Not every construction site looks the same - and certainly not every hammer will cope with all conditions. Sometimes it's power and repeatability that counts, other times it's simplicity and mobility. And this is where the topic that comes up regularly in conversations between operators, managers and construction company owners begins: hydraulic or pneumatic - which hammer for excavators to choose and when? It's not about which is 'better'. It's about which is better suited to your job, conditions, people and budget.

Hydraulic breakers or pneumatic breakers for excavators - what's the real difference between the two?

Although at first glance both types of hammer do exactly the same thing, i.e. smash, crush and hammer, the differences between the two are important and influence the choice of equipment for a specific application. When choosing a hammer for excavators with demolition breaker excavators, it is not enough to look at price alone - you need to understand how each works and what environment it feels most comfortable in.

Hydraulicdemolition breakers for excavators rely on energy flowing from the machine's hydraulic system, most often powered by pressurised oil and supported by a gas accumulator (usually filled with nitrogen). Such a system gives high power, adjustability and high precision impacts. Importantly - everything happens within the closed circuit of the machine, without the need for an external power supply. Pneumatic hammers, on the other hand, need a compressor, as their heart is a piston driven by compressed air. Such a mechanism is lighter and simpler, but also less precise and requires an external air source.

If you are dealing with hard concrete, rocks or asphalt - a hydraulic hammer will do much better, especially in continuous operation. On the other hand, for lighter jobs where mobility and simplicity of operation are important, a pneumatic one may prove more manageable and sufficient. It is this difference in "working weight" that often determines the choice.

Performance, service and safety - how do hydraulic and pneumatic breakers compare in practice?

When you enter a construction site with a hammer, what matters is not just whether it will work, but how it will work in the long term, how much it will cost in the process and how the operator feels about it. In these aspects, the differences between a hydraulic hammer and a pneumatic hammer become really apparent.

In terms of performance, hydraulic breakers for mini excavators definitely lead the way. Thanks to the piston and gas accumulator, they can work with a lot of force without losing precision. They also have vibration dampening systems that not only protect the machine, but also increase operator comfort. In practice, this means less fatigue, better control and less risk of injury from prolonged exposure to vibration.

With pneumatic hammers, the situation is different. They are noisier, generate more vibration and require a compressor, which introduces additional noise and limits working freedom. Admittedly, their design is simpler - fewer parts mean fewer things that can break - but there is no denying that in terms of safety and comfort, hydraulics win out.

When it comes to servicing, you can also see the difference. Hydraulic breakers require regular servicing, replacing seals, checking gas pressure. It's a more complex system, but if it's well maintained, it repays the favour with reliability. Pneumatic units have fewer service points, but compressor failures or leaks in the system can effectively bring the whole project to a halt.

You'll find hammers for CAT crawler excavators, hydraulic breakers for JCB excavators, hammers for Kubota mini excavators and hammers for Bobcat, among others. Each model is designed for maximum impact force and reliability.

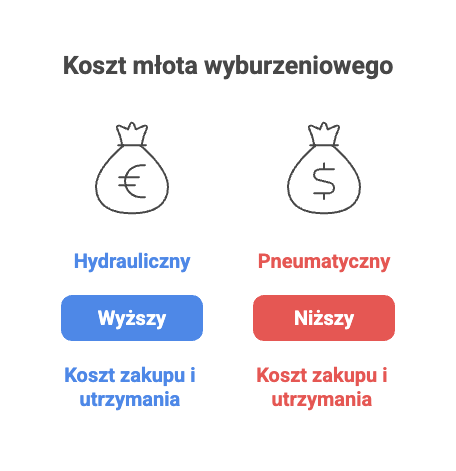

Purchase and maintenance costs - when does hydraulics pay off and when is it worth going down for air?

The purchasing decision is always a balancing act between budget and needs. Hydraulic hammers cost more - both to start and to maintain. They consist of more components, need hydraulic oil, servicing and often specialist support. But at the same time they offer more power, durability and the ability to work in demanding environments.

Air hammers are cheaper to buy and have lower operating costs. The simple design means fewer potential faults, less need for spare parts and easier servicing. But it's fair to add here - these gains end where the serious work begins. Because if you're using the equipment for intensive crushing of concrete, rock or asphalt, the low price of a jackhammer may be illusory - it simply won't hold up under the strain.

The table in the file makes this clear: a hydraulic demolition breaker for excavators withdemolition breaker for backhoe loaders or excavators is an investment that pays for itself in the long term with heavy work, while a pneumaticbreaker is a sensible choice with occasional use and a limited budget. On top of this, you have to add the infrastructure: hydraulic requires a machine with a powerful system, pneumatic requires access to a compressor. Each solution therefore entails additional costs depending on the working conditions.

Hydraulic vs. pneumatic hammers - when is a hydraulic hammer the right choice for a construction site?

There is no one-size-fits-all choice. Which hammer will do the job better depends on the conditions you are working in and what you want to achieve. If you are breaking reinforced concrete at heights, working with large structural components or often operating in variable terrain - a hydraulic breaker will be a more versatile and reliable solution.

On the other hand, for smaller jobs - such as demolishing thin layers of concrete, installation work or ancillary works - a lighter jackhammer will allow faster deployment without putting a strain on the machine system. Especially when we are talking about temporary applications, emergency work or limited access to heavier equipment.

It is clear from the file: hydraulic hammers dominate where strength and power are needed, while pneumatic hammers are better suited for auxiliary work and light construction work. Here and there there will be specific applications - the trick is to get it right for the conditions, rather than going for the 'most popular' solution.

Pneumatic or hydraulic hammer - it's not just the impact force that counts

The final choice between a hydraulic and a pneumatic hammer should not come down to catalogue parameters alone. Of course, impact force and percussion energy are important numbers - but they are only a fragment of the reality on site. What also counts is the availability of the equipment, the competence of the operators, the infrastructure in which you are working, and... time.

A hydraulic hammer gives you more options in terms of adjustment, vibration dampening and adapting the force to the material. But it also requires a functioning hydraulic system on the machine, servicing and more thorough condition checks. A pneumatic is simpler but a little 'rougher' in operation - less precise, noisier, more prone to vibration.

The decision should take into account not only how the equipment performs on paper, but how it functions in your working rhythm, with your people and on your sites. If you need maximum efficiency - go for hydraulics. If time, lightness and simplicity are important - don't be afraid to reach for pneumatic. The right attachment for excavators is the one that realistically fits your job, not the one that has 'better performance' in the brochure.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- The wrong hammer is a big problem. How do you choose the right model for your excavator?

- How does a hydraulic breaker work?

- Hydraulic breakers for excavators with demolition breaker - what to look for when choosing one?

- Excavator demolition breaker operation - how to extend its life?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hammer or hydraulic hammer breaker - which will work better in your excavator?

- Don't go in blind - find out the real differences between hammer and vibratory hammer

- Hydraulic hammer lubrication - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous