The crushing jaw is a tool that has completely changed the way demolition and recycling of construction materials is carried out. It allows you to crush concrete, asphalt or stone directly on site, without the need for large stationary crushers. If you want to learn how the concrete pulverizer for excavators works, what it consists of and where it is used, read this article to the end - you will find everything you need to know about this indispensable attachment for excavators.

What is a demolition jaw for excavators?

The demolition jaw is one of the most important tools for efficiently processing construction materials directly on site. Its design is designed to maximise the potential of the excavator's hydraulic system, while reducing the need for large, stationary crushers. This allows the operator to crush concrete, brick, asphalt or even stone directly on the job site, significantly reducing lead times and logistics costs. The unit therefore provides a mobile, highly efficient solution for companies specialising in demolition, recycling or ground preparation for developments.

In practice, the crushing jaw works on the principle of compressing material between two jaws - a fixed one and a moving one. The moving part is driven by hydraulic force, which comes from the excavator's pump. It is this element that generates the enormous working pressure, often in excess of 200 bar, which allows hard concrete structures to be crushed with an ease that other equipment cannot achieve. It is also worth mentioning that, in many cases, the crushing jaws are used in parallel with hydraulic breakers for excavators, mini excavators or backhoe loaders, creating a set-up that works well in the various stages of demolition - from the initial breaking of the structure to the final processing of the material.

How is the concrete pulveriser for excavators constructed?

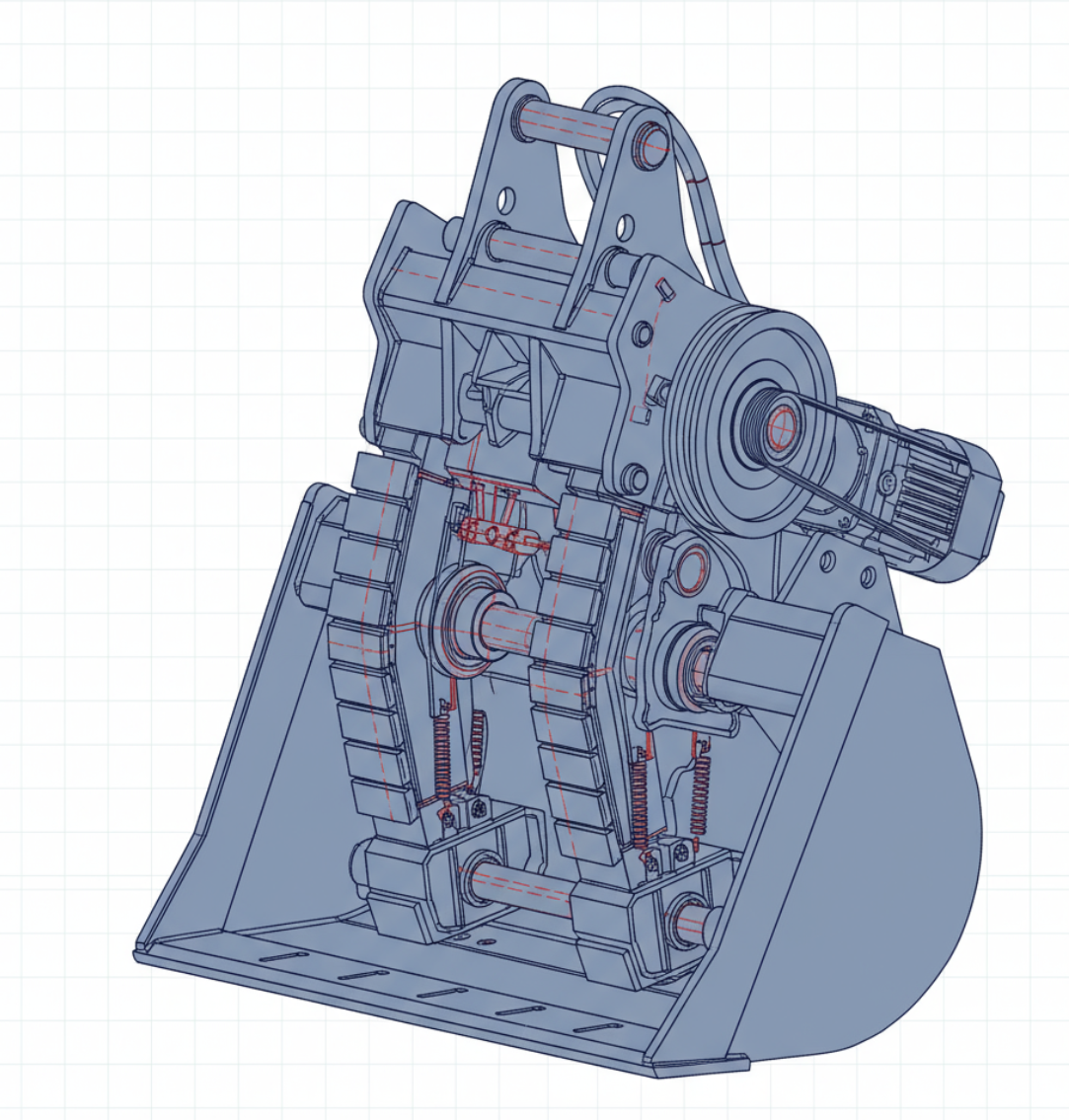

The construction of a crushing jaw is surprisingly complex, although at first glance it appears to be a simple device. Inside it lies a combination of mechanical precision, robust materials and high-powered hydraulic systems. At the heart of the design is the frame, a body made of hardened HARDOX steel. It is this that absorbs most of the loads generated during operation and provides a solid base for the other parts. Attached to the frame is the fixed jaw, which acts as a stationary 'anvil', and the movable jaw, which is responsible for the actual crushing process through a repetitive swinging motion.

An eccentric shaft connected to a hydraulic system, which converts the energy of the high-pressure oil into mechanical force, is responsible for generating the movement. High-performance ball bearings and safety valves protect the system from overload, while the flywheel stabilises the pace by storing kinetic energy. Also worth mentioning is the crushing chamber, which is shaped to taper downwards - it is this that ensures the natural flow of the excavated material. This is complemented by protective guards and side plates, which increase work safety and reduce wear on the working surfaces.

This design makes the concrete pulverizer an extremely efficient and durable attachment for excavators that can easily handle even the hardest material. Thanks to its design and hydraulic power supply, this attachment for excavators allows you to significantly increase the machine's range of capabilities, making it a versatile tool for demolition and recycling work.

How does the concrete pulveriser for excavators work?

The principle of the crushing jaw is simple in theory, but in practice it requires precise synchronisation of the hydraulic movements. The device works in a cycle that consists of several repetitive phases. The first phase is the opening of the jaws and the loading of the material - at this point, the working space enlarges, allowing the gravity fall of the rubble, concrete or stone. The moving jaw then begins to close, initiating the crushing process. This is the moment when hydraulic energy is converted into compression force and the material is gripped and pushed towards the bottom of the chamber.

In the next stage, the actual crushing takes place, which is the moment when the crushing force reaches its maximum - depending on the jaw class, this can be from 75 to as much as 250 tonnes. The material is then compressed, sheared and crushed until it is crushed. Once the point of maximum pressure has been reached, the system proceeds to the pushing and unloading phase, in which the crushed pieces fall out through the lower discharge opening. The entire cycle closes with a return phase, in which the hydraulics return to the neutral position, preparing the jaw for the next shred.

It is worth knowing that the number of working cycles can range from 20 to 120 per minute and the capacity - depending on the class of machine and type of material - can reach up to 400 tonnes per hour. Such parameters make the crushing jaw an invaluable support on construction sites, especially where hydraulic breakers hammers for excavators are also used. In duo, these two tools make it possible to carry out the full demolition process - from breaking to crushing and segregation.

Where are the crushing jaws used?

It is difficult to imagine modern demolition work today without a crushing jaw. This equipment is used in a wide range of areas - from the demolition of concrete and steel structures, to the recycling of construction waste, to the production of aggregate in quarries. It is used both in large infrastructure projects and in smaller road or urban works where precision and minimal noise levels are important. Compared to conventional hydraulic breakers for excavators with demolition breaker for backhoe loaders, the crushing jaw operates more quietly and in a more controlled manner, thus reducing nuisance to the environment.

The device also proves its worth in rubble recycling, where it allows the shredded materials to be reused in the construction process. Thanks to the cutting blades, the jaws can also separate concrete from rebar, making the segregation of raw materials much easier. They are also used in rescue work, e.g. in the aftermath of construction disasters, where fast reaction and precise action are important. In short, concrete pulverizers for excavators are not only a demolition tool, but also a versatile piece of excavator equipment that enhances the capabilities of the excavator in almost any type of field work.

FAQ

Does a concrete pulverizer for excavator fit every excavator?

Not every crushing jaw will be compatible with any excavator. Each model requires the correct machine capacity, hydraulic performance and a special mounting system tailored to the specific excavator model. Before purchasing, make sure that the specifications of the machine match the capabilities of the excavator.

What materials can be crushed with a crushing jaw?

Crusher jaws can cope with a wide range of materials, mainly concrete, brick, asphalt and natural stone. Some designs also allow you to crush steel or reinforced concrete elements, and with some models you can cut and separate reinforcement from concrete.

What is the maintenance of the crushing jaw?

The basis is regular lubrication of the moving points (bearings, eccentric shaft, jaw hinges) and checking the condition of the blades and working elements. It is also important to periodically replace seals and hydraulic quick couplings to prevent oil leaks.

How long does a crushing jaw last under intensive use?

The total service life depends on the quality of manufacture, the type of material processed, regular maintenance and use. High-quality jaws made of HARDOX can operate without failure for several years even under harsh conditions, provided they are regularly serviced.

Does the crushing jaw require additional operating authorisation?

A qualification as an excavator operator with a licence for equipment with hydraulic attachments for excavators is usually sufficient to operate a crushing jaw. However, training in the use of the specific tool and safety rules is recommended.

What parameters should I consider when choosing a crushing jaw?

The most important are the weight of the jaw, the capacity (tonnes per hour), the maximum operating pressure, the width of the chamber inlet, the length of the jaws and how they are mounted to the excavator arm. It is also worth noting the availability of spare parts and ease of servicing.

Can a hydraulic breaker and crusher jaw be used at the same time?

Yes, but not at the same time - these tools complement each other at different stages of demolition. First, the hydraulic hammer breaks up the larger pieces, then the crushing jaw crushes and shreds the material to the desired fraction.

What are the most common failures of the crushing jaw?

Common failures include damage to the eccentric shaft, leaks in the hydraulic system, worn working blades and loose mountings. Regular inspection and replacement of worn parts minimises the risk of failure.

Are the breaker jaws noisy during operation?

Compared to classic demolition hammers, the demolition jaws are relatively quiet. Thanks to the vibration and force damping system, the operation of the tool is less disruptive to the surroundings, which is important in urban developments and night work.

Are spare parts and service available for the crushing jaw?

Reputable manufacturers offer a wide range of spare parts - from working jaws to bushings to complete gasket sets. Authorised and mobile services often allow on-site repairs, minimising machine downtime.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous