In theory, the choice looks simple - one hammer crushes, the other vibrates. But in practice... it's easy to choose not the one that will actually do the job. A hydraulic breaker and a vibratory breaker are two different worlds - different operating mechanisms, different end results, different technical needs. One will work well on reinforced concrete, the other on sheet piles.

Hydraulic breakers or vibratory breakers for excavators - a decision that doesn't just come down to price

If you're looking to buy or hire attachments for excavators to do the 'heavy work', then you know one thing - before you look at the price list, you need to know what you really need. Because price isn't everything. Sometimes you save money on equipment and then lose out doubly - on time, effect and the cost of fixes.

Hydraulic breakers for excavators and vibratorybreakers forexcavators work very differently - they're equipment for completely different applications, although from the outside it may seem like similar machines. A hydraulic breaker is meant to hit - hard, rhythmically, precisely. It is a tool for crushing, demolition, breaking up hard structures: concrete, rock, asphalt. The vibrohammer, on the other hand, does not break, but transfers the vibrations to the elements to be inserted into the ground - piles, sheet piles, pipes, steel profiles. This is a fundamental difference that many people forget about at the purchase stage.

Choosing one of these two pieces of equipment is not a matter of taste or a promotion from a distributor. It's a decision that comes from the type of work you're doing, the type of substrate, the type of machine you have on site and the objective you want to achieve. If you buy a vibratory hammer in the hope of breaking up a concrete slab with it - you will lose that investment at the start. Conversely, if you use a hydraulic hammer to plunge cofferdams, you will end up with damaged components or a machine standing around with a helpless operator.

Hydraulics in practice - what does a hydraulic hammer do when the job gets really tough?

If your job requires getting into concrete, asphalt, rebar or rock, there's no debate - a hydraulic hammer will be the best tool for the job. Not only do today's models offer high impact force, they also offer a range of features that really improve comfort and protect the machine - such as anti-vibration systems, overload sensors and the ability to fine-tune the impact force. All this is not just a technical curiosity - it is concrete support on difficult construction sites.

The best hydraulic hammer models operate at pressures of more than 160 bar and achieve up to 1,000 to 1,400 blows per minute, giving real efficiency when breaking road surfaces, foundations or cable passages in hard ground. At the same time, it is important: this force is not distributed chaotically, but controlled. The operator has an influence on the rhythm, working depth and load distribution, which is important not only for the effect, but also for the technical condition of the machine.

Importantly, hydraulic hammers are much more resistant to extreme terrain than vibratory hammers. Where durability, intensity of work and lack of time for servicing matter - hydraulics wins. However, it is fair to say that this solution costs money. Both the purchase and operation of a hydraulic breaker require a budget and technical facilities that not every company has. But if you are doing 'hard' work - this equipment simply has to be in your kit.

A vibratory hammer for an excavator - equipment that 'talks' to the ground rather than breaking it up

If your job is not demolition, but foundations, cofferdams, soil reinforcement, installation of steel elements in the ground - you don't need a hammer, you need a vibrohammer. The difference in approach to the work is dramatic. It's not about breaking up, it's about vibrating the ground and reducing its resistance. The purpose of the vibrohammer is to reduce friction and allow the steel elements to 'slip' into the ground on their own, without additional pressure or impact.

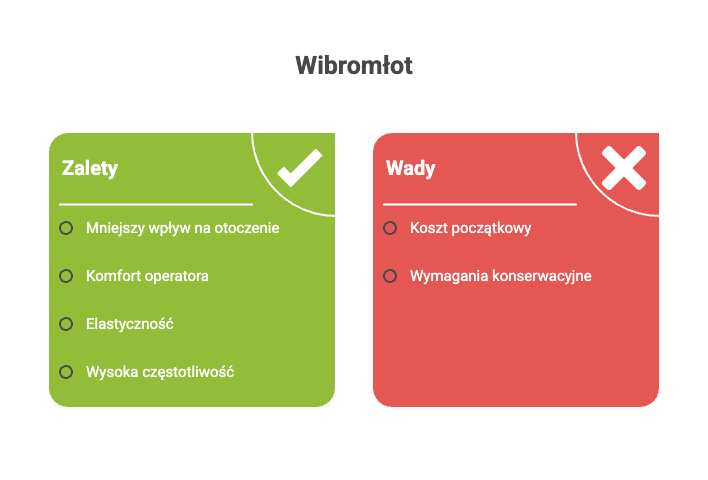

Modern vibrohammers generate very high frequency vibrations - from 1,500 to as many as 2,500 cycles per minute, which enables fast and effective plunging even in medium-compacted soils. Importantly, this type of machine has less impact on the surrounding area. If you are working close to buildings, underground infrastructure or in protected areas - the vibrohammer is often the only acceptable solution.

Operator comfort and noise levels are also important. Vibrohammers emit fewer decibels, have lower vibrations transmitted to the cab and do not require as much experience in handling as hydraulic hammers. In addition, some models are adapted to smaller machines - including mini-excavators and backhoe loaders - giving great flexibility for smaller-scale projects.

Invest in attachments that will increase the capabilities of your machine. Our range includes a hydraulic breaker for excavators for CAT, a breaker for JCB, a breaker for Kubota and a Bobcat demolition breaker - equipment that combines power, precision and resistance to heavy use.

Hydraulic hammers vs. vibratory hammers - a no-brainer comparison: performance, cost, environmental impact

When comparing hydraulic hammers and vibratory hammers, it is worth taking a broader look at the topic than just "which will make a hole in the concrete faster". It is about the complete technical, operational and performance balance. And this looks very different depending on what you are dealing with on site.

Hydraulic breakers are irreplaceable for hard work, but they are also more demanding - they weigh more, cost more, need more powerful carriers, generate more load on the arm and wear out some excavator components more quickly. Added to this is the need for regular maintenance, proper selection of gas batteries and checking for leaks in the system.

Vibrohammers are simpler to operate and cheaper to run, but have their limitations - they are not suitable for crushing, do not work in hard rocky ground and can have difficulty in clay soils. With them, it is crucial to properly tune the frequency and strength of the vibration to the ground conditions - otherwise not only will the sinking be ineffective, but the cofferdams or pipes may be damaged.

Noise and impact on the surroundings is another important point of comparison - where a hydraulic hammer can generate up to 120-130 dB and transmit high vibrations to the surroundings, a vibrohammer allows this level to be lowered by several tens of per cent. For urban developments, infrastructure projects or built-up areas, this is not so much a plus as a prerequisite.

Hydraulic or vibrohammer - in which scenarios it is not worth making a mistake

Finally, the specifics. If you're doing a bridge demolition, cutting out sections of reinforced concrete, preparing a route for an industrial installation or need to cut through an old foundation - hydraulic will be the only way to go. Don't even look towards a vibrohammer. He's just not up to it - it's a different league, a different task, a different philosophy of working.

But if you've got a job to do - plunging steel sheet piles, placing pipes in the ground, medium-depth piling, reinforcing slopes - then a vibrohammer will do it faster, quieter and more efficiently than a hydraulic hammer. What's more, it will often be the only tool that will be allowed to work on a site at all - for example on hydraulic works, within a city, on existing underground infrastructure.

And here we are back to where we started - don't just look at the parameters, look at the needs. Equipment is chosen not by hitting power or price per hour, but by what you realistically have to do. If you get the hammer right - you won't come back to it for months. And if you get it wrong - it's not just your money, but your entire work schedule that will go down the drain.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- The wrong hammer is a big problem. How do you choose the right model for your excavator?

- How does a hydraulic breaker work?

- Hydraulic breakers for excavators with demolition breaker - what to look for when choosing one?

- Excavator demolition breaker operation - how to extend its life?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hydraulic breaker versus pneumatic breakers for excavators - differences, disadvantages, applications

- Hammer or hydraulic hammer breaker - which will work better on your excavator?

- Hydraulic hammer lubrication - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous