Most breakaway jaw failures do not start with spectacular cracks, but rather with minor negligence. Lack of grease in a sensitive area. Working for too long without a break. Working at too high a pressure because "just one more wall". You know it? That's right.

And then comes the downtime, the cost, the nerves. And yet, you only need to stick to a few specific rules to get the best out of your attachment - without the risk of something going wrong at the least opportune moment. See how to service crusher jaws so that they will repay you with long-lasting reliability.

Everyday on a construction site, but without the risks - or how to use crushing jaws so that they don't get damaged after a few jobs

First of all, it is worth understanding that crushing jaws are a powerful tool, but also highly sensitive to poor use. The strength of the steel alone will not be enough if you load the structure in an inappropriate way or exceed a working range that the manufacturer has not anticipated. It's not just a question of equipment - it's also about your safety and the continuity of the work.

Proper operation begins... before you even fire up the machine. Fitting the jaws to the machine, properly adjusting the operating pressure, checking the oil, and carefully checking the demolition material for steel reinforcements or fragments of hard structures - these are the things that can determine whether the jaws will last for months or end up in the service department after the third job.

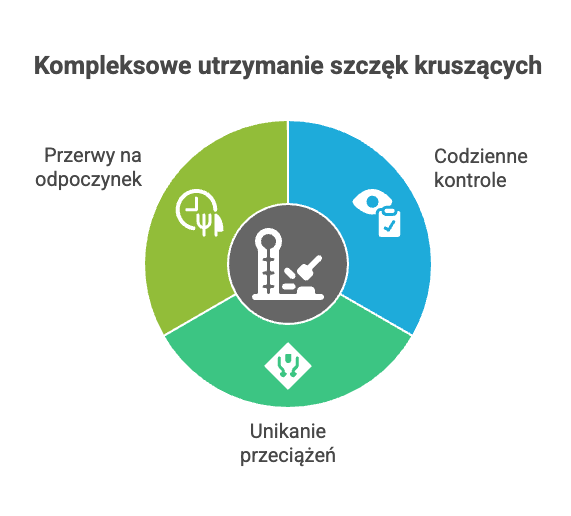

Don't underestimate how long they work, either. Continuous operation for several hours without a break, especially in high temperatures, is a huge risk of overheating the cylinders and losing working power. As a result, the cutting tips wear out faster and the whole tool starts to work with less efficiency. And from that, it's only a step to damage that you don't foresee - and which could be avoided by following a few simple rules.

Check, lubricate, don't overload - a few simple things that make a difference in the long run

You don't need a separate serviceman to look after your jaws. The things that really matter can be done every day, in 10 minutes. Regularly checking clearances, fixing bolts, the condition of hydraulic connections and cutting elements is fundamental. Even the best-built machine wears out over time - but you can extend its lifespan by up to twice as long as you maintain a systematic approach to daily maintenance.

It's also important to know what not to do. Overloading the tool, crushing with maximum force without adjusting the angle of attack, hitting the jaws in a way that resembles the work of a demolition hammer - these are mistakes that at first glance speed up demolition, but in practice only damage the equipment. Jaws are not for breaking everything - they have their own specifications, and exceeding them always ends up costing money.

Equally important are the breaks. Not just for the operator - also for the equipment. Every so often, let the cylinders rest, reduce pressure, give the hydraulic system time to cool down. It's the little things that make a real difference to the longevity of the entire attachment. Even if the budget is chasing and the pace needs to be maintained - believe it, a short break every hour can save you weeks of unproductive downtime later.

Not every weather and not every job is a good time - know the conditions when it's not worth the risk

Although the crusher jaws look massive and 'unbreakable', their operation in extreme conditions can result in microcracks, hydraulic leaks and even damage to the cylinders. When the air temperature exceeds 35°C, the hydraulic system operates at higher pressure and the lubricant loses its properties. Conversely, in winter, below -10°C, the oil thickens and the cylinders become less reactive. As a result, damage can occur with sudden overloads or dynamic operation of the jaws.

It is not just the weather that can be a problem. Changing terrain, sloping work, unstable ground or rebar fragments hidden in debris can all cause uncontrolled jaw movements and structural overloads. If you don't adjust your working parameters to such conditions, you risk not only equipment failure but also accidents on site.

In practice, it is best to take maintenance breaks every 50-60 minutes or so of continuous operation, check the temperature of the hydraulic oil and avoid working in extremely dusty environments without cleaning the equipment first. Sound simple? Because it is the simple things that have the biggest impact on the life and performance of the attachment.

Teeth work but no longer cut - a list of omissions that end up in the workshop instead of on site

One of the biggest mistakes is treating demolition jaws as a 'do-it-all' tool. In practice, a large proportion of failures are due to the attachment being used for the wrong purpose - such as crushing rubble containing rebar, hitting the ground to 'improve' foundations or undermining structures. Jaws are not a crowbar or a hammer - they have their limitations.

The second problem is the lack of daily maintenance checks. Users often neglect to check oil levels, the condition of the pins, blade wear or possible hydraulic leaks. Yet it only takes one defective o-ring for the entire system to lose pressure and the jaws to stop working effectively. Often, it is only a drop in cutting force or unnatural noises that triggers a reaction - and unfortunately it is sometimes too late.

On top of this, there are errors due to lack of training. It is easy for an operator who is unfamiliar with the design of the jaws to overload the ram, misalign the working angle or even cause the working jaws to break. From a workshop perspective, it's a classic, but for the developer it's unnecessary costs and downtime. Remember - you don't have to do anything wrong, just not do it right.

You don't need to know all the hydraulics - just do these things regularly

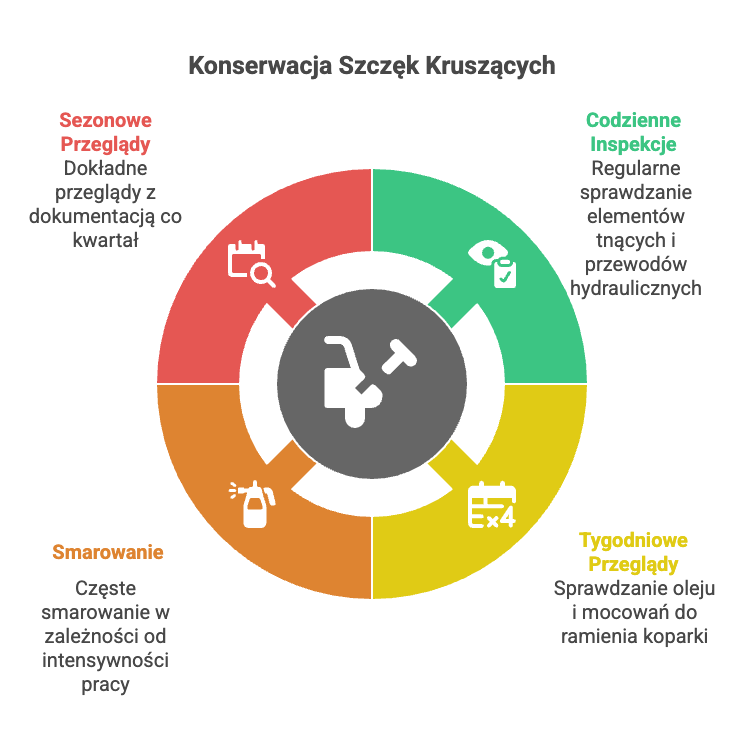

Jaw service is not complicated, but it must be systematic and based on specific checkpoints. First and foremost: daily inspection of the cutting elements, hinges, cylinder ends and hydraulic lines. Even a minor leak or play can quickly develop into serious damage. The earlier you spot a problem - the lower the cost of repairing it.

It is a good idea to schedule a fuller inspection once a week. Check the oil level and quality for metal filings, foam or discolouration. Inspect the attachments to the excavator arm - a critical point that is very often overlooked. Vibrations, oscillations, sudden jerks - all contribute to wear on this component. If necessary - tighten, clean, lubricate.

Don't forget to lubricate. The frequency depends on the intensity of the work, but a good rule of thumb is: if in doubt, lubricate. Only use lubricants recommended by the manufacturer - the wrong lubricant can damage the actuator's working surface in the long run. Remember seasonal maintenance too - do a thorough inspection with documentation at least once a quarter.

Less downtime, more safety and... lower costs - it all starts with a routine

Sound boring? Possibly. But it's the routine, repetitive operation that has the greatest impact on the longevity and efficiency of crushing jaws. When you're working on a project system, every delay translates into money. And delays resulting from fixture failures are some of the most frustrating - especially when it turns out they could have been prevented with one lubrication or a 10-minute pre-work inspection.

Secondly - safety. Broken cylinders, loose jaws, leaking hydraulics - these are real hazards not only to the equipment, but also to people. Even if the risk is small, it is not worth ignoring warning signals. A malfunctioning attachment means an unstable machine, a drop in precision and a greater risk of human error.

And finally - the economy. Well-operated jaws not only last longer, but also use less fuel (because the system does not have to compensate for pressure drops), do not require frequent replacement of parts and can be used on different projects without costly adjustments. All of this translates into real savings that you can't see on the invoice, but which grow with every week of operation.

This equipment will give its all - as long as you give it what it needs

In summary: crushing jaws are demanding, but not difficult to operate. They need one thing - attention. If you devote a few minutes a day to them, they will repay you with hundreds of hours of efficient operation without failure. How long they last and how effectively they work depends largely not on the manufacturer, but on you.

Don't ignore the basics. Lubrication, checking clearances, watching the actuators - these are not details. They are the foundation of daily operation. Don't treat maintenance as a chore either, but as an investment in peace of mind - yours, your operators and your business.

Well-maintained jaws not only cut better, they cut longer. And that - as you know - translates into profit. And a very tangible one at that.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous