Why is choosing the right hammer so important?

Selecting the right hydraulic breakers for excavators or mini excavators is a key element of efficient and safe demolition work. Whether you are demolishing reinforced concrete structures, crushing road surfaces or working in rocky terrain, the right hydraulic breaker allows for maximum efficiency, low fuel consumption and less wear and tear on the machine.

A hydraulic breaker is a heavy-duty attachment - it works in the toughest conditions, subjected to high loads, vibration andexternalinfluences. A poorly selected model can lead to accelerated wear of working components and even failure of the excavator. Therefore, the choice should not be random - it requires technical analysis and matching to the type of work being performed.

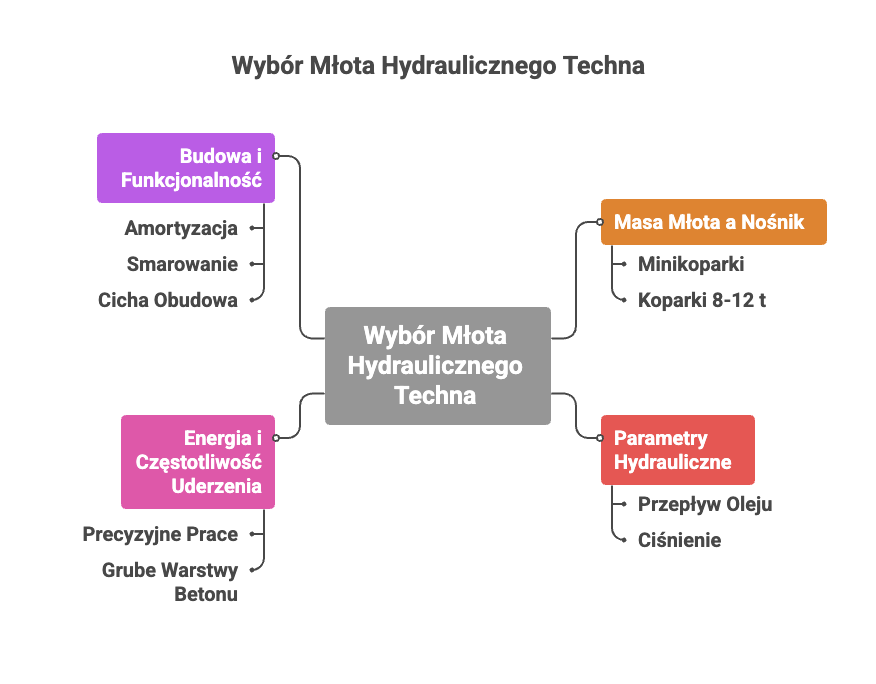

What to consider when selecting a hydraulic breaker?

Hammer weight vs. carrier

The choice starts with matching the weight of the hammer to the machine - a model that is too light will not be effective, and one that is too heavy may overload the excavator's arm. For example, for a 2.5t mini excavator, hammers up to 200-250kg are recommended. For 8-12 t excavators - attachments in the 500-800 kg range.

2 Hydraulic parameters

Each model requires a certain oil flow and pressure. If the parameters of the excavator are too low - the hammer will not reach the appropriate impact energy. On the other hand, too much pressure can lead to overheating or leakage of the system.

3 Impact energy and frequency

For high-precision work, such as façade forging, hammers with lower energy are sufficient. For thick layers of reinforced concrete - higher percussion force and weight are needed. Good hammers also have a vibration dampening system to protect the operator and the machine.

Design and functionality

It is advisable to choose hammers with internal cushioning, an automatic lubrication system, a reinforced housing and the ability to work vertically and horizontally. Versions with a low-noise housing will work well in cities and for night work.

Hydraulic breaker weight vs. carrier - a key parameter in selection

Choosing the right hydraulic breaker should always start with matching its weight to the parameters of the machine on which it will be mounted. This is one of the most important factors for operational safety, productivity and the life of both the hammer and the carrier itself. An inappropriate choice can lead to hydraulic system failure, damage to the excavator arm or even total immobilisation of the equipment.

A hammer that is too light - may not be effective enough, especially when working with hard materials. The operator will be forced to work longer, which increases fuel consumption and shortens the life of the attachment.

Too heavy a breaker - will overload the excavator arm, destabilise the machine and risk mechanical or hydraulic damage.

Below are examples of how to match the weight of the hammer to the carrier:

|

Excavator weight |

Recommended hammer weight |

Typical applications |

|

1-2 t |

80-150 kg |

light demolition work, backhoe excavation |

|

2,5-3,5 t |

150-250 kg |

concrete breaking, installation work |

|

5-6 t |

300-450 kg |

medium demolition, road works |

|

8-12 t |

500-800 kg |

crushing of foundations, demolition of buildings |

|

15-20 t |

1000-1500 kg |

rock breaking, industrial demolition |

|

20-30 t |

1500-2500 kg |

heavy demolition, quarry work |

Practical example: If you are working on a 2.8-tonne mini-excavator from Kubota or JCB, a hammer weighing around 200-250 kg, such as the TEHB250 model, would be the optimum choice. For a 10-tonne crawler excavator, such as a CAT 310, a TEHB700 or similar model - weighing around 700 kg - would be better.

It is worth remembering that the weight of the breaker is not everything - oil flow, operating pressure and impact frequency mustalso be taken into account and must be compatible with the hydraulic parameters of the excavator with demolitionbreaker .

Looking for robust attachments for construction equipment?Check out CAT construction machine breakers, JCB construction machine breakers, Kubota construction machine breakers and Bobcat construction machine breakers - durable, powerful and built to handle the toughest terrain.

Advantages of Techna hydraulic breakers

The Techna brand offers a wide range of hammers for excavators with demolition breakers from 1 to 30 tonnes. Features include:

- Robust construction, hardened working components

- High impact energy with low oil consumption

- Noise and vibration reduction system

- Versions with automatic lubrication and damping housing

Applications for Techna hammers

- Demolition work: removal of foundations, walls and ceilings

- Road works: breaking asphalt and concrete pavements

- Mining: crushing of rock in quarries and opencast mines

- Engineering: excavation of foundations, tunnels and underground installations

Comparative table of selected models

|

Model |

Hammer weight (kg) |

Carrier (t) |

Impact energy (J) |

Flow (l/min) |

Pressure (bar) |

|

THB150 |

150 |

1,5-3 |

250 |

25-45 |

90-120 |

|

THB350 |

290 |

3-5 |

500 |

35-65 |

100-140 |

|

THB600 |

460 |

5-8 |

780 |

45-90 |

110-160 |

|

THB1000 |

690 |

8-12 |

1050 |

55-100 |

130-170 |

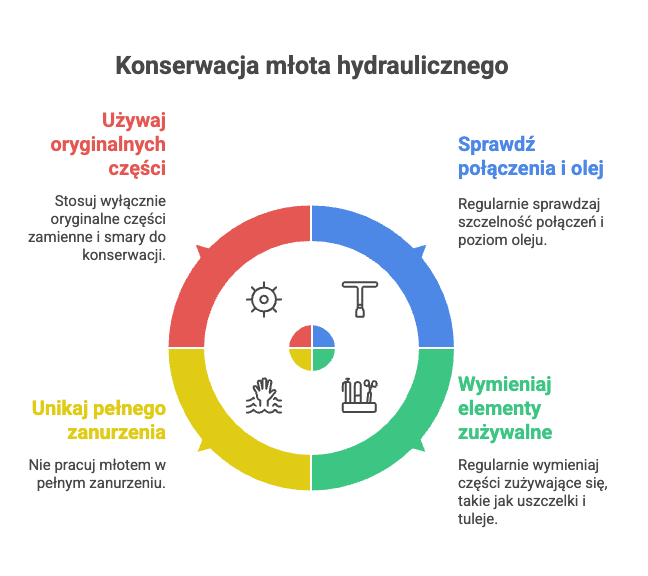

How do I look after my hydraulic hammer?

- Regularly check the tightness of the connections and the oil level

- Replace wear parts (seals, bushings)

- Do not operate the hammer in full immersion

- Use only original spare parts and lubricants

Summary

The right choice of hydraulic breaker is not only a question of efficiency, but also of safety and durability of the equipment. Techna Poland offers technical support, advice and a wide range of products ready for immediate delivery. Whether you are looking for a hammer for excavators with demolition breaker excavators, wheeled excavators or crawler excavators, you will find a solution to suit your needs.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- The wrong breaker is a big problem. How do you choose the right model for your excavator?

- How does a hydraulic breaker work?

- Hydraulic breakers for excavators with demolition breaker - what to look for when choosing one?

- Excavator demolition breaker operation - how to extend its life?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- The most common faults and failures of hydraulic hammers - how to solve them?

- Hydraulic breaker versus pneumatic breakers for excavators - differences, disadvantages, applications

- Hammer or hydraulic hammer breaker - which will work better on your excavator?

- Don't choose blindly - find out the real differences between hammer and vibratory hammer

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous