Demolition is an integral part of any major construction project. Whether it is demolishing an old building, destroying a road surface or breaking up reinforced concrete elements, it is crucial to choose the right equipment. The two most common solutions are hydraulic demolition breakers and demolition jaws. Although the two tools have a lot in common, their application and effectiveness in specific tasks differ significantly. Which solution is better? Let's find out.

What is a hydraulic breaker and how does it work?

The hydraulic breaker is one of the most popular demolition tools. It works on the percussion principle - hydraulic energy is converted into an impact force that crushes materials such as concrete, asphalt or stone. Hammers are mounted to the arm of an excavator, mini-excavator or loader.

Advantages of the hydraulic hammer:

- versatility - suitable for both light and heavy work,

- precise point work,

- ability to work in confined spaces,

- availability of models for every class of machine - from 1.5 to 30 tonnes.

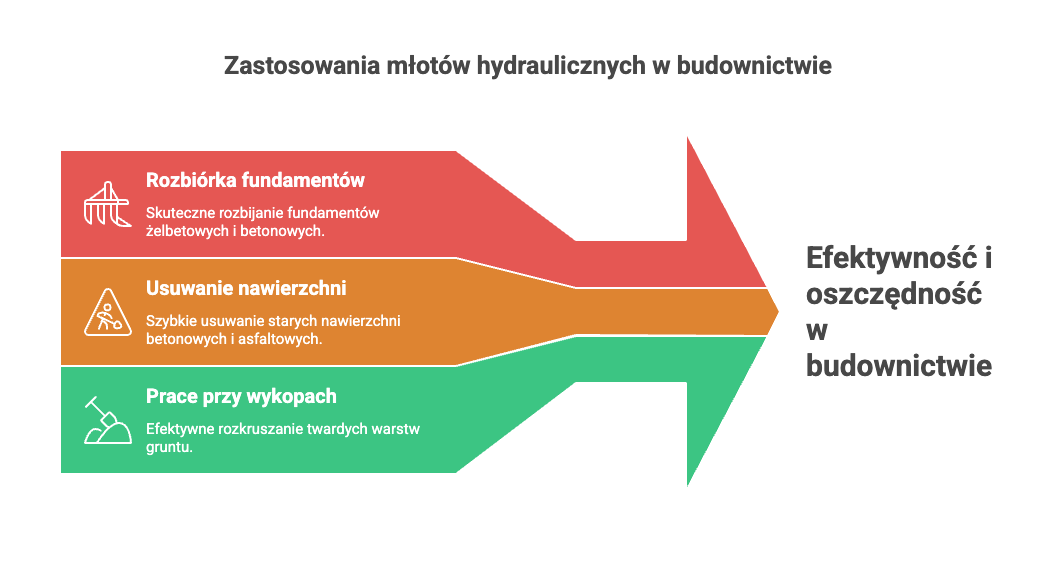

Hydraulic demolition breakers - what can they be used for?

- Breaking out foundations

Hydraulic demolition breakers for mini excavators and excavators are ideal for demolishing old reinforced concrete or concrete foundations. Thanks to their high percussion energy, they are able to effectively demolish even massive and deeply embedded structures. This is a key tool when extending, upgrading or completely removing industrial and residential buildings. A well-chosen hammer (e.g. with an impact force of 800-1500 J) speeds up the work and significantly reduces the cost of dismantling foundations.

- Breaking concrete and asphalt surfaces

Hydraulic hammers are indispensable on construction sites and in road construction projects for removing old pavements. Amongst other things, they are used for demolishing old concrete slabs, breaking up kerbs, pavements or infrastructural elements of manoeuvring and industrial sites. Compared to manual methods, the hydraulic hammer mounted on a mini-excavator or loader can quickly clear the site for further work - laying a new road, sewer or foundation.

- Linear excavation work

When excavating for pipes, cables or underground utilities, the hydraulic breaker can quickly break up hard ground frozen in winter. Its use in linear excavations eliminates the need for specialised cutters or dynamite. It is particularly useful in city centres where explosive methods or heavy equipment cannot be used.

What are demolition jaws?

Demolition jaws for excavators are attachments that combine cutting and crushing functions. They resemble massive pincers fitted with teeth and cutting blades. Depending on the model, they can be equipped with mechanical or hydraulic rotation, which increases their precision and working range.

Advantages of demolition jaws:

- Simultaneous cutting and crushing,

- ideal for reinforced concrete - cuts through steel and crushes concrete,

- Quiet operation compared to hammers,

- possibility to recycle material on site.

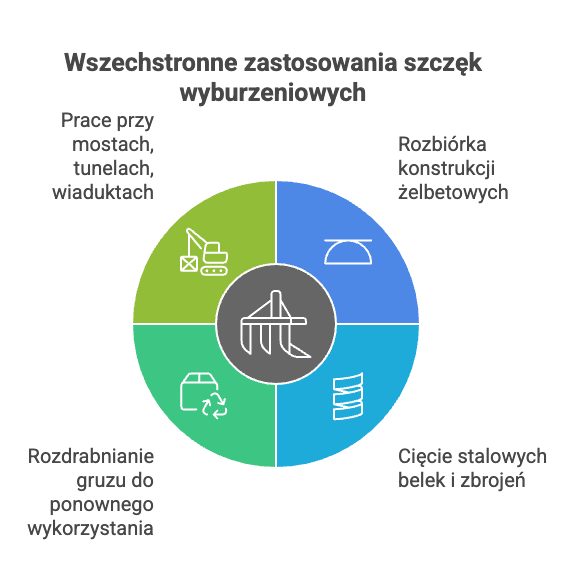

Examples of demolition jaws applications - see where they work best

- Demolition of reinforced concrete structures

Demolition jaws are an essential tool when demolishing massive reinforced concrete elements - foundations, floors, columns and load-bearing walls. Thanks to their enormous crushing force (up to 300 tonnes), the jaws are able to crush hard concrete and cut through embedded steel reinforcement without the use of additional tools. They are particularly suitable for the demolition of industrial buildings, transformer stations and technical infrastructures.

- Cutting steel beams and rebar

Modern models of demolition jaws are equipped with blades with high cutting force to cut through steel beams, HEB profiles, trusses and dense rebar. This eliminates the need for oxygen torches or angle grinders. Cutting is quick and precise, resulting in reduced working time and improved safety. It is ideal for dismantling steel halls, loading ramps or cranes.

- Crushing of rubble for re-use

The crushing jaws allow rubble to be efficiently processed on site. This reduces waste and the costs associated with transport and disposal. The crushed material can be used as ballast, trench fill or a construction layer for a temporary road. They are particularly appreciated in areas with limited access to aggregates or for projects implemented according to circular economy principles.

- Work on bridges, tunnels, viaducts

When demolishing infrastructure elements such as bridges, tunnels, viaducts or flyovers, demolition jaws provide high precision and control over the crushing process. They allow the structure to be demolished in stages without the risk of damaging neighbouring elements or underground infrastructure. Their use is also invaluable in areas where the use of explosives or heavy equipment is not possible for safety reasons.

Hydraulic breaker or demolition jaws for excavators? A comparison of attachments in terms of application, cost, operation and more

|

Criterion |

Hydraulic breaker |

Demolition jaws |

|

Application |

Spot work - demolition of foundations, concrete and asphalt pavements, crushing of hard ground layers, rescue operations. |

Demolition of reinforced concrete, cutting of steel and beams, crushing of concrete with reinforcement, crushing of rubble on site, dismantling of bridges and infrastructure structures. |

|

Purchase costs |

Typically lower, large availability of models for different classes of machinery. |

Higher - investment in heavier, more sophisticated attachments. |

|

Operating costs |

Greater wear on excavator arm pins, faster wear of working parts (e.g. spearheads). |

Lower fuel consumption, longer tool life, lower wear on excavator arm pins. |

|

Service costs |

Service relatively simple, but more frequent due to intense vibration and wear. |

Simple service + less frequent intervention. |

|

Performance |

Very effective for spot crushing, but slower for large structures. |

High performance in large demolitions, ability to cut and crush simultaneously. |

|

Impact on the environment |

Noisy operation, high noise and vibration levels, moderate dust. |

Significantly quieter compared to hammers, less vibration, possibility of dust reduction due to on-site recycling. |

|

Requirements for a construction machine |

Can even be mounted on mini-excavators from 1.5 t, does not require high hydraulic power. |

Requires larger machines (from 6-11 t upwards), higher hydraulic flow and carrier stability. |

|

Compatibility with equipment |

Very wide - from mini-excavators to 30 t excavators. |

Limited - mainly medium and heavy excavators, compatibility dependent on tonnage and hydraulic system. |

Demolition jaws and demolition hammers available at Techna Poland - bet on proven equipment.

Techna Poland offers both hydraulic demolition breakers for excavators as well as demolition jaws for machines of different tonnages.

Popular demolition hammer models:

- TEHB2000 - for mini excavators 1.5-3 t,

- TEHB6000 - for backhoe loaders 4-6 t,

- TEHB15000 - for 10-15t excavators.

Demolition jaws:

- HRP400 - for 6-11 t machines (light work),

- HRP600 - for 12-17 t machines (medium size demolitions),

- HRP1000 - for 27-38 t machines (heavy industrial work).

Crushing jaws or hydraulic breakers hammers for excavators - a summary of the knowledge gathered. Which to choose?

Demolition requires the attachments to be matched to the scale and nature of the work. Both demolition jaws and a hydraulic demolition breaker have their strengths - the choice depends on site conditions and the developer's priorities.

When is it better to choose demolition jaws?

Jaws will work well where efficiency, fast work rates and the ability to crush and cut material at the same time are important. They are the best solution when demolishing reinforced concrete, large industrial buildings or structures with steel reinforcement. They also make it possible to process debris on site, which reduces transport costs and promotes the circular economy.

When is it better to choose a hydraulic breaker?

A hammer will be suitable if you need a versatile and less expensive tool that can cope with a variety of conditions. It will work best for spot jobs such as breaking foundations, removing concrete or asphalt surfaces, as well as on smaller construction sites and in confined spaces. It is a good choice for companies looking for an attachment with a wide range of uses and simple operation.

Do you have questions or want to select the right model? Contact our Techna expert - we will select a solution tailored to your machine and needs.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous