Demolition work requires precision, experience and well-chosen equipment. It is the attachments for excavators that determine the speed, efficiency and safety of the entire process - from the first blow of the hammer to the sorting of the debris. In this article, you will learn how to choose the right demolition tools, learn about their types and uses, and see why the right choice of attachments can significantly speed up any project.

How do I choose the right demolition attachments?

Choosing the right attachments for demolition and demolition work is crucial to productivity and safety. It determines how quickly and accurately the work will proceed and how long the equipment will last. It is therefore advisable to match the tools well to the type of construction, the weight of the excavator and the terrain conditions. The right attachments for excavators not only increase the efficiency of operations, but also reduce wear and tear on the machinery and the cost of the overall project.

Analysis of working conditions

Before deciding on a particular model, start with an analysis of the working conditions - find out what kind of material you will be working with, where the project is located and what range of activities you are planning. A different attachment will be suitable for demolition work in a city centre, and a different one for heavy work in a quarry.

Selecting attachments for excavator weight

The next step is to select the attachment for excavator weight. Remember that an attachment that is too heavy can disturb the stability of the machine and lead to damage to the hydraulics. Ideally, the weight of the attachment should be around 10-15% of the weight of the entire excavator - this ensures optimum performance and safety.

Selecting the hydraulic parameters

Next, pay attention to the hydraulic parameters. Every attachment - hammers, jaws or grabs - works on the basis of oil flow and pressure. If the hydraulic system of the excavator is not compatible with the attachment, overheating or loss of power can occur.

Material analysis

Also, don't forget the type of material you plan to crush. For concrete, hammers with an energy of 1,500-3,000 J are sufficient, while for reinforced reinforced concrete, equipment with much more power is required. Choosing the right tool will not only speed up your work, but also avoid unnecessary wear and tear on your equipment.

Analysis of installation options

Finally, check the ease of installation and service availability. In intensive demolition work, quick replacement of components or access to spare parts is a huge advantage. A well-chosen attachment is an investment that will realistically reduce lead times and downtime.

Consideration of budget and performance

It is also worth considering budget and productivity at the planning stage. The purchase or rental of equipment should be tailored to the scale of the project - the most advanced model will not always be the best choice. Sometimes it is better to opt for robust, simpler equipment with lower running costs, especially for smaller projects.

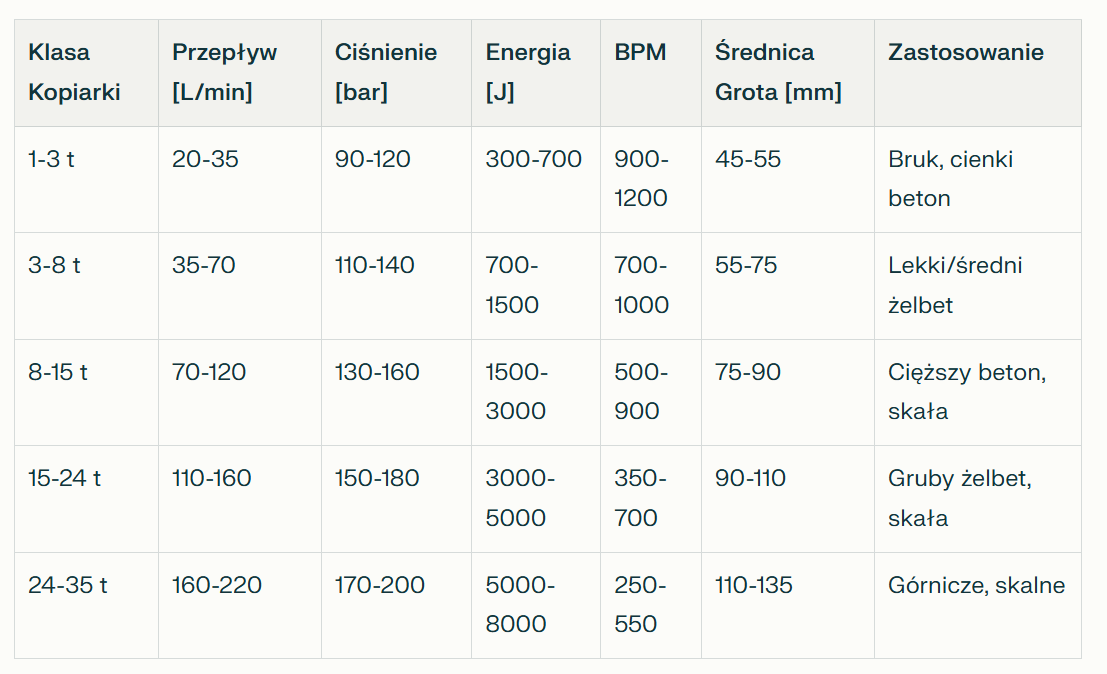

Attachment selection table by excavator class

Types of demolition attachments - what will you need?

Among the tools available, hydraulic breakers for excavators are the most versatile and the most popular choice. They work well for both primary and secondary demolition - they can crush concrete, asphalt or rock. Their performance depends on the percussion energy and the frequency of the blows, so higher-performance models are great for working in hard ground or on large structures. For smaller machines - such as mini excavators - there are compact, lower-energy versions that make it easier to work precisely in confined spaces.

On the other hand, concrete pulverisers for excavators and cutting & crushing shears are tools that allow you to work selectively - cutting steel and crushing concrete at the same time. This allows you to separate materials already during demolition, which speeds up the segregation process considerably. Steel shears are great for dismantling halls or bridges, while cutting & crushing shear models reduce dust and make work in city centres easier.

Demolition grabs are also increasingly in use, allowing not only the removal of structural fragments, but also the sorting and transport of heavy components. Hydraulic 360° rotation ensures full control of the movement, while steel structural components guarantee durability and safety even under heavy loads.

Working safety with demolition and demolition attachments - your priority when choosing!

During demolition, the risk of accidents is extremely high, so the safety of the operator and the entire team must be an absolute priority. Any work with heavy equipment requires the right qualifications and regular health and safety training. The operator should be familiar with the specifics of the equipment being used - from the principles of the hydraulic system to checking pressure or wear on working components. Before the start of the working day, a thorough technical inspection of the attachment is essential - checking for leaks, leaks, warning signals and ground stability.

The use of personal protective equipment is also important. Helmet, goggles, gloves, footwear with reinforced soles and ear defenders are an absolute minimum. In the case of intense dust, it is advisable to use filter masks and, when working at height, safety harnesses. Remember, too, that it is strictly forbidden for third parties to be within the operating range of equipment. Every machine must have a valid inspection and work should be supervised by a qualified specialist. By following these rules, you will avoid health-threatening situations and minimise the risk of equipment failure.

How can the right equipment make demolition work easier and faster?

The right attachments for excavators can dramatically change the pace of a project. Modern hydraulic hammers, shears or multifunctional jaws not only increase precision, but also reduce the time needed to dismantle a structure. In practice, this means that one excavator with well-fitted attachments can perform tasks that only a few years ago required several machines. Importantly, modern solutions are equipped with vibration dampening and noise reduction systems - a huge benefit, especially for urban demolition.

The ease of changing working tools is also not insignificant. Hydraulic quick-release couplings allow the attachments to be changed without leaving the cab, so that work proceeds smoothly and without downtime. Suitably sized crushing jaws or sorting grippers make it possible to crush and separate debris at the same time, eliminating the need for additional machinery. All this translates into real savings - both in terms of time and operating costs. As a result, you gain more control over the project, shorter lead times and higher team productivity.

FAQ

How do I choose a hydraulic breaker for excavators?

Hammer selection depends on the weight of the excavator with demolition breaker and the type of material you plan to crush. Typically, the weight of the breaker should not exceed 10-15% of the machine weight to maintain stability and performance.

What is the difference between concrete crushing jaws and cutting & crushing shears?

Crushing jaws are mainly used for crushing concrete, while cutting & crushing shears are used for cutting steel and metal structures. In practice, they are often used together to crush and separate materials at the same time.

Are demolition grabs suitable for sorting rubble?

Yes, demolition grabs make it possible not only to move heavy components, but also to accurately sort the material after demolition. Their 360° hydraulic rotation facilitates precise handling in difficult conditions.

How often should the demolition attachments be serviced?

Maintenance is recommended to be carried out every few months or after a certain number of operating hours, as recommended by the manufacturer. Regular servicing prolongs the life of the equipment and prevents breakdowns.

Is different equipment needed for demolition in a city than in a quarry?

Yes, in cities quieter, less vibrating equipment is used to reduce noise and vibration. In quarries, it is mainly the power and durability of the equipment that matters.

Can attachments for excavators be rented rather than bought?

Yes, many companies offer to rent hammers, jaws and grabs for short or longer periods. This is a good solution for one-off jobs or for testing new models.

How do I check the compatibility of an attachment with an excavator?

Compare the hydraulic parameters - oil flow, pressure and operating weight - with the excavator's specifications. If in doubt, it is best to consult the equipment manufacturer or service centre.

What should I do if an attachment overheats during operation?

Overheating is most often a sign of incorrect pressure or insufficient hydraulic oil flow. In this situation, stop work immediately and check the hydraulic system.

How do I increase the service life of my demolition attachments?

The most important thing is to regularly lubricate, clean and inspect the working components. Also avoid overloading the equipment - working within the manufacturer's parameters is the key to a long service life.

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous