If you've bought a hammer for excavators with demolition breaker at least once, you know one thing - catalogues don't tell the whole truth. Everything looks good on paper: percussion power, pressure, performance. And then comes everyday life on site, the terrain isn't the same, people are tired, the material is stubborn. And that's when it turns out that you've chosen equipment that, in theory, "should be able to do it". In this blog post you won't be reading about which hammer "is stronger" or "better for C25 grade concrete". Instead, you'll get an honest comparison of two worlds: the hydraulic, which gives precision and stability, and the percussion, which tempts you with simplicity and price.

One hammer, many misunderstandings - what's the real difference between hydraulic and impact?

Contrary to appearances, it's not just about the name. Although both types of hammer have one main task - to smash, crush and demolish - their design, operation and capabilities in practice are completely different. The differences do not stop at catalogue impact values or working pressure. And it is because of these simplifications that many companies make decisions that are not quite right, which then result in frustration on site.

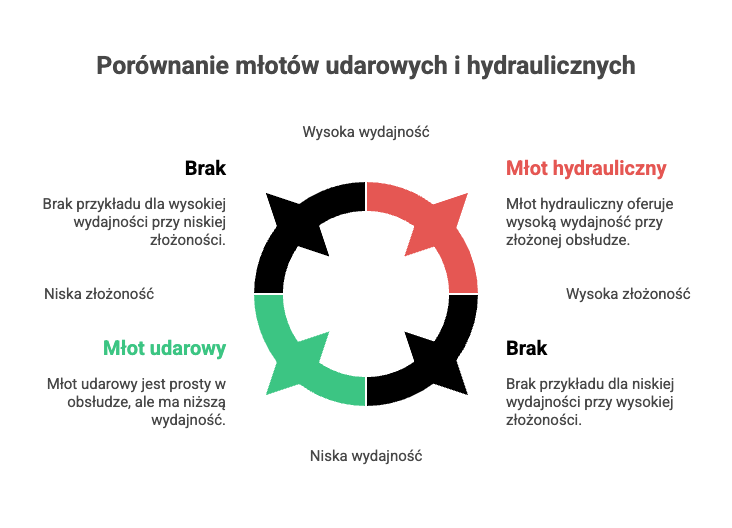

Hydraulicbreakers hammers for excavators are modern solutions based on a piston powered by high-pressure oil, assisted by a gas accumulator. This gives you high impact energy while maintaining control, precision and flexibility of operation. Impact hammers (pneumatic-impact hammers), on the other hand, operate with a simpler mechanism - often based on compressed air or mechanical impacts transmitted through a shaft. It sounds similar, but the difference in the end result is huge.

On a construction site, this translates into one thing: a hydraulic breaker can handle thick concrete, deep foundations or asphalt, where repetitive, powerful force is needed. A percussion hammer will work well for lighter jobs, quick demolitions or the occasional job where you don't need as much power, but more mobility and simplicity. The conclusion? If you choose equipment blindly, you may end up exactly where you need to be.

Impactor or hydraulic? It's not the price that decides, it's how you actually work

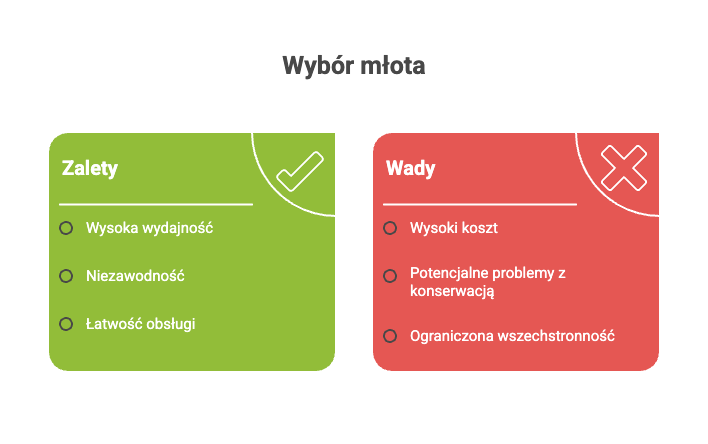

From a buying perspective, this looks like a simple dilemma: one hammer costs less, the other more - but if you stop at just this difference, you can easily fall into a trap. In reality, what says the most is not the price, but how your team works in practice. What is the intensity of the jobs? How long do the jobs take? What materials need to be broken down? It is these factors that realistically determine the choice.

Ahydraulic breaker for mini excavator or excavator demolitionbreaker is an investment. It costs more - both purchase and service - but it gives you more where you need it. If you regularly carry out demolition work, run linear projects, work on road infrastructure or industrial demolition - this equipment simply has to be in your arsenal. A hammer like this doesn't fail in the middle of the season, doesn't whimper on hard ground and doesn't require a "feel" for the machine. It simply gets the job done.

An impact hammer, on the other hand, will find its place in companies that operate occasionally in the area of demolition or want something versatile "for backup". If you don't work in C40-grade concrete every day and don't need to demolish columns in centimetre-long layers, you may not need a heavy-duty hydraulic, just a capable impact hammer. Especially if your operators are inexperienced with larger hammers or work in variable conditions.

Quieter, safer, more precise - when a hydraulic breaker does the job better

There are situations where there is no debate - if you are concerned about working comfort, less noise and people's safety, the choice should fall on a hydraulic breaker. Modern models are equipped with vibration dampening systems that significantly reduce the level of vibration transmitted to the machine and operator. This makes a real difference to the health, productivity and reduced fatigue of the crew.

In addition, hydraulic hammers offer greater precision - you can precisely dose the force, number of blows and tailor the work to the specific material. When demolishing structural components, where you're concerned about avoiding damage to the surrounding area, such equipment gives you much more control than an impact counterpart. And it's not just about convenience - in many cases it's simply a necessity due to the technology of the work.

It's also worth remembering that hydraulics stand up better to continuous operation, even in high ambient temperatures or difficult terrain. Hammers of this type are designed for heavy, long-term use, making them the ideal tool for companies working in multi-shift operations on large infrastructure projects. If your job calendar is bursting at the seams, hydraulics will simply pay you back.

When simplicity and concreteness count - what tasks is an impact hammer unbeatable at?

Although an impact hammer may seem more modest compared to a hydraulic hammer, it has its absolutely legitimate place in the market. Where fast response, low cost of entry and simplicity of operation are important, it is this type of equipment that works best. If you run a small construction company, work locally and are not breaking tens of tonnes of concrete every day - an impact hammer will simply be more practical.

It's great for less demanding jobs like minor demolition, paving removal, light foundation or installation work. Importantly - most impact models don't require extensive hydraulics and are cheaper and quicker to service. In the event of a breakdown, you're not standing around for weeks waiting for a dedicated service technician - a simple in-house repair is often enough.

Remember too that impact hammers are often smaller and lighter, giving you more freedom in confined spaces. If you're working close to buildings or in hard-to-reach areas - this aspect can determine your choice. And while it may not smash every obstacle in its path, it can often handle more quickly than a larger but more demanding hydraulic hammer.

Whether you need:

- a hydraulic breaker for excavators with demolition breaker for CAT,

- a demolition breaker for a JCB,

- a breaker for a Kubota mini-excavator,

- or a breaker for a Bobcat

- Here you will find equipment that can cope with even the hardest ground.

Hydraulic hammer or demolition breaker excavator - which really suits your excavator and the people in your team?

The final decision should not be made on the basis of a catalogue. What works on paper doesn't always work in your reality. Every machine has its limitations, every team has its own working rhythm and every project has different requirements. When choosing a hammer for excavators with demolition breaker, don't just look at hitting power - look at what equipment you need for your working style.

If you have a large fleet of machines, experienced operators and extensive technical facilities - a hydraulic breaker will fit in naturally. It will work evenly with the rest of the team, won't be a bottleneck and will deliver quality where you can't afford to compromise. In the long term , it's a more stable, predictable and cost-effective choice, despite the higher entry threshold.

But if you operate in a changing environment, do a variety of jobs and want versatile equipment - an impact hammer will be simpler, more accessible and easier to implement even for less experienced operators. Less weight, easier installation, lower technical requirements - these are features that often determine the efficiency of small teams.

The choice is therefore not zero-one. Match the hammer not to the table, but to the people, the machines and what your working week looks like in the field. Because it is there - not in a catalogue - that a hammer shows whether it really gets the job done.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- The wrong hammer is a big problem. How do you choose the right model for your excavator?

- How does a hydraulic breaker work?

- Hydraulic breakers for excavators with demolition breaker - what to look for when choosing one?

- Excavator demolition breaker operation - how to extend its life?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hydraulic breakers vs. pneumatic breakers for excavators - differences, disadvantages, applications

- Don't choose blindly - find out the real differences between a hammer and a vibratory hammer

- Lubricating a hydraulic hammer - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous