Choosing the right hydraulic breaker for excavators with demolition breaker for backhoe loaders is a decision that affects not only the speed and quality of the work being carried out, but also the operating costs and safety of the entire set-up. An ill-fitting model can overload the machine, shorten its life or simply fail to cope with a demanding task. In this guide, we show you what to look for when buying a breaker to ensure it lasts a long time, works efficiently and is fully compatible with your excavator with demolition breaker. In addition, you'll learn about proven models from TechnaPoland's industry-recognised range.

How to match a hydraulic breaker for excavator with demolition breaker for backhoe loaders to avoid overloading the machine and to maintain full power?

Choosing a hammer for excavators with demolition breaker for backhoe loaders is not just a question of price or brand - the technical specifications are key and must match the capabilities of your machine.

- The most important thing is to match the operating pressure and oil flow to what the hydraulic system offers. If the breaker demands more than the excavator with demolition breaker can deliver, the blows will become weaker and the work less effective. An oversized model, on the other hand, can lead to overloaded hydraulics and accelerated component wear.

- It is equally important that the power and frequency of impacts are matched to the type of job being performed. For lighter municipal work, a moderate-energy hammer will suffice, but for demolition of reinforced concrete or foundation work, a more powerful model will be necessary. A well-chosen hammer will not only increase the speed of the job, but will also extend the life of the machine.

If you have any doubts, it's worth getting help from specialists - at TechnaPoland you will find both advice and a wide selection of hydraulic breakers for excavators with demolition breaker for backhoe loaders that are proven in practice and matched to different makes and models of machines.

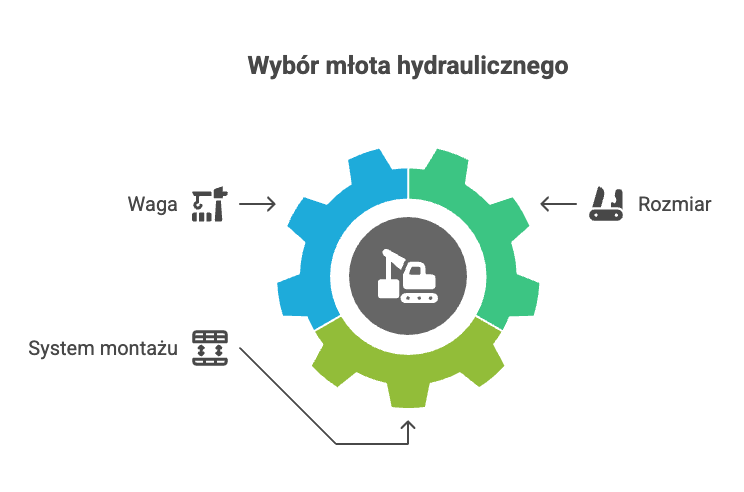

Weight, size and mounting system - three elements that will determine the comfort and safety of your work

The weight of a hydraulic breaker is one of those parameters that is still sometimes underestimated, but in practice has a huge impact on safety and comfort. A model that is too heavy can not only interfere with the stability of the backhoe loader, but also cause difficulties in manoeuvring, especially on uneven ground. This, in turn, increases the risk of damage to the undercarriage or working arm components. In extreme cases, overloading can lead to hydraulic system failure or accelerated tyre and suspension wear. Therefore, when choosing equipment, it is worth checking the load capacity of the machine carefully and taking into account the type of ground you will be working on - there are different requirements for working on a paved construction site and others in soft, clayey ground.

The size of the hammer also matters. A model that is too large may limit your room for manoeuvre in narrow spaces, making it difficult to work against walls, pillars or near underground utilities. On the other hand, a hammer that is too small will be less effective, which can increase the time it takes to complete tasks and increase operating costs. This is why it is so important to find the optimum balance between performance and mobility - the equipment should be strong enough to cope with the toughest material, but agile enough to allow work in hard-to-reach places.

Equally important is the mounting system, which should be fully compatible with your backhoe loader. You can choose from standard mounts, quick couplers or dedicated adaptors, among others. Each solution has its advantages - a quick coupler allows you to swap attachments in the field in an instant, while a dedicated adapter guarantees a perfect fit and minimises the risk of backlash during operation. Choosing the right mounting system can significantly reduce set-up time and improve the ergonomics of daily hydraulic hammer operation.

In TechnaPoland's offer you will find hydraulic breakers for excavators, hydraulic breakers for mini excavators or breakers for crawler excavators, which offer different mounting systems and weights to match the type of work. This will ensure that you choose a model that is not only powerful, but also comfortable and safe for everyday use.

Impact power, pressure and oil flow - how to read the technical parameters to choose well?

Impact power and energy are the first parameters to look at when analysing the specifications of a hydraulic breaker. They largely determine whether the equipment can cope with hard concrete, compact rock or a thick layer of asphalt. An underpowered hammer will cause work to drag on, increasing fuel consumption and labour costs. Conversely, an oversized hammer can generate unnecessary loads that will accelerate wear on the excavator's structural components and even lead to costly breakdowns. Choosing the right power level should therefore take into account both the type of material and the frequency of the planned work.

Another key aspect is the operating pressure, given in bar, and the oil flow, expressed in litres per minute. These two parameters must be fully compatible with the capacity of the machine's hydraulic system. Exceeding the maximum values can lead to damage to pumps, hoses or valves, while values that are too low can lead to a loss of efficiency and a decrease in impact force. Therefore, it is necessary to check the data in the documentation of the excavator with demolition breaker excavator and compare it with the requirements of the manufacturer of the breaker before purchasing.

Also not to be overlooked is the diameter of the working blade, which has a direct impact on how energy is transferred to the material. A larger diameter allows the force to be distributed more evenly, which is beneficial when crushing larger pieces, while a smaller diameter makes it easier to break hard structures in spots. In practice, this means that by selecting a breaker to suit your needs, you can significantly increase the efficiency of your work and reduce wear and tear on components.

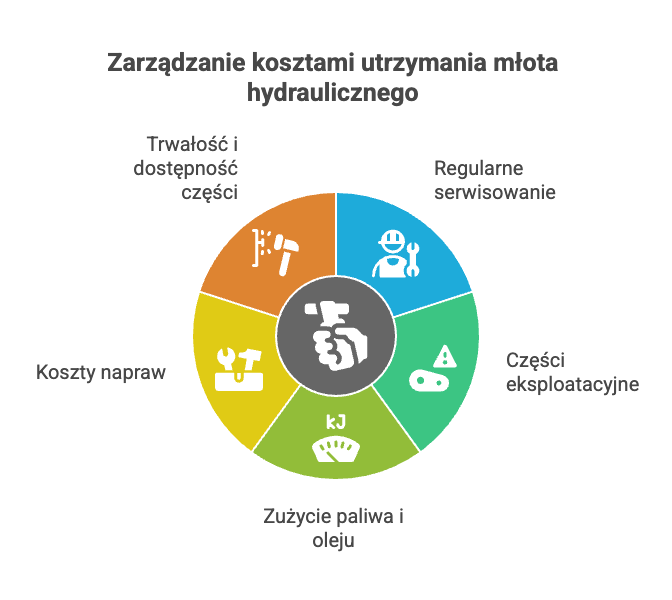

Running costs of a hydraulic breaker - what to budget for to avoid surprises

Buying a hydraulic breaker is one thing, but equally important are the costs of keeping it in full working order. Fixed expenses include regular servicing - replacing seals, checking the hydraulic system, lubrication and maintenance. Then there are consumable parts, such as the spearhead or guide bushings, which may need to be replaced more often depending on the intensity of the work.

The cost of fuel and hydraulic oil consumption is also worth considering - working with a hammer increases the machine's demand for these utilities, especially for long, intensive tasks. Added to this is the possible cost of repairs in the event of failure due to overloading or improper operation.

To optimise these expenses, choose models with high durability and easy access to spare parts.

When you choose a CAT hydraulic breaker for excavators, a JCB hydraulic breaker for excavators, a Kubota hydraulic breaker or a Bobcat hydraulic breaker, you are betting on durability, precision and efficiency. It's equipment that works whether you're forging concrete or working on the road.

Proven hydraulic breakers for excavators with demolition breaker for backhoe loaders - which models are worth considering and why?

When choosing a hydraulic breaker, it's worth betting on equipment that has been tested under real working conditions. In TechnaPoland's offer you will find, among others, the HydroRam HK45 - a versatile model for 3.5-6 t machines, which combines high power with reasonable weight, and the HydroRam HK60 - a more powerful variant for 6-13 t backhoe-loaders, proven in heavier demolitions.

Then there are reliable designs from reputable manufacturers such as the Cat B8 Hydraulic Hammer, which are prized for their durability and low running costs. Each of these models is available from TechnaPoland with full service support, warranty and the ability to match attachments to your specific machine.

Want to make sure you're choosing a hydraulic breaker that's the perfect fit for your machine and the type of work you do? Check out TechnaPoland 's range of hydraulic breakers for excavators with demolition breaker for backhoe loaders and bet on proven equipment with warranty and full service support.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- The wrong breaker is a big problem. How do you choose the right model for your excavator?

- How does a hydraulic breaker work?

- Operating a hydraulic breaker in excavators - how to extend its life?

- When to buy a demolition hammer and when to hire one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hydraulic breaker versus pneumatic breakers for excavators - differences, disadvantages, applications

- Hammer or hydraulic hammer breaker - which will work better on your excavator?

- Don't choose blindly - find out the real differences between hammer and vibratory hammer

- Hydraulic hammer lubrication - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous