Hydraulic earth augers are one of the most versatile attachments for excavators, backhoe loaders and mini excavators. They enable holes to be drilled quickly and accurately in a variety of soil types - from soft earth to hard rock. In this article, you will learn how they work, where they are used and why they have become an indispensable part of modern construction and agricultural machinery.

What are hydraulic earth augers ?

Hydraulic drill rigs are modern work attachments for drilling holes in the ground, mounted on construction equipment equipped with a hydraulic system. The equipment consists of a planetary gear, driven by the flow of hydraulic oil, and an auger bit, the diameter and length of which are selected according to the type of soil and the depth of the borehole. Thanks to their design, hydraulic earth augers make it possible to drill holes for foundations, poles, fences or installations quickly,precisely and energy-efficiently, replacing traditional diesel drill rigs and reducing the need to use heavy equipment.

Hydraulic earth augers for excavators

Hydraulic earth augers for mini excavators and excavators are a solution designed for large construction projects and work in difficult terrain. Mounted on the arm of the excavator, they allow drilling at considerable depths and in demanding soils - from clay to gravel and rock. Thanks to their powerful torque and large working range, these drill rigs are ideal for road construction, civil engineering or foundations for industrial structures. They have the advantage of high stability, precision and the ability to change augers and extensions, making them an extremely flexible tool for the operator.

Hydraulic earth augers for excavators

Hydraulic earth augers for backhoe loaders, on the other hand, represent a compromise between power and mobility. A backhoe loader equipped with a drill rig can perform light fencing, assembly and installation work, as well as more demanding tasks in construction or agriculture. This type of attachment is ideal for construction companies with projects ranging from drilling holes for fences and lighting poles to geotechnical boreholes. Combined with the high manoeuvrability and ease of transport of a backhoe loader, the hydraulic earth auger becomes a versatile and cost-effective solution for many industries.

The typical drilling diameter range for backhoe loader drill rigs is 100-600 mm, with torques as high as 8,000-10,000 Nm, allowing them to work in demanding ground conditions - clay, gravel and even hard soil or conglomerates.

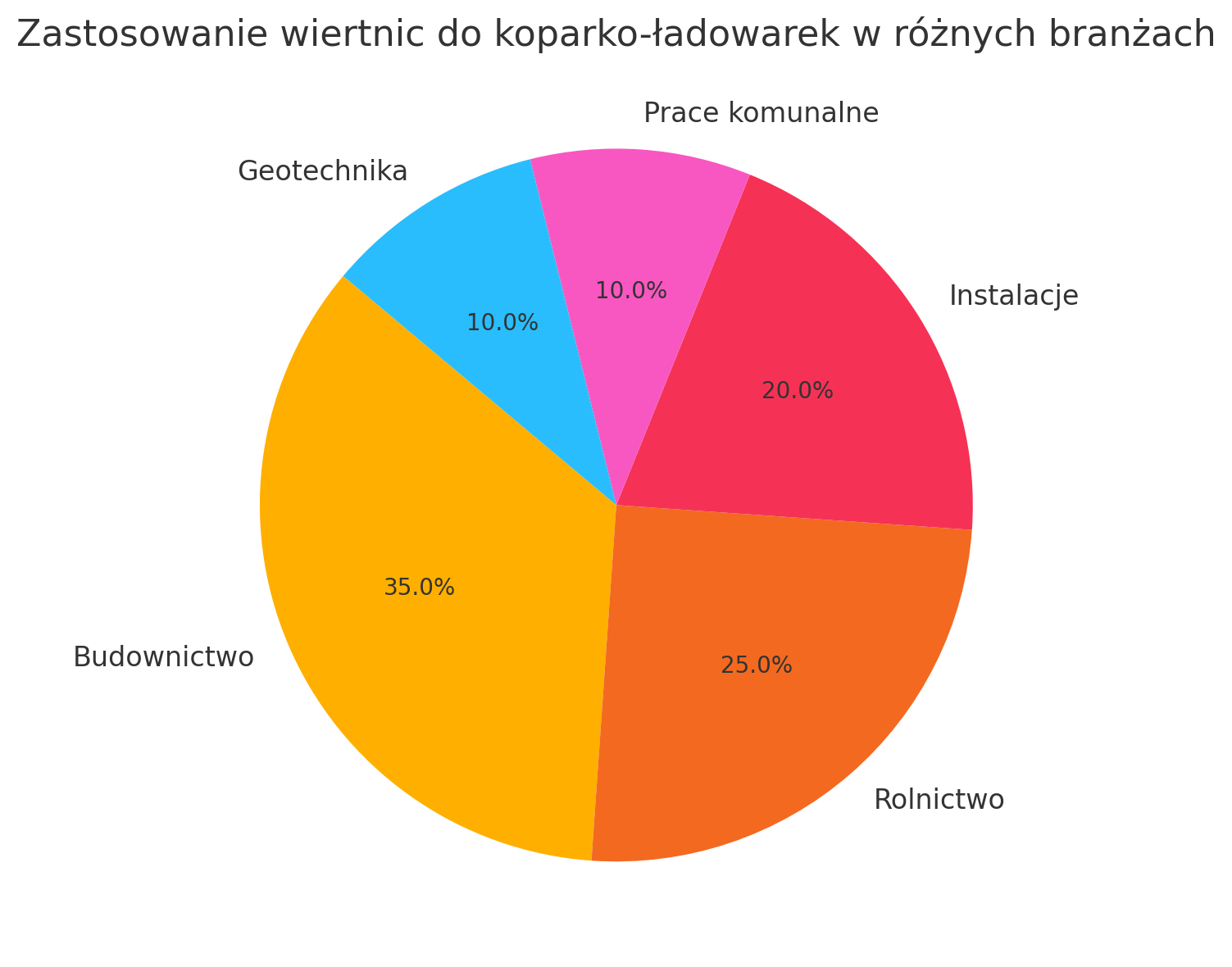

Where are hydraulic earth augers used? Find out about the industries in which they are used

Hydraulic drill rigs are a piece of equipment that is used in a wide range of industries - from construction to agriculture to commercial services. Their versatility makes them suitable wherever fast, precise and repeatable drilling is needed. Thanks to their hydraulic drive and interchangeable augers, they allow efficient work in different types of soil, making them an indispensable tool for everyday field tasks.

Civil and engineering construction

Making holes for point foundations, piles, fences or drainage systems. Backhoe loaders with drill rigs are indispensable on construction sites, where it is often necessary to drill several or dozens of boreholes in a relatively small space.

Infrastructure and energy installations

When installing cable lines, water pipes, lighting poles or road signs, holes with precise dimensions are essential. With interchangeable augers and extensions, drilling up to several metres deep is possible.

Agricultural and forestry work

On agricultural and fruit farms, drilling rigs are used for such purposes as:

- planting trees and fruit bushes,

- installing posts for electric and pasture fences,

- drilling boreholes for greenhouse and foil tunnel constructions.

Geotechnical and test drilling

Drilling rigs for backhoe loaders are often used to prepare test points for geotechnical investigations - prior to the construction of roads, halls, petrol stations or houses. In combination with special augers, test boreholes can be drilled quickly and cost-effectively.

Commercial services

Companies that hire construction equipment or provide earth-moving services often offer a backhoe loader with a drill rig as a complete solution for drilling holes for fence foundations, advertising poles or garden systems.

How do I choose the right hydraulic earth auger for backhoe loader?

Selecting the right hydraulic earth auger for backhoe loader requires taking into account several key technical parameters and the type of work to be carried out. First and foremost, it is importantto match the rig to the power of the machine, i.e. the hydraulic oil flow and operating pressure - for example, models in the CTHB6000-8000 series need a pressure of 80 to 240 bar and a flow of 60-90 l/min. The type of task being performed is also important - different drill rigs will work well for light construction and others for drilling in hard, clay or rocky ground.

Another factor is the diameter of the holes, which is 100-400 mm as standard, although models are available that can drill up to 600 mm and deeper. The depth of drilling is also worth considering, as the deeper the hole, the more powerful the auger should be and the greater the torque of the machine. The type of attachment, which determines the compatibility of the attachment with the machine, is also important - the most common standards are 65, 75 or 110 mm hexagon. All of these elements affect the efficiency of the work, the durability of the attachment and the safety of the drill rig's use in various field conditions.

Examples of the use of a hydraulic earth auger - discover real industrial fencing projects

A contractor company specialising in the installation of industrial fences uses a backhoe loader with a CTHB7000 drill rig installed. In a single working day, it is capable of drilling up to 150 holes with a diameter of 250 mm and a depth of 80 cm in hard clay soil. Thanks to the high torque and the use of fork-tipped augers, the operator avoids downtime and reduces fuel consumption.

The result? A 40% reduction in completion time and operating costs of more than 25% compared to the manual method or hiring a diesel drill rig.

Another example? An industrial customer needed to quickly complete the installation of 300 metres of mesh fencing with metal posts. By using a TEHB3500 drill rig mounted on a backhoe loader, it was possible to complete all the boreholes in just one working day. With an auger diameter of 250 mm and a depth of up to 1.2 m, it was possible to quickly install the posts in a variety of soils from clay to gravel. Work was also carried out in difficult weather conditions - thanks to the hydraulic drive, there was no downtime. The use of this technology contributed to a significant reduction in installation costs and the project schedule.

Drilling rigs for backhoe loaders and mini-excavators - an overview of applications and possibilities

As we have previously described, hydraulic earth augers are extremely versatile attachments that are used in a wide range of industries - from construction to agriculture to infrastructure installations. Now we present more specific application examples that demonstrate the wide range of possibilities this type of equipment offers.

Drilling rigs mounted on backhoe loaders prove themselves in a wide range of tasks such as:

- drilling holes for fences, gates, lighting poles,

- creating point foundations in single-family and light industrial construction,

- installation work - e.g. drilling for water pipes, sewage pipes, optical fibre cables,

- tree and shrub planting (in agriculture and landscaping),

- construction of irrigation systems and pole-fenced pastures,

exploratory drilling in geotechnics and soil testing,

Mini-excavator drilling rigs are used for:

- drilling holes for pergola posts, fixing gazebos, terraces, sheds or lighting points in the garden,

- drilling holes for panel, concrete and metal fence posts, especially on small plots,

- preparing holes for signal masts, power cabinets, surveillance cameras or movement detectors,

- creation of boreholes for waste disposal sheds, external stairs, structural supports or rainwater drainage systems,

- drilling boreholes for drains, drip irrigation systems and drainage of excess water from fields and gardens,

- preparing holes for ground anchors, advertising poles or shallow geothermal probes,

These are just a few examples of mini-excavator drill rig applications that demonstrate their versatility in various fields. In practice, the possibilities of using this attachment are much wider - they are only limited by the nature of the work being carried out and the ingenuity of the operator.

Hydraulic earth auger - an indispensable tool in your fleet!

If you want maximum functionality and a fast return on investment, the hydraulic earth auger is one of the most practical extensions of your excavator's capabilities. Its versatility, wide range of applications and customisable parameters make it an indispensable tool in everyday construction, agricultural and installation work.

Investing in a hydraulic earth auger translates into greater operational efficiency and independence - allowing you to carry out jobs that previously required hiring external equipment or a team of several people. Thanks to the simple installation and operation, and the low number of breakdowns and faults of hydraulic earth augers, the operator can quickly move from digging to drilling, significantly reducing turnaround time and increasing the profitability of any project.

Looking for the right attachments for excavators? Get in touch with a Techna consultant - we'll select a drill rig perfectly suited to your machine and type of job.

FAQ

Which machines can be fitted with a hydraulic earth auger?

Hydraulic earth augers can be fitted to excavators, backhoe loaders, mini excavators and also telescopic handlers. It is only important that the machine has the correct flow and oil pressure in the hydraulic system.

Is a hydraulic earth auger suitable for hard ground?

Yes, modern models with high torque and augers with fork tines can easily handle clay, gravel and even conglomerates and hard soil.

How do I choose an auger for the type of soil?

For soft soils, spiral augers are used, while for hard or rocky soils, augers with fork teeth are used. The choice depends on the planned depth and diameter of the hole.

Is it complicated to mount a drill rig on a backhoe loader?

No, the drill rigs are designed for quick installation - simply connect the hydraulic lines and fit the attachment to the arm of the machine.

What is the service life of a hydraulic earth auger?

With correct operation and regular servicing, a drill rig can operate faultlessly for many years, even in intensive construction conditions.

Do hydraulic earth augers require frequent maintenance?

No, the drill rigs are simple devices with few moving parts - regular cleaning and checking the hydraulic oil level is sufficient.

Can hydraulic earth augers be used in winter?

Yes, but it is advisable to use hydraulic oils suitable for low temperatures and to prepare the machine appropriately for frosty conditions.

What are the operating costs of a hydraulic earth auger?

These are considerably lower than for diesel drill rigs - the hydraulic drive reduces fuel consumption and minimises engine servicing.

Can one drill rig work with different machines?

Yes, provided the correct attachment is used and the hydraulic parameters are adapted. Many models have universal adaptors for added flexibility.

What are the biggest advantages of a hydraulic earth auger?

Among the most important are high productivity, low operating costs, precise drilling and a wide range of applications in construction, agriculture and geotechnics.

Read also:

- How to choose the right hydraulic earth auger for mini excavator?

- Drilling rigs for crawler excavators - what should you know before buying?

- Hydraulic earth auger for backhoe loader - what to look out for to get the right equipment?

- Proper operation of hydraulic earth augers

- Types of excavator drilling rigs - which ones to choose for specific tasks and materials?

- When to buy a new or used hydraulic earth auger - how to make the right decision?

- Hydraulic earth auger - when is it worth buying and when is it better to rent?

- Hydraulic earth augers for excavators - what to choose hydraulic, mechanical or pneumatic drive?

- The most common breakdowns and faults in hydraulic earth augers - how to solve them?

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous