Buying a hydraulic breaker for mini excavator is not just a question of price or stock availability. Above all, it's a decision that affects the efficiency of your work, the comfort of the operator and the life of the machine. A hammer that's too heavy can quickly fatigue the arm system, while one that's too weak won't cope with the simplest concrete. If you want to avoid expensive mistakes and fit a hammer that really suits your machine, the scope of work and the intensity of your work, it's essential to find out what to look out for. In this guide you will find specifics, proven examples and technical details.

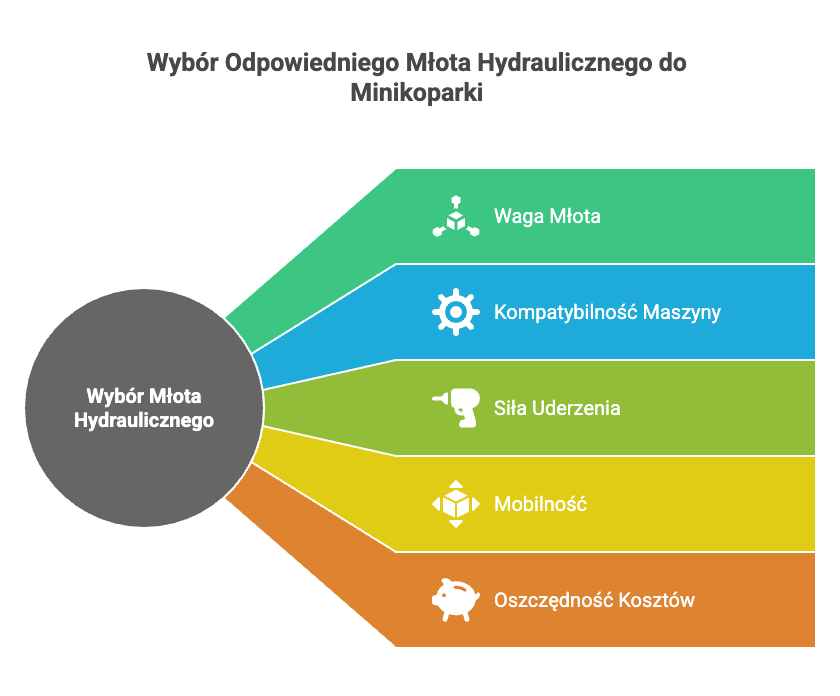

Match the hammer to the strength of your machine - why are weight and oil flow the foundation?

Before you start analysing impact parameters, brand or hammer design, take a step back and look at your mini excavator. It's the one that sets the limits you can't cross - neither in terms of the weight of the attachment nor its hydraulic requirements. A mismatch between the hammer and the capacity of the hydraulic system not only results in a loss of efficiency, but also risks serious damage.

For example, if you have a 2.5 tonne mini excavator that generates a flow of 25-30 l/min and operates at around 110-130 bar, a good choice would be the TE-53 model. This compact but powerful hydraulic breaker weighs 142 kg, operates at a flow of 25-35 l/min and delivers an impact energy of 950 J. In contrast, lighter machines - such as those weighing 1.2-2.0 t - should be fitted with the TE-45 hammer, which weighs only 87 kg and has a flow requirement of just 18-22 l/min.

Too big a hammer with too weak a hydraulic pump? The result is not only non-functioning equipment, but also oil overheating, rapid component wear and the risk of main system failure. Therefore, before you order anything, check:

- theweight of the hammer - it should correspond to the permissible load of the boom,

- the required oil flow - it must be within the capacity range of the pump,

- the operating pressure - it should match the parameters of the hydraulic system.

When in doubt, do not act "on the hunch". Instead of taking risks, it is better to consult a technical advisor - e.g. from the TechnaPoland team - who will select a hydraulic breaker for excavator or mini excavator exactly according to its parameters and the scope of planned work. This will help you avoid costly mistakes and gain maximum efficiency.

Getting the hammer under control - how to choose the optimum energy for the type of work?

If you are planning to carry out paving work, crushing old concrete or demolishing light structures, it will be crucial to choose a hammer with the right impact force. And it's not about having the 'strongest hammer on the market', but making sure its impact energy matches the tasks and capabilities of your machine. Too powerful a tool on a mini excavator that is too light can do more harm than good - from overloading the arm to destabilising the entire hydraulic system.

For mini excavators in the 1.2-2.5 tonne range, a great choice is the TE-45 hammer, which offers an impact energy of around 270 J, which is more than enough for paving, foundation pounding, home demolition and renovation work. It weighs just 87 kg, so it doesn't put any strain on the structure, while still allowing for precise, fast action.

If you're working with a slightly heavier machine, such as 2.5-3.5t, consider the TE-53 model - its impact energy is up to 950J, allowing you to work effectively in demolition, engineering or asphalt crushing. This 142kg model is a great option for those who need more power but still operate a mini excavator.

On the other hand, for really demanding jobs - such as breaking thicker layers of concrete, dismantling old road slabs, removing large pieces of reinforced concrete - reach for the TE-60. This hammer offers up to 1,200 J of percussion energy, which, at 186 kg, gives impressive performance for the toughest off-road tasks.

However, it is not worth overdoing the power. If you choose too powerful a hammer for too small a carrier, you risk damaging the arm, working inefficiently and even overheating the hydraulics.

Hammer weight matters - why is a lightweight model more than comfortable?

When it comes to mini excavators, every kilogram really does make a difference. On the surface it may seem that a heavier hammer is synonymous with more power, but in practice - too much weight of the tool can quickly take its toll on the condition of the arm, cylinders and boom itself. Therefore, if you care about precise work, machine durability and mobility - choose a hammer that won't overload the system, while still retaining sufficient impact force.

A great example of a well-balanced hydraulic breaker for mini excavators is the TE-45 model. Weighing only 87 kg, it means that even a compact 1.2-1.5 t mini excavator can operate it without overloading and without risking rapid wear of bearings or cylinders. Despite its lightweight design, this hammer can easily handle foundation demolition, paving work and minor demolitions that are often carried out in cities.

If your machine weighs around 2.5-3 t, the TE-53 hammer is worth considering, with a weight of 142 kg, which still allows for great manoeuvrability while still delivering higher percussive energy - ideal for medium-intensity work. This type of design is recommended for commercial roadworks, demolition and renovation contractors who need reliability but cannot afford to overload their fleet.

There is sometimes a temptation to 'take something bigger as a backup', but this does not work with a mini excavator in the same way as it does with heavy tracked excavators. A hammer that is too heavy will not only restrict working movements, but can lead to microcracks in the arm, faster wear on the pins or balance problems during transport. What's more - more weight also means higher fuel consumption and less comfortable working in cramped quarters.

In urban areas, fencing, backyard work or infrastructure installation - a lightweight hammer with a well-balanced performance is the best decision. Not only do you gain control of the work, but you also reduce breakdowns and downtime. And that translates into real savings - both in terms of time and money.

Do you work a lot? Opt for a hammer with effective cooling and a simple design.

If you run your hydraulic breaker for mini excavator almost every day without a break, you cannot afford overheating, downtime or breakdowns. Only solutions that are simple, mechanically robust and well cooled work well under these conditions. Without excessive electronics that like to fail in dust and mud.

That's why it's worth taking a look at the TE-53 and TE-60 models. Both have a simplified, robust design and their cooling system is based on proven oil flow - without complications that make service difficult.

Easy access to lubrication points, replaceable bushings and robust dirt guards all mean you can work longer, more smoothly and.... with fewer costs. If you're operating in the service industry and can't afford delays, this type of hammer is a sure bet.

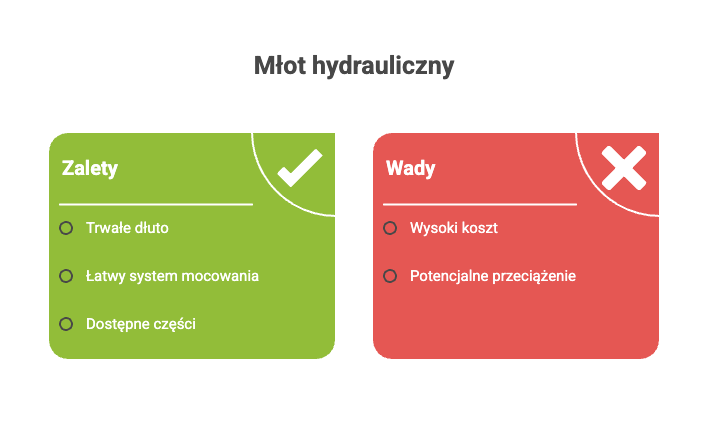

Small detail, big difference - why does the quality of the chisel and handle really matter?

Choosing hydraulic breakers hammers for excavators is one thing - but without a decent chisel and a reliable clamping system, you won't do the job right. Contrary to what you might think, it's these 'small' parts that most often determine whether your equipment works as it should or is serviceable after a few days. And worse - whether it exposes the mini excavator's hydraulic system to unnecessary stress.

For example, models such as the TE-45 and TE-53 use chisels that are hardened, abrasion-resistant and prepared for prolonged use under load. As a result, they last much longer than typical cheap replacements, which in practice need to be replaced even every few days.

Equally important is the clamping system - fast, accessible and easy to service. There is nothing worse than chiselling intermittently.... because you can't unscrew the securing device or have no way of pulling off the old chisel. In the hammers in the TechnaPoland range, the solutions are thought out so that changing the working tool is simple and doesn't require a whole day of combining.

A robust chisel, a rugged handle and easy access to consumable parts - these are really not details to be overlooked. If you plan on heavy use, these are the ones that will make the difference between working quietly and forever looking for service.

For heavy demolition work, a demolition breaker for CAT will be ideal, as will a demolition breaker for JCB excavators. You will also find Kubota demolition hammers and Bobcat demolition hammers, which guarantee excellent impact force and low failure rates.

A handle that won't fail - matching the attachment to the mini excavator model

This subject is often overlooked, and in practice can determine whether it takes 30 minutes or...three days to mount the hammer. The chuck must match the geometry of the quick coupler or arm - depending on the method of attachment. Excessive tolerances, ill-fitting bolts or lack of spacers can effectively block the job.

If you are not sure whether the hammer fits your machine - consult your supplier. At TechnaPoland, you can always choose a hydraulic breaker for excavator demolition breaker for mini excavators, excavators or backhoe loaders with the right adapter. There are also attachment plates for specific quick couplers - such as JCB, Lehnhoff or Verachtert.

Remember: even the best breaker will not do its job if it is not properly fitted. Errors in fitting lead to leaks, backlash and, in the long run, to serious breakdowns in the hydraulic system. It is therefore worth taking care of this at the ordering stage.

Read also:

- The wrong breaker is a big problem. How do you choose the right model for your excavator?

- How does a hydraulic breaker work?

- Hydraulic breakers for excavators with demolition breaker for backhoe loaders - what to look for when choosing one?

- Excavator demolition breaker operation - how to extend its life?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hydraulic breaker versus pneumatic breakers for excavators - differences, disadvantages, applications

- Hammer or hydraulic hammer breaker - which will work better on your excavator?

- Don't choose blindly - find out the real differences between hammer and vibratory hammer

- Hydraulic hammer lubrication - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous