On today's construction sites, efficiency is the key to success. Construction companies, developers and machine operators are constantly looking for ways to reduce lead times, cut costs and optimise processes. One solution that effectively addresses these needs is screening buckets - attachments for excavators and mini excavators that transform a classic machine into a mobile material recycling centre.

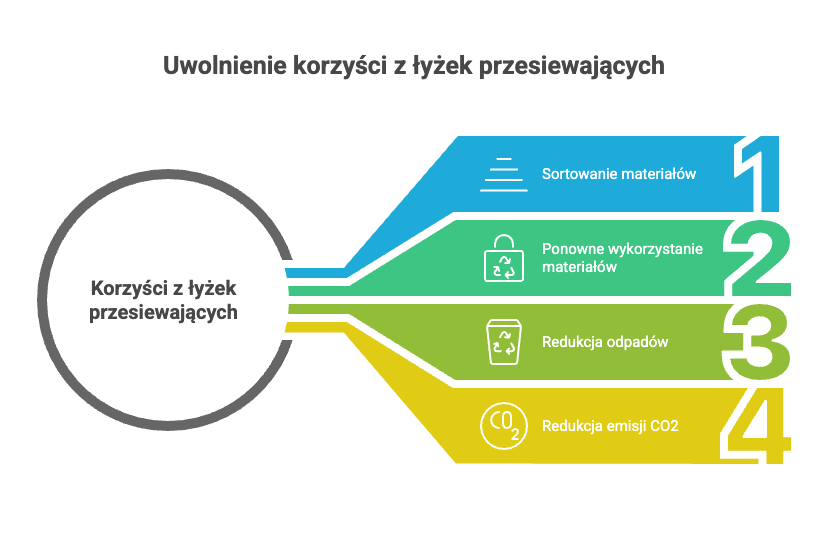

Advantages of using screening buckets

Screening buckets allow materials to be sorted directly at the work site. This removes the need to transport the excavated material to stationary screening buckets, resulting in significant savings in time and logistical costs.

Key benefits:

- sorting of different fractions of rubble, soil, sand, compost,

- possibility to reuse material without leaving the building site,

- reduction of waste and disposal costs,

- reduction in CO2 emissions due to reduced transport.

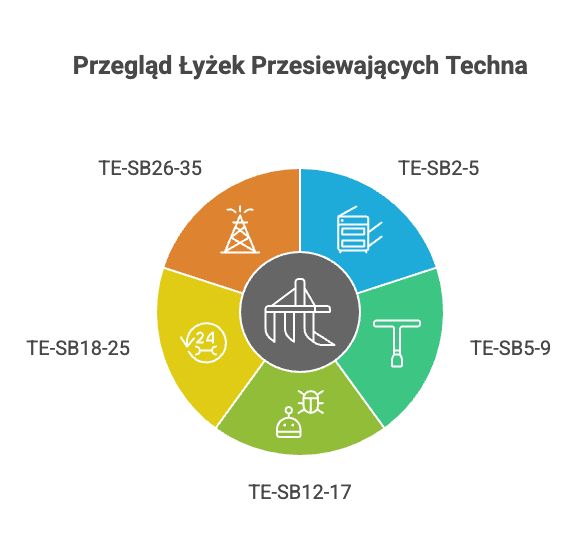

Screening buckets from Techna - the right bucket for every excavator and every job

In the Techna shop you will find a wide range of screening buckets to fit various construction machines - from mini excavators to heavy crawler excavators. Our buckets stand out for their robust construction, high performance and versatility in construction, recycling, agricultural and municipal applications. Below are the available models and examples of their use:

TE-SB2-5 (for excavators 2-5 t)

✔ Working volume: 0.03 m³

✔ Application:

- Ideal for clearing beaches of dirt and stones,

- Reclamation of domestic gardens,

- Material selection for small earthworks projects.

TE-SB5-9 (for excavators 5-9 tonnes)

✔ Working volume: 0.12 m³

✔ Application:

- Sorting of demolition debris on construction sites,

- Compost mixing on farms,

- Work on drainage ditches.

TE-SB12-17 (for excavators 12-17 tons)

✔ Working volume: 0.27 m³

✔ Application:

- Material selection in crushing plants,

- Separation of soil fractions in industrial land reclamation,

- Clean-up work on water channels.

TE-SB18-25 (for excavators 18-25 tons)

✔ Working volume: 0.63 m³

✔ Application:

- Separation of river stones for the construction of gabions,

- Clearing and site preparation for new developments,

- Large-scale recycling of construction materials.

TE-SB26-35 (for 26-35 tonne excavators)

✔ Working volume: 1.32 m³

✔ Application:

- Screening of large quantities of excavated material at mining and industrial sites,

- Sorting of heavy debris during demolition of large-scale structures,

- Use in construction waste sorting plants and municipal plants.

Each Techna bucket is designed for maximum operating efficiency and ease of use. Thanks to a precise selection of components and a wide range of machine fits, we are able to provide our customers with reliable attachments for the toughest sifting tasks.

Examples of application in practice

One construction company in the Mazovian Voivodship was implementing a road project where a large part of the site was covered with old gravel and contaminated soil. By using a screening bucket with a 14-tonne excavator, it was possible to recover more than 70% of the material, which after screening was used as the substructure for an internal road. Completion time was reduced by four days and the saving on disposal costs and the purchase of new aggregate was more than £15,000.

Cost comparison: with bucket vs. without bucket

|

Element |

Without screening bucket |

With screening bucket |

|

Rubble transport (t) |

30 |

5 |

|

Cost of disposal (PLN) |

6000 |

1000 |

|

Purchase of new aggregate |

8000 |

2000 |

|

Lead time (days) |

10 |

6 |

|

Labour cost (PLN) |

10000 |

6000 |

|

TOTAL |

24 000 zł |

9 000 zł |

As you can see, the investment in a screening bucket pays for itself after just a few projects, and additionally increases the efficiency of the team and enables the ecological management of construction waste.

Summary

Screening buckets are an example of a piece of equipment that has a real impact on the economy of work in the construction industry. Investing in such equipment is not only a step towards modernity, but also an expression of concern for the environment. If you are looking to optimise processes and reduce costs - it is worth considering the purchase of a screening unit mounted directly on your machine.

In addition, it is worth noting the variety of screening bucket models available from Techna. Customers can choose from buckets adapted for mini excavators, wheeled and crawler excavators as well as loaders. Depending on your needs and the specifics of your construction site, you can choose a model with the right type of screen - e.g. slotted or drum screen, which has a significant impact on the efficiency of material separation.

Our screening buckets are characterised by high durability, made of abrasion-resistant materials and designed for intensive use. Thanks to the use of state-of-the-art hydraulic components, they provide not only high performance but also energy efficiency, which translates into lower operating costs for the company.

All bucket models available at Techna are quality certified and compatible with popular machine brands such as JCB, CAT, Komatsu, Volvo and Kubota. What's more, we also offer after-sales support, spare parts availability and the possibility to modify for a specific project or type of material to be screened.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous