Selecting a hydraulic earth auger for mini excavator is not just a matter of matching the attachment to the machine - it is a decision that affects the work rate, operating costs and safety of the entire project. The wrong model can mean wasted time, increased fuel consumption and even the risk of damage to the equipment. If you want to avoid such problems, it is worth taking a moment to analyse the key parameters and match the machine to the type of soil, the planned tasks and the capabilities of your machine. In this guide, we will give you step-by-step advice on how to choose a hydraulic earth auger that will allow you to work efficiently and without downtime - whether you are operating in construction, agriculture or gardening.

Hydraulic earth auger for mini excavator - how to choose a model that will really make your work more efficient?

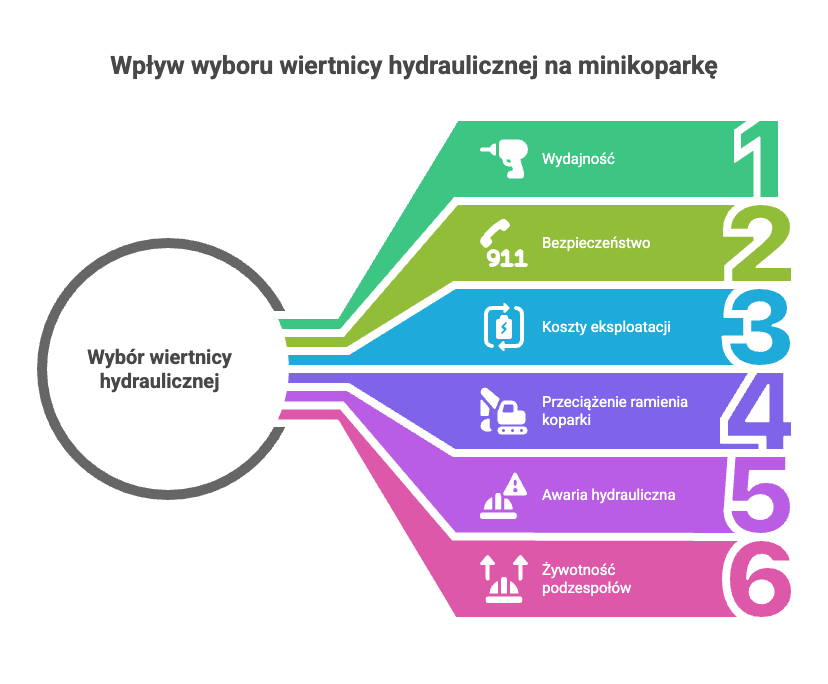

Choosing the right hydraulic earth auger for mini excavator is more than just buying an attachment - it's a decision that affects the productivity, safety and operating costs of the entire machine. The wrong model can result not only in wasted time or increased fuel consumption, but also in overloading the excavator arm, hydraulic system failures or reduced component life. That's why, before you click "buy", it's worth knowing which parameters are absolutely crucial and how to translate them into real working conditions in the field.

Weight of the mini-excavator and choice of drill rig

The first criterion is the weight of the mini excavator. This is what determines how much weight the drill rig can be safely attached while maintaining stability and full control of the machine. A drive unit that is too heavy can cause tipping, limit the precision of movements and increase the risk of damage to structural components. Conversely, a drill rig that is too light may not provide sufficient torque, making it difficult to drill in harder soils.

Example? If you have a 2.8t mini excavator, choosing a model designed for 4-6t machines would be a mistake - a better option would be the TEHB2000 or TEHB3000, which offer a compromise between weight and performance and are optimised for smaller carriers.

Manufacturers usually specify both the weight of the drive unit and the recommended weight range of the machine in the specification. Do not underestimate this data. Correctly selecting attachments for excavator weight means not only better productivity, but also extended life of the excavator arm and reduced risk of failure.

Hydraulic earth augers and flow and pressure parameters - how to match the attachment to the machine's capabilities?

A good match between drill rig and machine does not stop at weight - hydraulic parameters are equally important. Every excavator (even mini-excavators) has specific oil flow and operating pressure capabilities. If the drill rig demands more than your machine can provide, the effects will be immediately apparent - from a drop in speed to overloading and even permanent damage to the attachment.

For example, if your machine generates a flow rate of 40 l/min and a pressure of 180 bar, choose drill rigs with requirements within these limits - such as the TEHB3000. Avoid models designed for larger machines, which may require 70 l/min and 240 bar, as your hydraulic system simply won't 'handle' them.

It's also worth looking at the method of supply - most drill rigs require bidirectional oil flow (for left and right rotation). If your excavator with demolition breaker excavator is equipped with a one-way flow system (like under a hydraulic breaker), you may need to modify it or use an additional switch valve.

Bottom line: by knowing the flow and pressure parameters of your machine, you can consciously select attachments that will work efficiently without risk of overloading or damage. Always compare the drilling rig's catalogue data with your excavator's manual - this is the basis for an informed purchase.

Drilling diameter and depth - how do I choose a hydraulic earth auger for my intended tasks?

The next step when choosing a hydraulic earth auger is to determine what holes you will be drilling and under what conditions. Do you need drilling for fences, foundations or perhaps irrigation system installations? The working diameter range of drill rigs is very wide - the most popular values are 100-400 mm, but you will also find compact models on the market with diameters of 50-300 mm, which work well with smaller machines.

If you plan to drill deeper holes, you need to bear in mind that the standard auger length may not be enough. In this case, extensions would be a good solution to keep the drill stable and efficient even at greater depths. It is also important to choose a diameter so that the attachment does not overload the mini excavator' s hydraulic system and maintains adequate torque.

Ground type - why is it crucial when choosing a hydraulic earth auger?

Not every hydraulic earth auger will be equally effective on every terrain. The type of ground makes a huge difference to the effectiveness of the work and the durability of the attachment. For drilling in sand, clay or gravel, a standard auger will suffice. For rocks, hard clay soils or gravel-stone mixtures, it is advisable to choose attachments with replaceable forked teeth, which are much more resistant to abrasion.

For the toughest conditions - when it comes to drilling in solid rock - the best option will be rockworking heads designed for extreme loads. This will avoid premature wear on the attachment and downtime on the job. Matching the drill rig to the type of ground is not only a matter of efficiency, but also a matter of saving money - the right equipment will last much longer.

When choosing equipment for precision drilling, look no further than JCB's construction equipment drill rigs, which stand out for their reliability and high power. Equally prized are CAT excavator drill rigs, ideal for hard ground and heavy-duty work. For compact applications, a hydraulic earth auger for mini excavators from Kubota is perfect, and when working in confined spaces, a hydraulic earth auger for Bobcat will be indispensable.

Type of attachment and drive output - how do you ensure compatibility with your mini excavator?

The final element you need to look at when choosing a hydraulic earth auger is the attachment and drive output system. The most common mountings on the market are 65mm round, 75mm square and 110mm or 125mm hexagonal. Choosing the right mounting is of paramount importance, as it affects the stability of the work and eliminates the risk of backlash during drilling.

Make sure that the drill rig you choose will be fully compatible with your auger or that the manufacturer offers suitable adaptors. A lack of fit can not only reduce performance but also cause excessive wear on the power transmission components. If you're looking for a quick changeover, consider purchasing a mounting system that allows for quick attachment and removal, which will significantly reduce your set-up time.

Why does selection matter?

Choosing the right hydraulic earth auger is not just a question of price or appearance - it is first and foremost an investment in the performance, safety and longevity of your equipment. Drilling rigs need to work perfectly with the hydraulic system of your excavator or mini excavator with hydraulic earth auger, and any mismatch could end in a decrease in efficiency or, worse, failure.

Parameters such as operating pressure, oil flow or the weight of the attachment itself directly affect the work rate and operator comfort. If you choose a model unsuited to the capabilities of your machine, you could encounter stability problems and even risk damaging the hydraulic system. That's why it's so important to carefully analyse the specifications and match the drill rig to your needs and working conditions before you buy - so you can avoid costly surprises in the future.

Key specifications

Below you will find a comparison of three popular Techna hydraulic earth auger models, which differ in their working range and purpose. This overview is not just a dry table - if you know how to read it, you can easily decide which model is best suited to your tasks.

|

Model |

Machine weight (t) |

Torque (Nm) |

Operating pressure (bar) |

Oil flow (l/min) |

Drilling range (mm) |

|

TEHB2000 |

1-3 |

2000 |

60-240 |

20-70 |

50-300 |

|

TEHB3000 |

2-4.5 |

3000 |

70-240 |

25-70 |

100-400 |

|

TEHB3500 |

2.5-5 |

3500 |

70-240 |

25-75 |

100-400 |

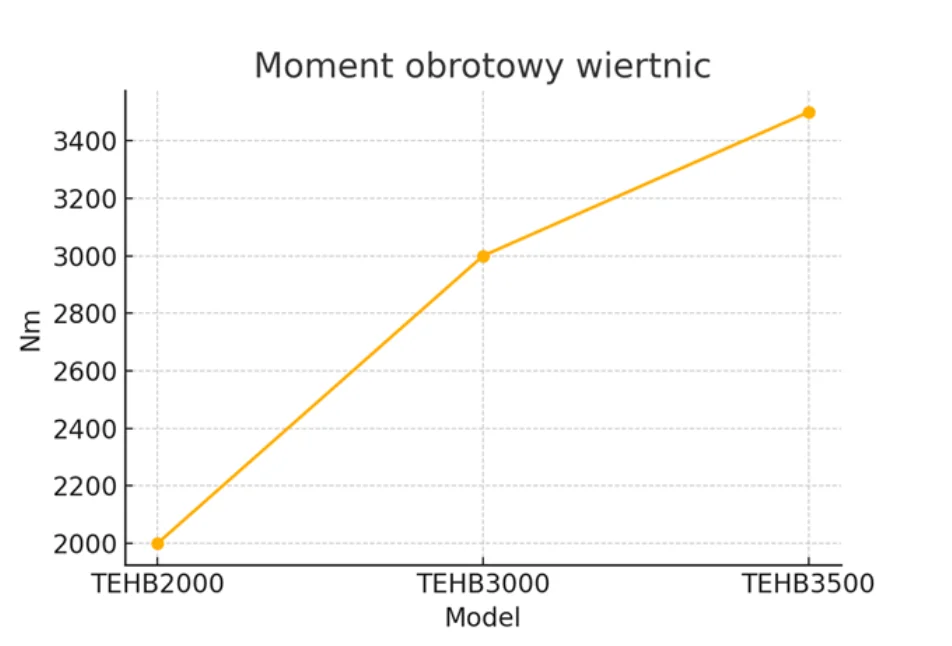

Torque comparison

The chart below shows the torque comparison for the three drill rig models:

Summary

Choosing the right hydraulic earth auger for mini excavator is a decision that can pay off very quickly - both in terms of increased productivity and reduced equipment failure rates. A well-chosen attachment also means greater operator comfort and the ability to complete tasks in less time, without unnecessary downtime.

Before purchasing, it is advisable to consult a specialist who can help you select a drill rig to suit the type of soil, the parameters of the machine and the planned work. At Techna Poland, you will find not only hydraulic earth augers for construction machines in many variants, but also professional advice and fast delivery times. Our offer includes, among others, hydraulic earth augers for excavators, as well as models adapted to lighter machines, which will prove useful in garden, construction and installation work.

Opt for equipment that will work as hard as you do - choose a drill rig to suit your needs and enjoy trouble-free operation for years to come.

Read also:

- Caterpillar excavator drilling rigs - what's worth knowing before you buy?

- Hydraulic earth auger for backhoe loader - what to look out for to get the right equipment?

- Proper operation of hydraulic earth augers

- Types of excavator drilling rigs - which ones to choose for specific tasks and materials?

- When to buy a new or used hydraulic earth auger - how to make the right decision?

- Hydraulic earth auger - when is it worth buying and when is it better to rent?

- Hydraulic earth augers for excavators - what to choose hydraulic, mechanical or pneumatic drive?

- The most common failures and faults of hydraulic earth augers - how to solve them?

- Modern hydraulic earth augers - we present their applications in construction, agriculture and forestry

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous