If your excavator is dealing with steel structures, reinforced concrete or the dismantling of industrial infrastructure - a hammer alone is not enough. Cutters are attachments designed to cut metal accurately and efficiently. But before you decide to buy or rent one, it's worth knowing exactly what they are used for, how they work and what to look out for when choosing a model.

Not every excavator is the same - how do you choose shears for the weight and strength of your machine?

Choosing cutting shears for an excavator is not just a question of budget or type of work. One of the most common mistakes is not matching the weight and parameters of the attachment to the specific machine, which ends in unstable operation, arm overload or simply - another failure.

The shears must be compatible with the working weight of the excavator. If they are too heavy, they will upset the balance of the machine and affect the precision of manoeuvring - and therefore safety. If they are too light, there may not be enough force to cut harder structural components. The overall weight, the lifting force at a given overhang, the performance of the hydraulic system - all matter.

Remember, it's not just about 'will it work'. It's about whether it will work effectively, safely and for a long time. So it's always worth checking the exact specs of your machine and cross-referencing them with the technical documentation of the attachment - rather than relying solely on 'eye will fit'. This saves not only money, but also frustration on site.

Rebar, structures, scrap - what are cutting shears really for?

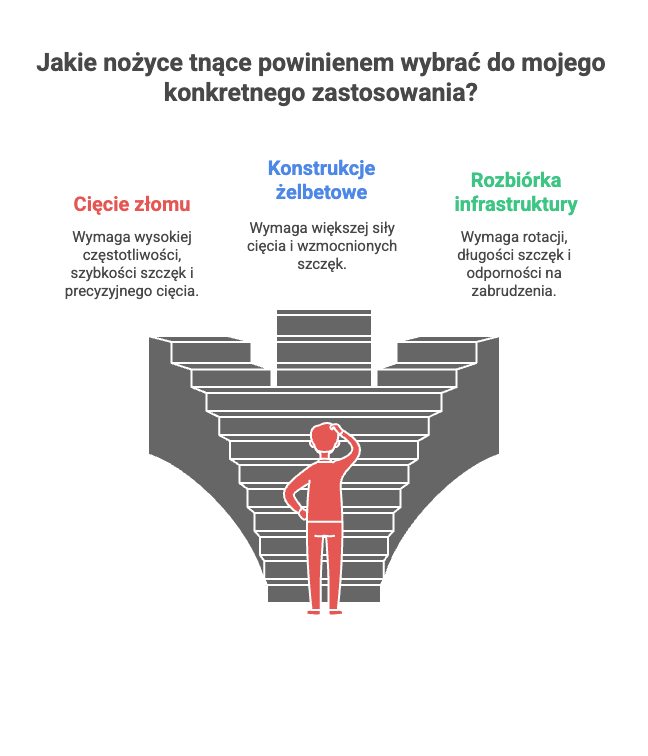

Surprisingly, many people think that all cutting shears are 'for demolition' and the differences are mainly a matter of brand. This is a gross oversimplification - because cutting shears are specialised equipment and each application requires a different approach.

If you're working on cutting scrap steel - high frequency, jaw speed and precision cutting are all important. In this case, scrap-type models with high clearance and aggressive edges work best. For reinforced concrete structures, on the other hand, you need attachments with higher cutting force and reinforced jaws that can handle rebar and concrete fragments.

The situation is slightly different when working with infrastructure, such as bridge or tunnel demolition. There, rotation, jaw length and dirt resistance are often more important than pure cutting power. Therefore, before you invest - consider what you will really be cutting. Not every "cut" means the same thing.

When is a basic model enough, and when do you reach for a shear for special tasks?

At first glance, many shear models look similar - solid steel, movable jaws, backhoe attachment. But the devil is in the detail. Basic shears will work well for lighter demolition jobs, but if you have intensive jobs in mind - you need higher-end equipment.

The entry-level versions have lower thrust, limited jaw travel and no full hydraulic rotation option, which limits their usefulness on more demanding sites. In many cases, it won't cope with thicker rebar, structural steel or cutting at difficult angles. And this means downtime and risk of damage.

The 'special task' models are in a different league - not only for their strength, but also for their durability and ergonomics. Hydraulic 360° rotation, hardened blades, quick-change cutting edges or reinforced handles - these are features that are not extras, but standard when you want productivity and no downtime. This is the point at which price translates directly into efficiency.

Cutting power, jaw opening, rotation - which parameters matter?

When choosing a cutter , it is worth stopping looking solely at the price or the declared weight. It is more important to look at the specific parameters - the ones that really make a difference to how the equipment performs in everyday work. Three things come to the fore: cutting power, maximum jaw opening and pivoting system.

Cutting force is the real ability of the tool to cope with certain materials - and it is worth checking this not only 'on paper', but also in the context of the excavator's hydraulic system. The opening of the jaws determines how large the workpieces can be covered - and it is this parameter that is important when demolishing larger beams, columns or sections of reinforced concrete.

Rotation (particularly 360° hydraulic rotation), on the other hand, is a function that significantly speeds up work and gives the operator freedom of action without having to constantly manoeuvre the entire excavator arm. It works faster, safer and with greater precision - which, especially in tight spaces or for selective cutting, can be invaluable.

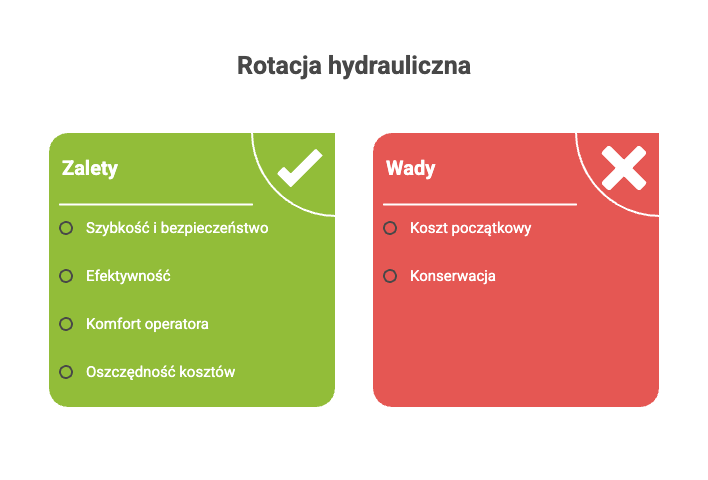

Does hydraulic rotation make a difference? Surprisingly much

To some, 360° rotation may seem like an add-on - something along the lines of 'it's nice to have, but you can get away with it'. Meanwhile, in practice, it is one of the most important parameters that affects real turnaround time and operator comfort.

Imagine a situation where you have to cut structural components at different angles, in hard-to-reach places. Without rotation - every angle change means manoeuvring the entire excavator, which is not only time-consuming but also tiresome for the machine. With hydraulic rotation, you change the position of the jaws without moving the arm - faster, safer, more efficient.

For the operator, this means less fatigue and more precision. For the business owner - less fuel, fewer errors, less structural damage that has to be corrected later. This is one of those parameters that quickly pays off in practice - not on paper.

How to avoid overheating and breakdown? A few words about pressure and flow

In day-to-day work, rarely does anyone stop to analyse the data on the rating plate. And yet it is the hydraulic parameters - such as operating pressure and flow - that are one of the main reasons for cutting shear failures. And unfortunately, these are mistakes that are not forgiving.

Every shear requires a specific pressure and flow range to operate at full capacity and - just as importantly - safely. Too low values mean poor cutting, unresponsive jaws, irritated operators and.... trying to 'crank up' the force. This is the easiest way to damage the cylinders and overheat the system.

Too much pressure, on the other hand , can destroy valves, tear seals and lead to uncontrolled oil leakage. The only thing is that this usually doesn't happen straight away. For a few hours, everything works, and then - suddenly - micro-leaks start, loss of power and, eventually, a complete shutdown of the gearbox. That's why it's important to match the shears not only to the excavator in terms of power and weight, but also to its hydraulics.

Is it better to rent or buy? And what if it doesn't fit the excavator?

This is a question most contractors ask themselves - especially on one-off jobs. And while buying always seems 'more cost-effective in the long run', it won' t always be the best choice - especially if you're not sure if the attachment will be used regularly.

Thereare several undeniable advantages to hiring a cutting shear. First of all - you can match a specific model to a specific job, without having to invest tens of thousands of zloty. Secondly - you do not have to worry about service, maintenance, transport or storage. And if a breakdown occurs - you get replacement equipment. This is a convenient solution, especially if you operate seasonally or in different locations.

Buying scissors, on the other hand, makes sense when the equipment will realistically work and generate profit. But beware - here the key is to match the model exactly to the excavator. If you don't check the parameters (weight, pressure, flow, type of handle), you could end up with shears that 'technically fit' but are useless in practice. And suddenly you find that the only thing they cut well is your budget.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous