Hydraulic earth augers for excavators are some of the most commonly used tools for earthworks, installation and geotechnical work. Thanks to their power, versatility and ability to work in difficult terrain, they are indispensable in many industries - from construction and agriculture to geology and heavy industry. Choosing the right hydraulic earth auger for excavator is not a "snapshot" decision - not only the speed and precision of the work depends on it, but also the operating costs and the ability to complete jobs. If you want to drill into hard ground, bore holes for piles, foundations or photovoltaic installations, a good choice of attachment will translate into real profit and lower equipment failure rates.

What are hydraulic earth augers for excavators?

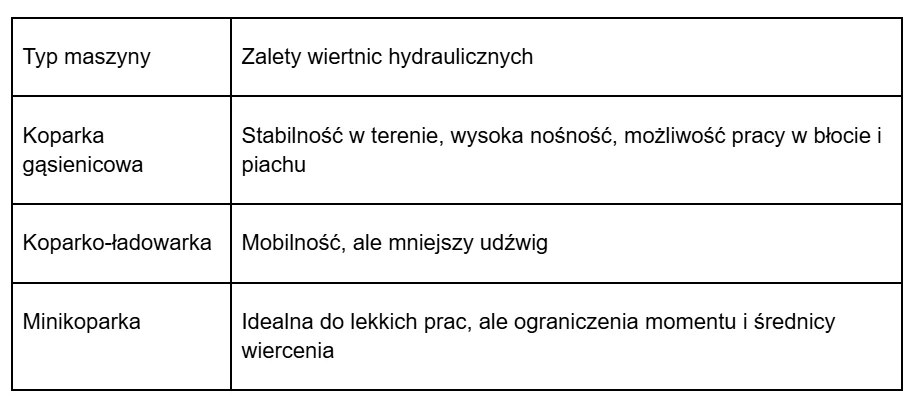

Hydraulic earth augers for crawler excavators are specialised attachments that are mounted on the arm of the machine to drill holes in the ground of various diameters and depths. At their heart is a planetary gear driven by the excavator's hydraulic system, which allows for very high torque - crucial when working in difficult terrain.

Thanks to this design, the drill can cope with soft soils and sands as well as gravelly or rocky ground. This makes it indispensable in the construction industry, geotechnical fields, installation of fences, foundations or drilling for photovoltaic installations. Models in the range of hydraulic earth augers for excavators, such as the TEHB8000 or TEHB20000, allow boreholes as large as 1,200 mm in diameter.

Importantly, the crawler excavator provides stability and mobility in areas where other machines might not be able to cope. The wide crawler tracks distribute pressure on the ground, minimising the risk of bogging down, and the machine's high weight increases downforce when drilling. This makes this type of drill rig the number one choice for companies carrying out demanding field work.

Operators who value versatility are increasingly opting for hydraulic earth augers for JCB excavators, which can be fitted to a variety of auger bit types. For heavier work, CAT hydraulic earth augers for backhoe loaders are recommended for stable and efficient operation. A Kubota forging drill is also available, and for owners of compact machines, a hydraulic earth auger for mini excavators with hydraulic earth auger for mini excavators from Bobcat is an ideal choice.

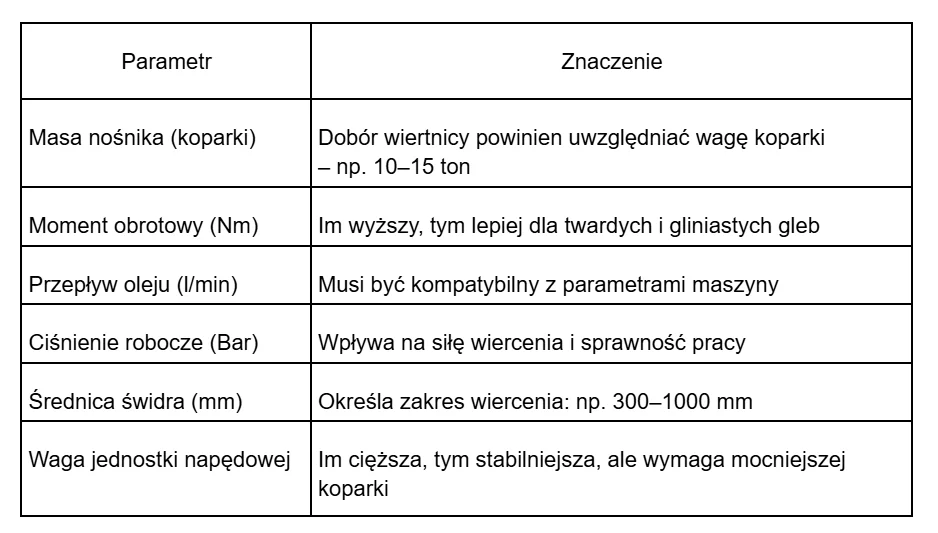

Key specifications for crawler excavator drill rigs - what to look out for?

Selecting a drill rig for a crawler excavator is not just a question of brand or price - it is crucial to match the technical parameters to the capabilities of the carrier and the nature of the work. Below, we outline the key elements that determine drilling efficiency, equipment durability and operator safety.

- Carrier (excavator) weight

- The weight of the excavator has a direct impact on which drill rig models can be fitted.

- For example, machines weighing 10-15 tonnes are best suited to the TEHB15000 series, which offer high torque and high stability during operation.

- A carrier that is too light can lead to tipping and loss of drilling efficiency.

- Torque (Nm)

- The higher the torque, the better the performance of the drill rig in hard and clay soils.

- For demanding geotechnical drilling, drill rigs reaching more than 20 000 Nm, such as the TEHB20000, are recommended.

- It is worth remembering that high torque means faster operation and less strain on the excavator's hydraulic system.

- Oil flow rate (l/min)

- It must be perfectly compatible with the parameters of the excavator - too low a flow will limit performance, and too high a flow can damage the system.

- The models available in the hydraulic earth auger category have a wide range of flow matching, making it easy to configure with different carriers.

- Working pressure (Bar)

- Responsible for downforce and drilling efficiency.

- Drills operating between 170-240 bar allow efficient operation in most ground conditions.

- Auger diameter (mm)

- This is the parameter that determines the drilling range - for tracked excavators, diameters from 300 to 1000 mm are typical.

- The choice depends on the application - from tree planting to foundations to drilling for piles.

- Weight of the drive unit

- A heavier unit provides better stability during operation, but requires a stronger carrier.

- TEHB series drills are designed to optimally balance weight with performance, resulting in longer equipment life.

Key specifications you need to know

How to choose a drill rig for a crawler excavator depending on the type of work?

Choosing the right drill rig for a crawler excavator largely depends on the conditions and tasks it will be used for. Here are examples of applications with recommendations from Techna Poland.

Geotechnical work

- Require drill rigs with high torque and robust construction to cope with drilling in hard, clay and mixed soils.

- Models from the hydraulic earth auger category are well suited to this type of work, providing stability and high power.

Road construction

- Drill rigs designed for drilling holes for poles, energy barriers or road signs are ideal.

The compact but powerful models available in the hydraulic earth auger for backhoe loaders section are particularly suited to this segment and enable many holes to be drilled quickly in a short space of time.

Conclusion - how to buy a well-chosen drill rig for crawler excavators?

Buying a drill rig for a crawler excavator is an investment that should be well thought out. It is crucial to match the rignot only to the type of work planned, but also to the technical parameters of the carrier. The right choice of drill rig can increase productivity, reduce operating costs and cope with even the most demanding field tasks. Aspects such as the weight of the carrier, torque, operating pressure, oil flow or auger diameter are all worth considering - each of which has an impact on the drilling efficiency and durability of the equipment. A well-fitted drill rig is a guarantee that work will go quickly, efficiently and without downtime.

Techna brand drill rigs are designed for intensive, professional use - with full service support and fast delivery times.

When is a crawler excavator the best choice?

A crawler excavator is a machine that performs in all terrain conditions - from sandy, muddy areas to sandy ground. Thanks to its wide tracks, it provides exceptional stability, which is key when drilling deep or in difficult ground. Its high load capacity enables it to work with high-torque drills, which translates into easy drilling even in hard and clay soils. The machine's heavier weight and even pressure distribution make it possible to drill for piles, poles or deepwater installations in places where other machines would have difficulty reaching. With models designed for excavators weighing 10-20 tonnes, drilling diameters from 300 mm to as much as 1,200 mm is possible, with torque up to 20,000 Nm.

Using drill rigs for crawler excavators in practice - case studies from our company

In order to see how crawler excavator drill rigs perform under real-world conditions, it is worth taking a look at specific realisations from our customers.

Example 1 - Drilling for foundation piles (geotechnics)

A client from the Mazowieckie Voivodeship used the TEHB15000 to drill a series of boreholes for piles in extremely demanding ground conditions - on clay-sandy subsoil, which often slows down traditional methods. The drill rig was mounted on a 13-tonne crawler excavator, ensuring stability and precision during drilling. More than 40 boreholes with a diameter of 600 mm and a depth of 3 m were drilled in a single day, a much better result than with classic techniques. The result? Faster completion, lower costs and higher productivity.

Example 2 - Drilling deep wells

A company in the Podlasie region invested in a TEHB8000 model with a view to expanding its offerings to include well installation. The rig operates on a 9-tonne carrier and its capabilities allow it to drill wells up to 10m deep using a 300mm diameter auger. Operators praise the equipment for its reliability, low oil consumption and repeatable drilling quality, resulting in more jobs and customer satisfaction.

Bottom line - when is it worth betting on a crawler excavator?

If you are working on projects with a large drilling scope, in difficult ground conditions, where machine stability is key, a crawler excavator with a hydraulic earth auger is an unbeatable solution. By choosing this combination:

- you reduce the time it takes to complete tasks,

- you provide greater flexibility in drilling depth and diameter,

- you can work in places that are inaccessible to other machines.

For professionals who cannot afford to compromise, this is the choice that guarantees performance, safety and reliability.

If you're not sure which drill rig fits your machine - contact Techna Advisors. We will select the optimal solution for your needs!

Read also:

- How to choose the right hydraulic earth auger for mini excavator?

- Hydraulic earth auger for backhoe loader - what to look out for to get the right equipment?

- Proper operation of hydraulic earth augers

- Types of drill rigs for excavators - which to choose for specific tasks and materials?

- When to buy a new or used hydraulic earth auger - how to make the right decision?

- Hydraulic earth auger - when is it worth buying and when is it better to rent?

- Hydraulic earth augers for excavators - what to choose hydraulic, mechanical or pneumatic drive?

- The most common failures and faults of hydraulic earth augers - how to solve them?

- Modern hydraulic earth augers - we present their applications in construction, agriculture and forestry

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous