Hydraulic breakers hammers for excavators are equipment that can replace several different tools at once in many situations. Thanks to their combination of power, precision and reliability, they prove their worth in demolition work as well as in roadworks or foundation work. If you want to know how a hydraulic breaker really works, what it consists of and in which tasks it will show its full potential, this guide will take you step by step through all the essential information.

What is a hydraulic breaker for excavators really and why is it replacing traditional tools?

When you look at a hydraulic breaker hammer for excavators, you might get the impression that it's just another piece of attachment - a solid piece of steel that hits hard. But that's just the tip of what it can do. In practice, it is one of the most effective tools in the construction, demolition and mining industry, converting the energy of high-pressure oil into powerful, repeatable impacts. This allows you to crush concrete, asphalt, rock or any other hard material in a short time, without the need for several different machines.

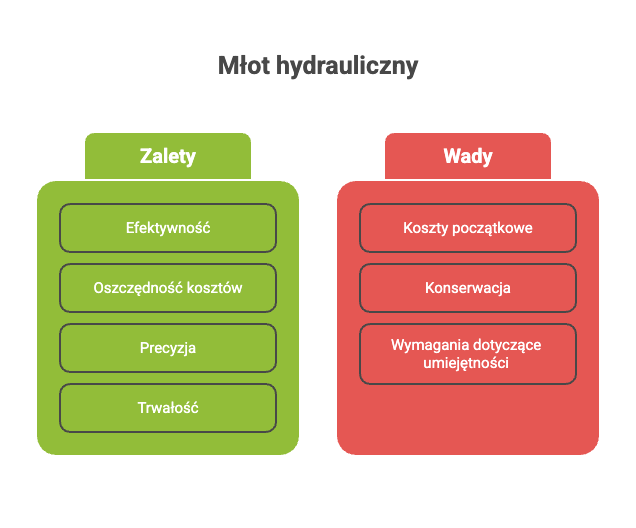

What sets it apart from traditional pneumatic hammers is its use of compressed gas - usually nitrogen - as an additional energy source. The result? Greater efficiency, less strain on the excavator's hydraulic system and real savings in operation. In addition, you have here the possibility to precisely adjust the working parameters to the type of ground, which is of great importance on sites where not only power but also control of the process counts. If you want to reduce the time it takes to complete a job, cut costs and at the same time increase the durability of your attachment, a hydraulic breaker for mini excavators or larger equipment is the tool that can give you this.

What's under the steel shell? Construction of a hydraulic breaker without secrets

Beneath the sturdy steel casing is a complex array of components that must work together in perfect harmony.

- The heavy-duty steelbody not only protects the interior from damage, but also dampens vibrations and reduces noise thanks to polyurethane cushions.

- Inside, you'll find the cylinder, which houses the beater - a heavy component made of hardened steel, responsible for transferring the energy of the impact to the blade.

- Then there is the control valve, which directs the flow of hydraulic oil in the correct sequence, and the gas accumulator, filled with nitrogen, which stores energy during the lifting phase of the beater and releases it at the moment of impact.

- The entire assembly is held in a stable position by through-bolts, and the precision of the tool is ensured by guide bushings and wedges.

- At the end is the working blade, which can be conical, flat or pointed - depending on the material you are working with.

Regular lubrication and wear control is key here, as neglecting this can lead to premature failure and even costly downtime on site.

A professional hammer for excavators with demolition breaker for CAT or a hammer for JCB excavators is an investment that translates into efficiency and speed of the work being carried out. Also check out hammers for Kubota and hammers for Bobcat - ideal for mini excavator and mini loader operators.

Five phases in one second - how does a hydraulic breaker cycle work in practice?

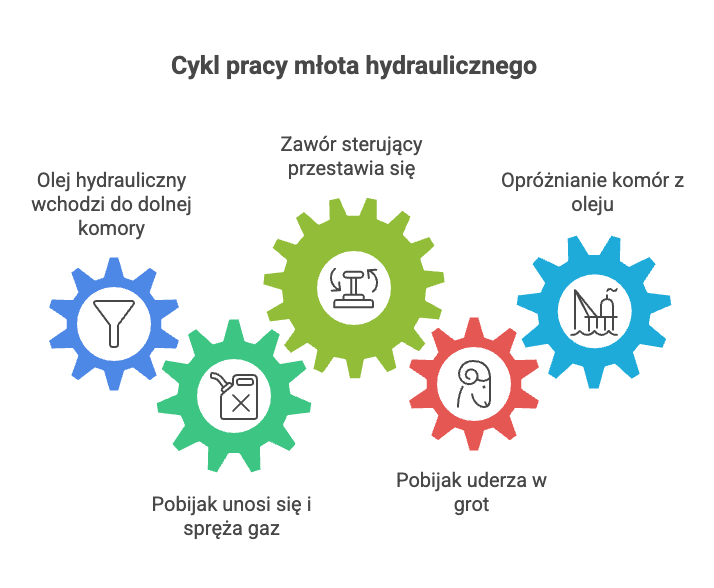

The performance of a hydraulic breaker for excavators with demolition breaker for backhoe loaders is due to the lightning-fast repetition of the work cycle, which consists of several precise phases. First, high-pressure hydraulic oil enters the lower cylinder chamber from the excavator pump. This raises the beater and simultaneously compresses the gas in the accumulator. In the next step, the control valve shifts, directing the oil into the upper chamber and opening the outlet from the lower chamber.

A key moment occurs - the compressed gas and oil pressure rapidly push the beater downwards, causing it to strike the spearhead, which transfers energy to the crushed material. The final phase is to empty the chambers of oil and return the beater to its starting position. The whole process takes a fraction of a second, but when repeated up to several hundred times a minute, it allows for incredible working efficiency. If you want to use the hammer to its full potential, you need to ensure that the optimum oil flow and adequate nitrogen pressure are maintained - these determine the strength and smoothness of the impacts.

Power under control - how the valve, gas accumulator and beater work to maximise impact

In a hydraulic breaker for excavators (and more), it's all about three key components working together: the control valve, the gas accumulator and the beater.

- The valve is responsible for ensuring that the oil reaches the correct cylinder chambers at the right time.

- The gas accumulator, filled with nitrogen, stores energy as the beater lifts and releases it at the moment of impact, increasing its power.

- The beater is the final link here - it is the one that physically transfers energy to the working blade.

If any of these components are not working properly, you will feel it immediately in the operation of the machine - the strokes will be weaker, the work will be less smooth and productivity will drop. That's why regular maintenance, checking gas pressure and valve performance is so important. In a well-maintained excavator with demolition breaker, these three components operate in full synchronisation, allowing maximum force to be achieved with minimal stress on the excavator's hydraulic system. This translates not only into better results, but also a longer life for the entire working set-up.

From roads to quarries - where does a hydraulic breaker show its advantage and when is it worth using?

The applications for hydraulic hammers are truly wide-ranging and include both typical construction work and specialised tasks.

- In demolition, they make it possible to break reinforced concrete or concrete quickly and precisely, which is particularly important in city centres where noise and vibration reduction is important.

- In roadworks, they are excellent at removing asphalt or concrete surfaces, reducing repair times.

- In mining and quarrying, they are invaluable for breaking up large blocks of rock, and in foundation work for drilling holes in extremely hard ground.

- They are also increasingly used in underwater work (with the right attachments), and in municipal work for removing kerbs, pavements or terrain obstacles.

If you want a piece of equipment that will work in a variety of conditions and perform well in many projects, investing in a hydraulic breaker is one of the more cost-effective decisions. After all, one piece of equipment can replace several other machines, providing flexibility and time savings.

Looking for a hammer that is perfectly suited to your machine and the type of work being carried out? Check out TechnaPoland 's range of hydraulic breakers for mini excavators and choose a solution that will give you performance and reliability in all conditions.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- The wrong breaker is a big problem. How do you choose the right model for your excavator?

- Hydraulic breakers for excavators with demolition breaker - what to look for when choosing one?

- Excavator demolition breaker operation - how to extend its life?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hydraulic breaker versus pneumatic breakers for excavators - differences, disadvantages, applications

- Hammer or hydraulic hammer breaker - which will work better on your excavator?

- Don't choose blindly - find out the real differences between hammer and vibratory hammer

- Hydraulic hammer lubrication - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous