Choosing a drilling rig is not just a question of well diameter or auger length. It's a decision that affects the pace of work, the comfort of the operator and the final cost of completion. And when you have three different types to choose from - hydraulic, mechanical and pneumatic - it's easy to fall into the 'by eye' trap.

In practice, each works differently and each has its own specific niche. One gets the most out of an excavator in heavy terrain, another will work well on light garden work and a third will manage where other equipment won't even start. There is no one-size-fits-all solution, but there are specific criteria to help you decide.

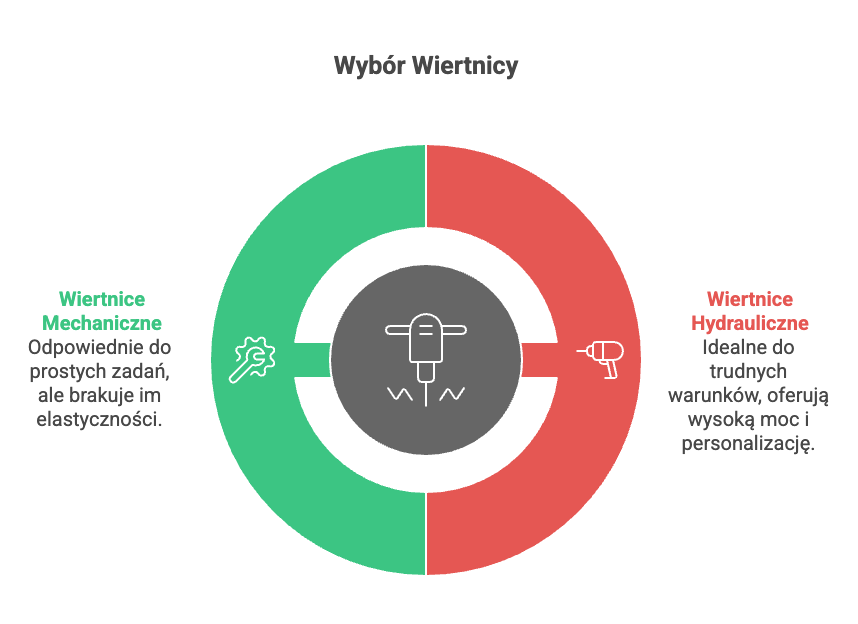

Hydraulic earth auger or mechanical drill - which will work when the ground starts to resist?

When choosing a drilling tool, it 's worth asking yourself: will the ground dictate the conditions, or do you have the equipment to cope with them? If you assume you are working in difficult, compact or rocky ground, there is no room for compromise. In such situations, drive power is critical, and it is the hydraulic system that can generate the highest torque while maintaining stable performance.

Hydraulic earth augers are designed to operate in extreme conditions. Their working system operates independently of the speed of the carrier engine, allowing the parameters to be precisely adapted to the type of ground. This is not offered by classic mechanical solutions. If you plan to drill in rock, concrete or frozen ground - only a hydraulic drive will ensure uninterrupted, stable operation, even in multi-shift operation.

Interestingly - it is hydraulics that gives you the greatest scope for personalising your equipment. You have control over downforce, torque and even direction of rotation, which has a real impact on drilling efficiency and operator safety. Mechanical drill rigs, while popular, do not have this flexibility. They either work or they don't - and it is not very possible to adjust this 'on the fly'.

When choosing attachments for excavators, it is worth looking at hydraulic earth augers for excavators from Bobcat, which provide precise operation even in confined spaces. In the medium-sized segment, a hydraulic earth auger for mini excavators from Kubota, valued for its durability and simple operation, will be an excellent choice. For larger constructions, the CAT hydraulic earth auger for excavators remains an excellent solution, while the JCB hydraulic earth auger for JCB machines will be an alternative that guarantees longevity of work.

Mechanical classics on a construction site - when less advanced technology will do

Not every job requires maximum power and advanced electronics. Mechanical drill rigs still have their place - and quite deservedly so. For light to medium work, such as drilling for fences, foundations for small structures or geotechnical test boreholes, a simple mechanical drive proves sufficient and sometimes even more cost-effective.

Mechanical solutions are tempted by simplicity of servicing and availability of parts, and this is of paramount importance to many companies. The absence of complex hydraulic systems means less risk of failure, lower operating costs and shorter downtime. For small construction companies that operate locally and do not need to drill at great depth - this is often the most sensible choice.

However, it is worth remembering that mechanics have their limitations. Changing the operating parameters often involves interfering with the gearbox, and the process itself can be less precise. Then there is the issue of wear and tear - with intensive use, mechanical gears lose efficiency more quickly, which can take its toll on the quality of the bore. Therefore, if you plan to drill frequently or for longer periods - it is worth thinking about a solution that will give you more control and stability.

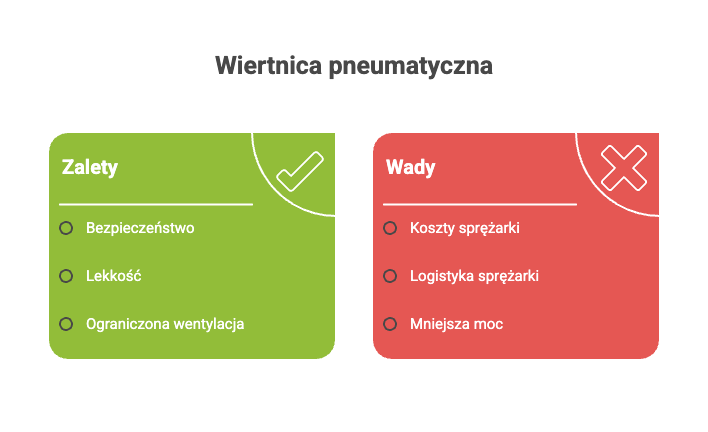

Pneumatics or lightness and precision - a drill rig for special tasks in difficult conditions

There are places and situations where neither mechanics nor hydraulics will do. High humidity, confined spaces, risk of gas explosions - this is where the pneumatic drill comes into play. Although it is sometimes overlooked in standard projects, in specialised environments such as mines, tunnels or wetlands - it is irreplaceable.

The pneumatic drive generates no sparks, requires no hydraulic oil and performs very well in restricted ventilation conditions. This makes it extremely safe where other technologies carry too much risk. Added to this is another important aspect - the weight of the entire rig. Pneumatic drill rigs are generally lighter, which makes them easier to transport and install in hard-to-reach places, such as on scaffolding or inside structures.

However, it is important to be aware that pneumatics require an independent source of compressed air - usually a compressor, which also has to be sized according to the capacity of the unit. This generates additional costs and requires separate logistics planning. However, if you are working in conditions where safety and lightness are more important than maximum power - pneumatics will be your ally.

The table doesn't lie - the real differences between hydraulic, mechanical and pneumatic drill rigs

When comparing these three types of rig, it is worth looking more broadly than just 'nominal power' or list price. Hydraulics offer the most power, precision and flexibility, but come with a higher investment cost and a greater need for service. Mechanical wins with simplicity, but loses in compact terrain and where accuracy matters. Pneumatics, on the other hand, is a specialised solution - not for everyone, but indispensable in a specific niche.

If you put these machines together in a table, the differences are striking:

- the hydraulic earth auger wins in terms of power and precision,

- the mechanical drill rig is the cheapest and most serviceable,

- the pneumatic drill is the safest and lightest.

These are not details that can be ignored. Each type of rig fits into a specific working model. There is no single 'better' solution - there is only one that realistically fits your needs, field conditions and job characteristics.

Working in the field? Find out which drill rig won't let you down in a particular scenario

In the end, it is the work scenario that should determine the choice of equipment. A hydraulic earth auger will be indispensable in heavy construction, foundation drilling, deep drilling, rocky drilling or in variable conditions. If you're working on one site for an extended period of time - with a large crew and strong facilities - a hydraulic will allow you to do the most, in the shortest amount of time.

A mechanical drilling rig will work well in the hands of local, point-to-point companies - such as fencing, landscaping or geotechnics. There you don't need full power, but availability and speed are important. You have the drive from the excavator, move and drill. No cables, no oil, no stress.

An air drill will be the choice when safety, mobility and working in confined spaces are priorities. This could be technical drilling in a building, working in a mine or installing underground utilities without access to heavy equipment. Seemingly a niche, but if you work there - it's the only option.

Read also:

- How to choose the right hydraulic earth auger for mini excavator?

- Drilling rigs for crawler excavators - what should you know before buying?

- Hydraulic earth auger for backhoe loader - what to look out for to get the right equipment?

- Proper operation of hydraulic earth augers

- Types of excavator drilling rigs - which ones to choose for specific tasks and materials?

- When to buy a new or used hydraulic earth auger - how to make the right decision?

- Hydraulic earth auger - when is it worth buying and when is it better to rent?

- The most common breakdowns and faults of hydraulic earth augers - how to solve them?

- Modern hydraulic earth augers - we present their applications in construction, agriculture and forestry

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous