Choosing concrete pulverizers for excavators is about more than just comparing crushing force and price. If you want real performance, low running costs and equipment that won't let you down at the worst time - you need to pay attention to things that you don't always see at first glance. The right weight, geometry, mounting method or quality of chisels are details that make a gigantic difference in practice. Read on to see how to choose concrete pulverizers for excavators that actually fit your excavator and type of work.

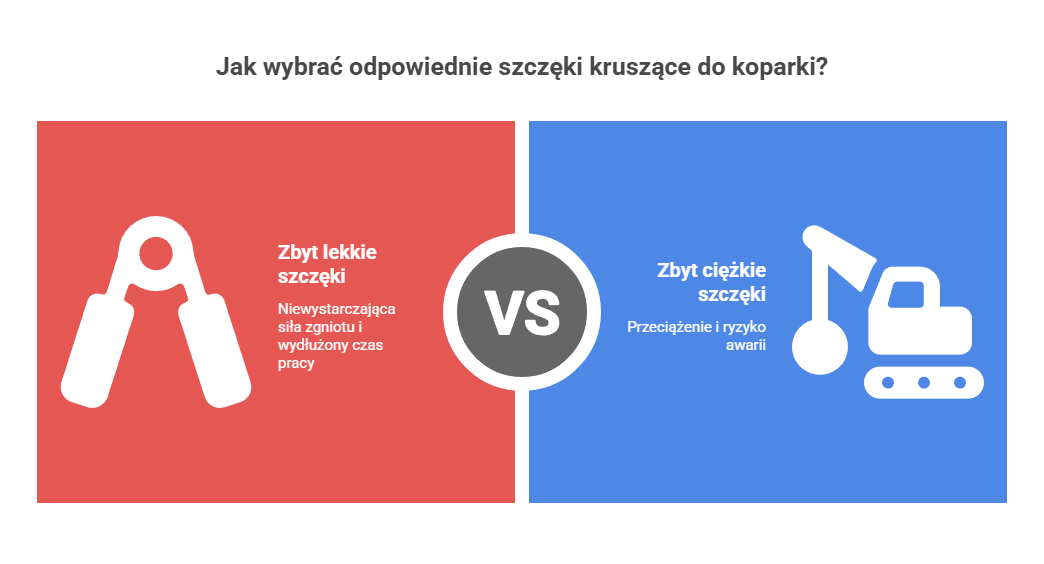

Weight and strength of concrete pulverizer for excavator - why not choose 'by eye'?

Choosing concrete pulverizer for excavator is more than just matching the size of the tool to your machine. Jaws that are too light will not provide adequate crushing force, those that are too heavy will overload the structure and hydraulics of the arm. That's why it's important that the weight of the attachment is matched not only to the tonnage of the excavator, but also to its operating parameters. For example, models for excavators from 14 to 20 tonnes usually operate with jaw weights between 1000-1500 kg, but for machines over 25 tonnes, attachments that exceed 2000 kg are chosen.

Crushing force is the second element that directly affects the efficiency of the work. If your jaws do not reach the right pressure - e.g. 100-150 tonnes for typical demolition work - the crushing time will increase significantly and the process will become costly and inefficient. Therefore, when making a decision, it is always worth checking the maximum pressure and comparing it with the requirements of the specific job. Well-chosen jaws not only mean faster work rates, but also less risk of breakdowns and costly downtime.

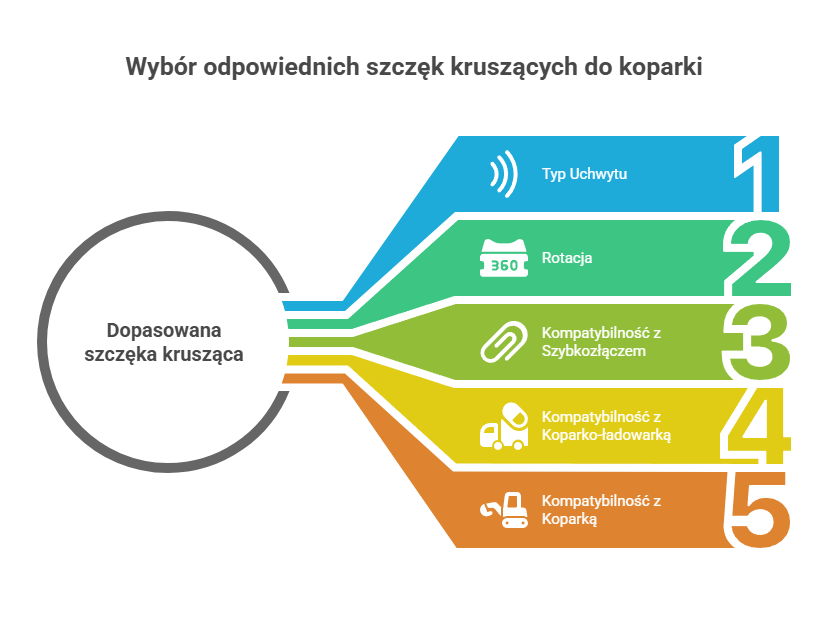

Handle, mounting and rotation - how not to miss the mark when choosing the right concrete pulverizer for excavator and gain the freedom to work?

At the selection stage, it is easy to overlook elements such as handle type, rotation or the ability to work with a quick coupler, and it is these that directly affect the daily comfort and productivity of the operator. Particularly important is the hydraulic rotation - a full 360° of rotation that allows the jaws to be accurately positioned in any position without having to manoeuvre the entire machine. This is crucial, especially when working against walls or in tight spaces.

It's also worth making sure that the handle of a particular model will be compatible with the arm of the excavator or backhoe loader you plan to work with. Not all jaws have a quick coupler from the factory - and not having one can mean extra costs for fitting or hydraulic modifications. That's why it's important to check all the technical details, including sling type and working pressure range, at the buying stage.

If you work on backhoe loaders, reach for parts for excavator loaders that include matching jaws, quick couplers and adapters. For users of classic excavators, on the other hand, the TechnaPoland website has a dedicated range of parts for excavators, where you can easily select components with specific manufacturers' models in mind.

Shape and geometry of the jaws - more than aesthetics, or what translates into efficiency?

It's not just about how the jaws look - it's about how they work. The working shape of the crushing jaws affects how they break material, how deeply they bite into it and whether they cause unnecessary energy loss. You will choose different jaws for pure concrete, others for reinforced concrete and still others for asphalt and brick. If the tool is not well matched to the material - it can not only slow down the work, but also wear out much faster.

Many modern models use an optimised jaw geometry, so that it is easier to hold the material in place during crushing, and the breaking moment itself occurs more quickly. This means less energy consumption, lower loads and greater operator comfort.

Remember that different geometries mean different angles of attack, jaw lengths and ways of distributing forces. It is not worth going for 'one-size-fits-all' solutions here - these will work, but only for very general jobs. If you have a clearly defined task - such as crushing reinforced concrete pillars - it is better to go for a model that has been designed for such work. Then you gain not only productivity, but also greater safety and operational stability.

Chisels and blades - do material and installation matter?

You can invest in great jaws and still have a performance problem if the blades are made of low-quality steel or have a bad angle of attack. Working chisels should not only be hardened, but should also be resistant to cracking and micro-splinting. In practice, this means using tool steel with high wear resistance, preferably with chromium and vanadium additives.

Pay attention to whether the jaws incorporate a system for easy replacement of the blades, without having to dismantle the entire body. This reduces servicing time in real terms and, with intensive use, makes a huge difference. Especially in situations where you need to switch from concrete to brick or vice versa and this requires a change of blade type.

The concrete pulverizer for excavators range at TechnaPoland includes models that use segmented, interchangeable working edges. This not only allows you to carry out servicing more quickly, but also to match the working tools to the specific task. This is a huge advantage if you work in a variety of conditions and don't want to waste time with inefficient work.

When is it worth investing in premium jaws and when will basic ones suffice?

Not every investment has to immediately mean buying the most expensive equipment in the catalogue. Premium jaws make sense if you plan on intensive, daily use on large construction sites and with demanding materials such as reinforced concrete, foundations, steel components or precast. In this case - a more expensive model will pay for itself more quickly, as it will provide higher productivity and a lower risk of failure.

On the other hand, if your jobs are more ad-hoc - such as crushing brick after demolishing partition walls once every few weeks - a basic model will suffice, but with good access to parts and service. That's important, because even the simplest attachment can be cost-effective if it's solidly built and well-matched to the excavator. And this is where the key comes in - the choice must always take into account your real needs, not just the 'optimum parameters from the catalogue'.

If you are just getting into the subject - get in touch with TechnaPoland's advisors. We will help you match the jaws to your specific machine and task - whether it's for large excavators or parts for mini excavators. A well-chosen attachment is not just an investment in a tool - it's an investment in peace of mind on the job.

Or do you want to find the perfect jaws for your excavator and type of work? Check out our range of concrete pulverizer for excavators and get help from TechnaPoland's advisors. We help you select equipment that realistically works for your results.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous