The hydraulic grapple looks inconspicuous, but it is one of the most versatile attachments for excavators you can attach to your excavator. It works well for demolition, grading, forestry work and even recycling or transporting logs. And while its operation may seem simple on the surface, behind every movement of the jaws is a precision hydraulic system, specific technical specifications and a well thought-out design that leaves no room for chance. In this article, you will learn the full principle of a hydraulic gripper - from the construction, to the control, to the selection of the attachment for a particular machine.

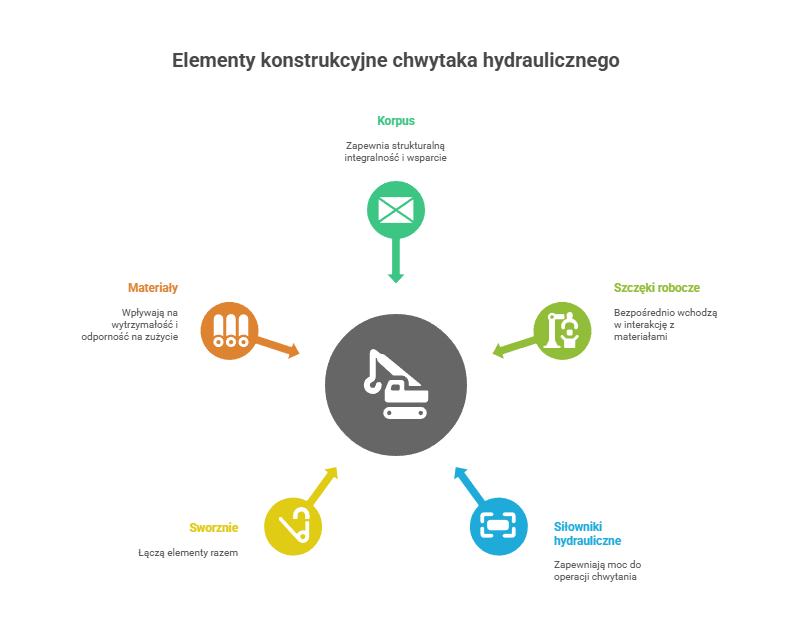

What components make up the design of a hydraulic gripper - what really matters?

Although hydraulic grippers may look quite similar from the outside, their internal construction and the materials used make a huge difference to how they will perform in day-to-day operations. The body, the working jaws, the hydraulic cylinders and the pins that connect all the components together are key. But it's not just about whether they are - what they are made of and how they are designed is important.

Good models use higher strength steel, often with extra reinforcements in the most vulnerable areas. Pay particular attention to the working jaws - these are the ones that come into contact with the heaviest material, so replaceable teeth, hardened cutting edges or special protective inserts should be standard here. It's also worth checking how the hydraulic system is designed - compact cylinders with well-protected hoses mean fewer breakdowns and better performance.

You don't have to guess which models meet these requirements - TechnaPoland offers proven hydraulic grapples for excavators that focus on durability, functionality and easy service. If you work on a 6-9 tonne machine, check out the TE-SG6-9 demolition grapple - an example of a sensibly designed attachment for everyday, demanding tasks.

What makes a hydraulic grapple for excavators work at full power?

The performance of a hydraulic grapple doesn't just depend on its appearance or weight - the real differences start when the attachment gets to work and starts to work with the excavator's hydraulic system. The most important thing here is whether the parameters of the attachment have been matched to the pressure and flow of your machine. And it's not just about making it 'work', it's about making it work efficiently, without lagging, jerking or overloading.

If the excavator is not delivering the right flow, the grapple may run late or not close all the way. In turn, too much pressure can lead to damage to seals, actuators or structural cracks. This is why it is important to always check the technical requirements of the attachment and compare them with the capabilities of the excavator. At TechnaPoland, the selection of attachments is always done with full specification in mind - not only the weight, but also the hydraulic characteristics.

If you're operating on a machine in the 12-17 tonne class, it's worth looking into a solution such as the hydraulic grapple for excavator grapples for excavators. This model not only works with typical hydraulic systems, but also offers a robust design that is not afraid of prolonged operation under heavy loads.

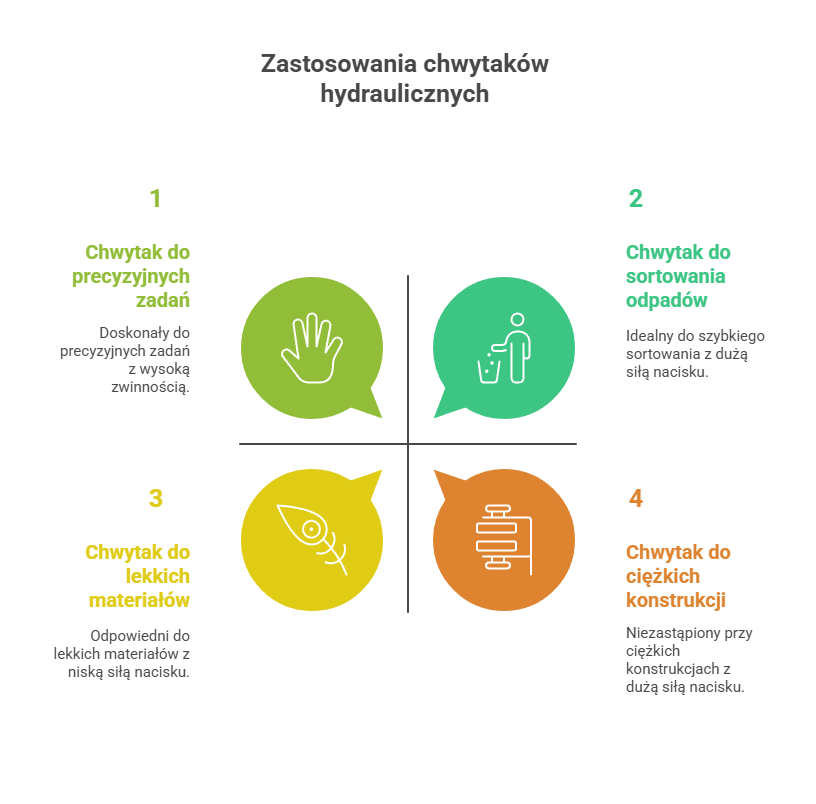

What applications do hydraulic grapples have and what determines their effectiveness?

Although hydraulic grapples are primarily associated with demolition, their applications are much broader. Unloading scrap metal, sorting construction waste, moving large structural components, working in recycling - these are just a few examples. However, each of these tasks requires slightly different working characteristics, so choosing the right gripper type is crucial.

For concrete and structural work, choose models with reinforced jaws and a large clamping force range. For more precise tasks, where you need to sort or select material quickly, more agile, lightweight and dynamic grippers are better. And don't forget to check the mounting options - a 360° rotator or limited range of movement can make a big difference to your working comfort.

If you're using such a machine, be sure to check out parts for excavator loaders that will streamline attachment installation and configuration for your specific needs.

Why invest in quality - not just performance?

At first glance, hydraulic grapples differ mainly in terms of weight and jaw reach. But if you take a closer look, you will notice that the biggest difference is in the construction details, the quality of the welds, the way the cylinders are secured, as well as how the service and availability of spare parts is handled. A fixture that looks good on paper may turn out to be problematic after a few months of operation - because the manufacturer has not provided adequate reinforcements or has used low-quality materials.

Therefore, it is not worth making compromises - especially if the machine is working in intensive or harsh environments. Better material means longer jaw life, fewer failures and fewer interruptions. With TechnaPoland, you also have the reassurance that there is a team behind the equipment that knows its stuff - and who will help you match the gripper not only to the parameters of the machine, but also to the specific application.

If you want to select a hydraulic grapple for excavators or backhoe loaders in a thoughtful way - check out TechnaPoland's full range. All models are ready to go and our team of specialists will help you choose the best solution for your needs and equipment capabilities. A well-chosen grapple is not only better performance - it's also peace of mind and a greater return on investment.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous