A poorly selected screening bucket means not only lower productivity, but also a risk of damage to the excavator and costly downtime. The choice of a particular model should always be based on the technical parameters of the machine, the type of material to be screened and the working conditions. Without an understanding of these relationships, it is easy to buy an attachment that fits in theory - but fails completely in practice. See what to look out for to avoid the most common mistakes and to match the bucket to your real needs.

Not every screening bucket fits every excavator - how do you choose a model to suit the parameters of your machine?

There is no one-size-fits-all screening bucket that will work for all types of machines. What works well on a medium-sized backhoe loader may be completely ineffective on a heavier crawler excavator. Properly matching the screening bucket to the machine parameters is the first and most important step - not only for productivity, but also for operator and equipment safety.

The weight of the machine, its working force and the geometry of the arm all matter.

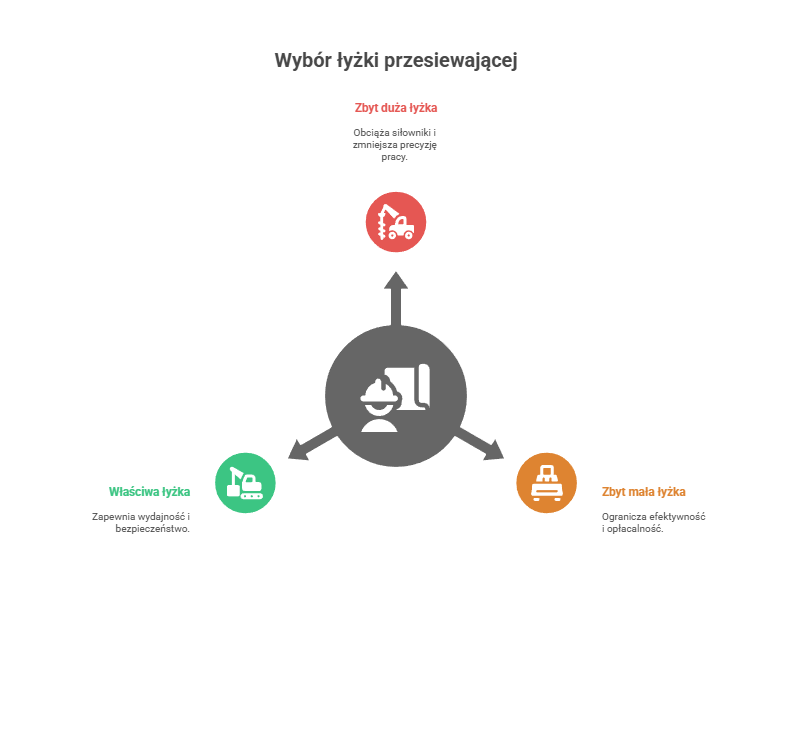

- A bucket that is too large or too heavy will put a strain on the cylinders, affect wear on components and significantly reduce precision.

- On the other hand, one that is too small will reduce efficiency and make each working hour less profitable.

A good starting point is always to consult the supplier - not only for installation, but also to verify compatibility with hydraulics, lifting capacity and arm design. You will thus avoid a situation in which the bucket you have purchased turns out to be an investment for the drawer. If you have questions, get in touch with one of our advisors at technapoland.com.

Hydraulic parameters that many forget - and which can ruin your attachment!

Excavator hydraulics are a system precisely calibrated for specific pressures and flows. Ignoring these values when selecting a screening bucket can end in serious damage. An overloaded hydraulic system doesn't just mean costly downtime - it also means risking permanent damage to the pump or valves.

Before you choose a particular model, check the maximum oil flow (l/min) and the required operating pressure of the bucket. These figures must coincide with what your excavator offers. If the attachment has higher requirements than the system, it will not work properly or will work too slowly. If the reverse is true, the system may overheat or wear out faster than it should.

Not every excavator has the same hydraulic system. Older machines often require separate control valves or system adjustments. For this reason, it is advisable to consult a technical advisor before purchasing, or go for proven parts for excavators dedicated to specific models.

Choosing a screening bucket for excavators. Bucket capacity and dimensions - how not to overload the machine and lose productivity?

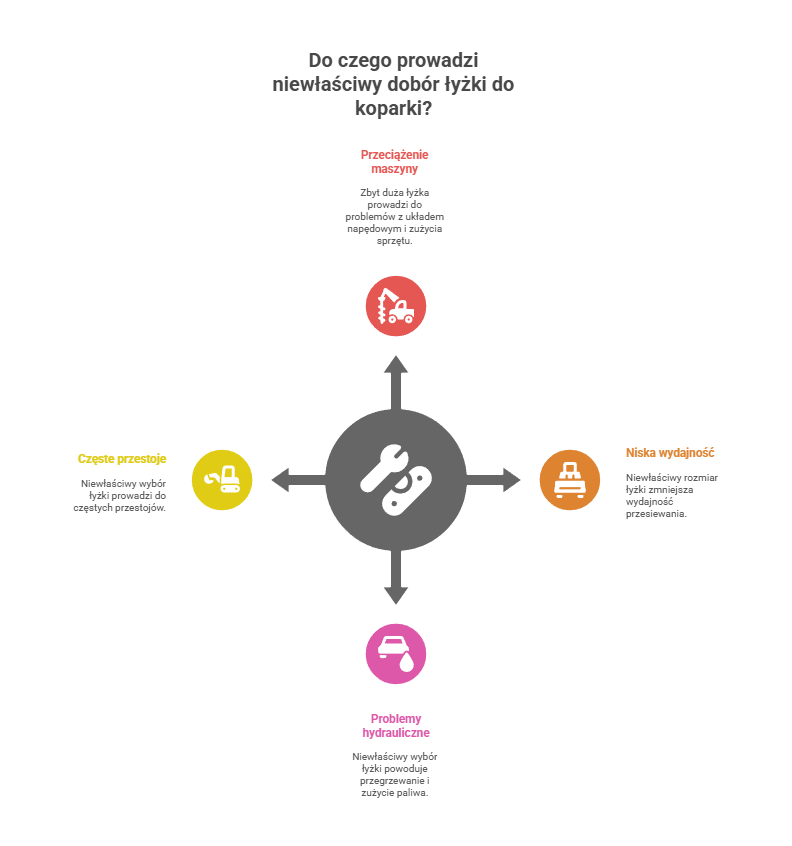

It is impossible to talk about efficient work without choosing the right working capacity. A screening bucket that is too large can cause the drive train to "signal" that something is wrong after just a few minutes of operation. The excavator will lose precision and the entire attachment will be exposed to excessive wear.

The screening capacity depends directly on the bucket to excavator weight ratio. For machines in the 12-20 tonne range, buckets of 0.6-0.8 m³ are the most common choice, while lighter machines require more compact solutions. What's more - the length of the arm also affects force distribution and stability. All of this should be taken into account before equipment goes on site.

Ignoring these parameters results in, among other things, overheating of the hydraulic system, excessive fuel consumption and frequent stoppages. If you are looking for a robust and tailored solution, check out the screening buckets for excavators available - you will find specific options for different weight classes of machines.

Hard rubble or peat? The choice of screening system is crucial

Not every material requires the same screening technology. Peat, garden soil, dry sand - these are light and loose fractions that do not offer much resistance. However, when rubble, concrete or clay with stones mixed in come into play, a classic bucket may not be enough.

The screening system must be adapted to the type of material. When choosing attachments for working with building rubble, it is worth opting for buckets with a reinforced frame and adjustable mesh size. Models with a hydraulic rotary drive also work well, as this speeds up the separation process and allows better use of the machine's power.

When sieving peat or organic materials, systems with a softer drive - less aggressive but more precise - will work better. A poorly chosen mechanism is not only a waste of time, but also risks damaging the bucket itself or overloading the system.

An assembly that makes a difference - how do you choose a screening bucket for your system?

Just because a bucket fits the dimensions and weight of your excavator does not yet mean that it will work correctly. The attachment system is of paramount importance for efficiency, comfort and safety. An ill-fitting quick coupler can cause backlash, vibration and, in extreme cases, complete disconnection during operation.

Check that the bucket is compatible with the quick coupler used on your machine. Some systems require additional adaptors, others are universal. It is also crucial whether the installation allows the hydraulics to flow freely and does not require reworking of the system.

Operating costs without secrets - what really makes the investment worthwhile?

The purchase price of a bucket is one thing - but it is the running costs that determine whether the investment pays off after a few months or only after years. What is worth paying attention to? First and foremost, the quality of the working components, their availability and how easy they are to replace.

If bearings, screens or hydraulics are difficult or expensive to access, any downtime will hit your profitability. It is therefore advisable to choose products for which wear parts are standard or readily available on the market. The same applies to lubrication, filtration systems and the mechanical resistance of materials.

Remember - a bucket that costs less when you buy it may turn out to be more expensive to operate if it requires frequent repairs or unforeseen downtime. If you want to avoid such situations, choose wisely - preferably from among proven screening buckets for excavators that have a service background and a good reputation among users.

How can you tell if a manufacturer provides real support? Service, parts and availability

In theory, every manufacturer provides support. In practice - only contact with the service department will show what this really looks like. Unfortunately, this is often only after something has already happened. That is why it is worth thinking about the quality of service even before purchasing.

It is not only the availability of spare parts that counts, but also the service response time and the competence of the advisors. Do they have the technical documentation? Can they recommend a suitable replacement? Do they have a warehouse on site or do they pull everything from abroad? These are questions you should ask before you sign an order.

A good manufacturer or supplier not only sells, but also helps when equipment stops working. Therefore, when choosing a screening bucket, pay attention not only to the product itself, but also to the people behind it.

Want to know which screening bucket will work best for your machine? Check out our full range of screening buckets for excavators and get in touch with our technical advisor - we'll help you choose attachments that will really boost your productivity.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous