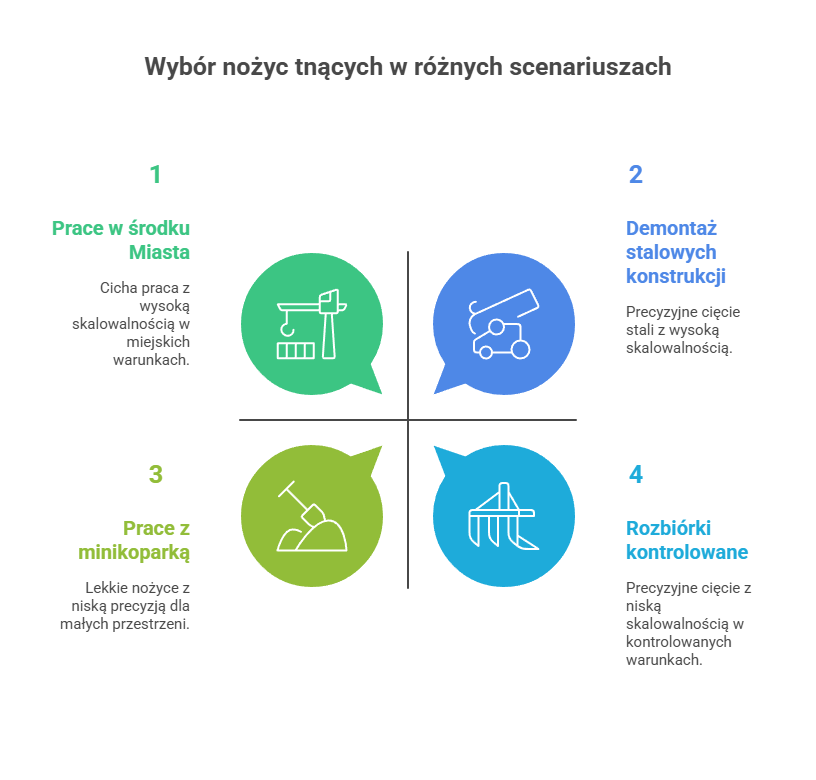

Choosing the right attachment is never obvious. It all depends on where you are working and the effect you want to achieve. In many situations, it is the shears that prove to be unbeatable - where you need a quiet environment, precision or to work in difficult conditions.

Working in the middle of the city

Noise and vibration are the most important factors here - and these simply cannot be avoided with a hammer. The shear works much quieter, so if you are carrying out work near flats, a hospital or a school, the people around you will feel the difference. It's a tool that allows you to work without the constant stress that someone is about to call with a complaint about construction that is too noisy.

Dismantling steel structures

Anyone who has tried to crush steel with a hammer knows that it is a battle with windmills - instead of results, there is only bouncing and wasted time. The shears simply cut through the component as if it were a piece of paper. The CTHB-S50M gives a force of as much as 107 tonnes and a jaw opening of 336 mm, so it can handle massive steel without any problems. Importantly, there is no need to play around with torches or hand cutting - it is faster and, above all, safer.

Controlled demolition

Sometimes it is necessary to act gently - to cut off one beam and leave the rest of the structure intact. A hammer will not work here, as it generates vibrations and always carries the risk of accidental damage. The shears give you full control - you cut exactly what you need to, without any additional surprises. This is a huge plus on industrial sites, for example, where part of the building is still functioning and you are only dismantling a section.

Working with a mini excavator

You're not always working with a heavy excavator on a large site. Sometimes it's a small plot of land, limited space and a mini excavator. And here's the good news - Techna has the CTHB-S17 shear, which weighs just 210 kg and fits machines from 1.7 tonnes. So even a small team with light equipment can get into more demanding jobs without having to hire a large excavator.

And when would a demolition hammer be better?

You don't always need to work with precision - sometimes you just need to go in and knock things down, quickly and efficiently. At such times, the hydraulic hammer shows what it can do.

Massive concrete and asphalt crushing

It is second to none when it comes to destroying large areas quickly. Wherever a concrete slab needs to be broken up, asphalt needs to be chipped or hard rock needs to be penetrated - the breaker is the operator's best friend. It is particularly well suited to roadworks, site preparation for new developments or classic demolition work, where precision is not important, only speed.

High-frequency work with plenty of power.

There are tasks where light equipment simply doesn't stand a chance. If you are dealing with really hard material, you need a tool with powerful impact energy. An example? The Model 210 hammer - weighing over 6.5 tonnes, mounted on 60-80 tonne excavators. It's a piece of equipment designed for heavy industry, mining, large infrastructure structures. Where other tools give up, it just rocks.

Cutter or demolition shear? Technical comparison - power, parameters, compatibility

|

Parameter |

CTHB-S50M (shear) |

Hammer 85 (hydraulic) |

|

Cutting/striking force |

107 tonnes (cutting) |

no precise value - force dependent on impact |

|

Weight |

500 kg |

729 kg |

|

Operating pressure |

230 kg/cm² |

130-160 kg/cm² |

|

Compatibility |

excavators 5-9 tonnes |

excavators 7-14 tonnes |

|

Type of work |

precision cutting |

high-frequency cutting |

|

Noise / vibration |

low level |

high level |

|

Risk of damaging the environment |

low |

high (vibration, chipping) |

|

Operator safety |

higher with respect to the rules |

requires vibration protection |

Demolition shear or demolition hammer? Safety first!

It doesn't matter whether you are working with a hammer or a shear - both tools exert enormous force and require full responsibility on the part of the operator. A mistake, poor maintenance or disregard for health and safety rules can end in a serious accident.

Operating demolition shears requires specific safety rules:

- always use guards between the operator and the tool,

- do not work under loads or leave them hanging,

avoid working close to power lines, - wear personal protection equipment (glasses, gloves, protective clothing),

- use original Techna parts - it's a question of durability and safety.

The shears work with tremendous force - damage to the hydraulics, poor assembly or breakage of the work piece can end tragically. Therefore, regular maintenance, inspections and taking precautions are an absolute must.

What to bear in mind with demolition hammers?

The hammer generates powerful vibrations, so here the most important thing is to:

- regularly check the condition of the hammerhead and the attachment,

- keep an eye on the tightening torque, because play on the bolt is a quick way to damage it,

- pay attention to hydraulic lines and couplings - vibrations can weaken them rapidly,

- protect the operator's cab from splinters,

- use the hammer in accordance with the recommended machine class - an excavator with demolition breaker that is too light risks tipping over or causing excessive wear to components.

Remember - no matter what attachment you are working with, operator safety and machine longevity depend on how you look after the equipment. Regular maintenance, genuine parts and good habits are not an option - they are an obligation.

Bottom line: what to choose? A cutting shear or a demolition shear hammer?

|

Do you need... |

Choose |

|

Quickly break concrete or asphalt |

Hammer |

|

Quiet work in an urban environment |

Shears |

|

Cut through steel construction |

Shears |

|

Working in confined spaces (mini excavator) |

Shears |

|

Working at great depth or in the ground |

Hammer |

|

Controlled cutting of reinforced concrete |

Shears |

|

Crushing of massive structures |

Hammer |

Finally, a practical tip

There is no one 'one size fits all' attachment. If you're dealing with different types of demolition - it's worth considering both a hammer and shears in an attachment set. That way you always have a tool to match the task.

Want to choose a Techna shear for your excavator? In doubt about which model will work better for you? Contact us - we will advise you, compare the parameters and help you find the ideal solution.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous