Has your hydraulic hammer stopped working as it should? Or maybe something is knocking, but not where it needs to be? Before you dismantle half your machine or call for service, check out what could really be the cause. In this guide, you'll find specific fault scenarios ranging from a lack of hammering to performance drops to gas problems and leaks.

Is there something wrong with your hammer? Start with a basic check before you call for service

Before you conclude that your hydraulic breaker is up for a major overhaul, it's a good idea to start with some simple and quick diagnostics. Not everything that looks like a failure actually is. Sometimes the problem is too low oil or nitrogen pressure, a loose hydraulic connection or simply a dirty mainsail.

A good habit is to do a daily visual check before starting work. Check that there are no cracks in the housing, that the mainsail is clean and that the hoses are not leaking. Then run the machine for a few moments - if the hammer doesn't strike evenly, you hear unnatural sounds or there is uneven operation, it's a sign that something is worth checking deeper.

Remember that reacting quickly to the first symptoms can save you from big costs. Failure to carry out a basic pre-start check is one of the most common mistakes that users of hydraulic hammers make. Many faults are due to things that can be picked up in literally minutes.

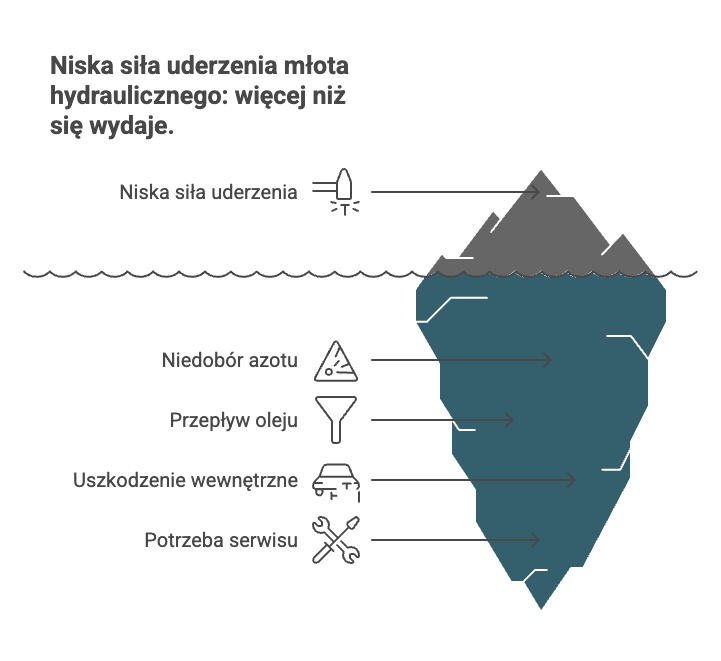

Does the hammer strike too weakly or not at all? See where the problem most often lies

When the impact force drops or disappears altogether, this does not always indicate a serious failure. Low impact force is often the result of a shortage of nitrogen in the gas accumulator. In many cases, all that is needed is to top up its level and set the correct pressure according to the technical documentation.

Another reason may be inadequate hydraulic oil flow, especially if the machine system is not calibrated correctly. For the operator, this is a signal to look at the valve settings and filter the oil if it has not been changed for a long time. In extreme cases, where the strokes are completely absent, the problem may lie in piston or cylinder damage.

If you have eliminated the underlying causes and the equipment is still not working properly, it is time to have it diagnosed by a specialist service. This is especially important for models running under heavy load. Don't underestimate this point - continued use can lead to permanent internal damage.

Hammer performance dropping day by day? These three things could be to blame

If you have the feeling that your hammer was running at full steam not long ago and is now slowly "going out", pay attention to the operating components, oil condition and hoses. These are the most common trouble spots that cause a drop in efficiency.

The mainsail, seals or oil filter are parts that wear out with every project. If you work intensively, replacements should be done regularly, preferably every few hundred hours of operation. Otherwise you risk not only poorer efficiency, but also more serious damage to the system.

Added to this is contaminated hydraulic oil, which can cause micro-breaks and even lead to valve failure. And don't forget about quick couplings and hoses - even minor leaks can result in pressure loss and a drop in power.

For professionals who value durability and power, a CAT demolition hammer or JCB demolition hammer would be the ideal choice. Also check out Kubota demolition hammers and Bobcat demolition hammers - they can handle even the toughest material perfectly.

Does the hammer work, but "strangely"? Learn the typical symptoms of irregular operation

Irregular impacts, unexpected stoppages or strange vibrations? This is no coincidence. Such symptoms are usually associated with nitrogen pressure problems, a clogged filter or faulty valves. Don't wait for the unit to refuse to operate - act at the first sign of instability.

Vibration is often the result of loose mounts, worn damping components or incorrect gas pressure settings. Ignored, they can quickly lead to damage to the work tool and even the housing. If you've noticed uneven impacts or sounds that weren't there before, it's a signal that something needs to be looked over.

Sometimes cleaning the oil system and correcting the settings will be enough to get the hammer back in shape. In more advanced cases, service assistance will be required. But one thing is certain - irregularities always serve something. And they always herald something more.

Oil where it shouldn't be? How do you deal with leaks and spills?

Hydraulic oil leaks are one of the most common and most ignored problems. Seemingly no big deal, but over time they cause serious pressure drops and significantly reduce efficiency. Added to this is the risk of contaminating the work area and increased wear and tear on components.

The most common culprits are loose quick couplings, worn seals and broken hoses. Over time, the tightness of the system decreases, resulting in micro leaks - often invisible to the naked eye. That's why it's important to carry out an occasional check with a pressure tester or with specialised leak detection fluids.

If you see stains under the machine or the oil level drops faster than usual, don't underestimate it. Replacing the line is an expense of several tens of zlotys. But an undetected leak can cost several times more if it leads to pump or valve failure.

.png)

Escaping nitrogen and valve failures? This is how you recognise gas problems

Incorrect nitrogen pressure in the tank can result not only in a drop in hitting power, but also in irregular operation and unnatural sounds during operation. The most common problems are either due to a leaking charging valve or an incorrect filling procedure.

Many users do not realise that the nitrogen in the hammer needs to be checked regularly. Lack of the right amount of gas increases vibration and reduces the effectiveness of the work. Added to this is the natural loss of gas over time - especially if the hammer has been unused for a long time or stored in inappropriate conditions.

Remember that all gas work should be carried out according to procedure and preferably with original components. Incorrectly tightened bolts or a dirty charging valve can effectively disable the entire unit. And this is definitely not a cost you want to experience during the job.

When the hammer wears out - how do you recognise worn components and not miss the moment to replace them?

Everything wears out - that much is clear. But when it comes to hammers for excavators with demolition breakers, it's useful to know when wear becomes a threat to the rest of the system. The spearhead, seals, mounting wedge and piston are all parts you need to check periodically.

The spearhead should be replaced at the first crack or cavity, before it leads to uneven force distribution. The retaining wedges should be rotated every 100-150 hours and replaced no later than every 500 hours of operation. As for seals, it is a good idea to set up a maintenance schedule and stick to it as rigorously as possible.

If you're using demolition breakers for mini excavators or hydraulic breakers for mini excavators, bear in mind that often their use is intensive but short-lived. And this is why wear and tear can escape routine maintenance. In such cases, it is best to stick to the manufacturer's maintenance plan and keep a simple record of man-hours.

Read also:

- How to choose a hydraulic breaker for mini excavator?

- The wrong hammer is a big problem. How do you choose the right model for your excavator?

- How does a hydraulic breaker work?

- Hydraulic breakers for excavators with demolition breaker - what to look for when choosing one?

- Excavator demolition breaker operation - how to extend its life?

- When to buy a demolition hammer and when to rent one?

- New tempts with warranty, used with price - how to make a good decision when buying a hydraulic breaker?

- Hydraulic versus pneumatic breakers hammers for excavators - differences, disadvantages, uses

- Impact or hydraulic hammer breaker - which works better for your excavator?

- Don't choose blindly - find out the real differences between hammer and vibratory hammer

- Hydraulic hammer lubrication - which hammer lubricant to choose?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous