The screening bucket is one of the most innovative and cost-effective pieces of equipment used in modern construction, recycling and waste management. Its main function is to select and separate fractions of material without the need to transport it to an external sorting plant. This significantly speeds up and streamlines work on site, while reducing the costs associated with transport, disposal and the purchase of new aggregate.

Screening bucket - what is this equipment and when is it worth using?

The screening bucket is an extremely practical hydraulic attachment for excavators, loaders and mini excavators. Thanks to a special sifting mechanism, it makes it possible to separate construction material of various sizes - from small fractions of soil to larger pieces of rubble or stones.

This equipment significantly speeds up sorting work and eliminates the need for manual separation of materials. Importantly, screening buckets for excavators are available in many variants, so they are successfully used for a variety of tasks: from screening soil, sand and gravel, to sorting demolition waste, to clearing beaches and separating river stones.

In short: one machine - many uses, less downtime and greater efficiency.

How does the screening bucket work? Simple, but effective!

The screening bucket's operating mechanism is based on a rotating basket, inside which screens of a specific mesh size are placed. Once the material is loaded, a hydraulic system sets the basket in motion - and this is when the "magic" begins.

Finer fractions, such as earth, sand or rubble, fly through the mesh of the screen and are deposited directly on the construction site. Larger pieces - such as concrete, bricks or stones - on the other hand, remain in the bin from where they can be transported or disposed of.

This solution not only eliminates the need for stationary screeners, but also allows the operator to be mobile without changing location. This makes earthmoving and demolition work simpler, faster and cheaper.

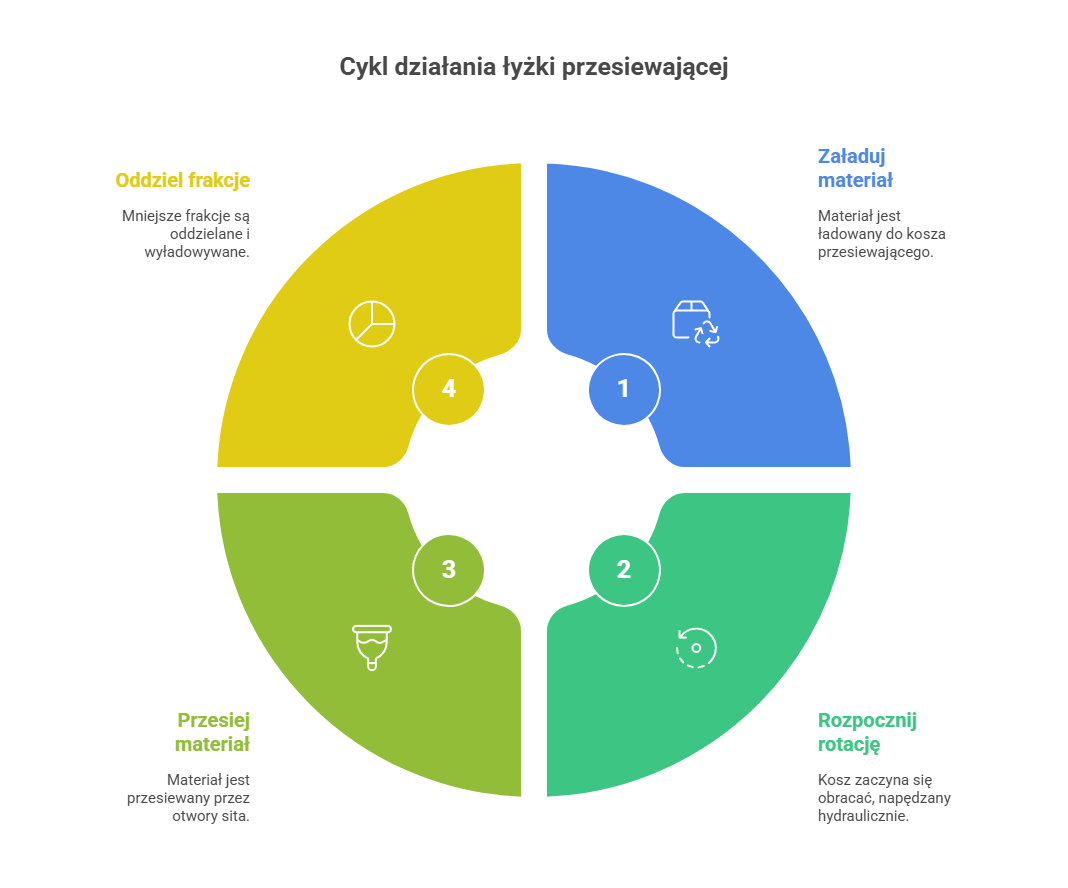

How does the screening bucket work? Step by step

Operating a screening bucket is not complicated, but it is useful to know what happens inside when the material goes into the bin. Here are the three four steps in the operation of this attachment - from loading to separating fractions.

1 Loading the material

The process starts with filling the screening bucket with material - this can be soil, rubble, river stones, compost or sand. The material goes into a specially designed cylindrical screening basket inside the bucket.

IMPORTANT: Do not load materials larger than ¼ the diameter of the basket! Example: for a basket with a diameter of 800 mm, the maximum diameter of the material should not exceed 200 mm.

2 Start of rotation - hydraulic drive in action

After loading, the operator activates the hydraulic mechanism. Inside the bucket, the screening bucket starts to rotate - it can rotate clockwise or anti-clockwise (thanks to the rotation mechanism on both sides).

The speed of rotation depends on the flow of hydraulic oil - supply is via the IN connector.

3. sifting the material through the screen openings

The rotating basket sets the material in motion, which begins to be crushed and separated. Anything smaller in size than the sieve openings flies through and is discharged to the ground as a finished, sieved fraction.

The interchangeable screens allow you to adjust the size of the openings as required - e.g. 10 mm, 20 mm, 30 mm - depending on what you want to obtain: aggregate, soil for reclamation or ballast for paving stones.

4 Retaining large pieces, sifting out small ones

Larger pieces (e.g. bricks, stones, construction waste) remain in the bucket - they do not pass through the screen. The operator can easily dispose of them once the sieving is complete, and the sieved material can be immediately reused.

Operator errors - what to avoid when operating a screening bucket?

Although the operation of a screening bucket seems simple, improper use can lead to serious malfunctions, lost time and even accidents.

Example 1 - loading stones that are too large

An operator loads rubble without prior selection. The material contains concrete fragments with a diameter of 400 mm, while the screening basket is only 800 mm in diameter (the permitted size is 200 mm). The result?

- Blocking of the rotary mechanism.

- Risk of cracking or deforming the basket.

- Site downtime and costly repair.

Example 2 - changing direction without stopping

An operator switches the direction of rotation without stopping the rotation. The result?

- Damage to the planetary gearbox

- Leakage of hydraulic lines

- Loss of warranty (if prohibited by the manufacturer)

Example 3 - using the bucket as a digging or impact tool

The screening bucket is not designed to impact or support the machine. Using it as an excavator can:

- damage the attachment system,

- bend the frame or guards,

- cause the rotor drive to fail.

Screening bucket operation vs. bi-directional rotation - greater control and productivity

In standard screening buckets, the drum only rotates in one direction. But if you want smoothness, precision and flexibility, opt for a model with bi-directional rotation - a detail that makes a huge difference in practice.

Being able to work both clockwise and anti-clockwise gives the operator a whole new level of control. In practice, this means that:

- it is easier to release blocked material without having to stop working,

- you can adjust the rotation to suit the terrain, angle of attack and type of fraction,

- you gain greater manoeuvring precision, which speeds up screening in more difficult conditions,

- you reduce the risk of downtime and lost time - and that translates directly into costs.

The operator doesn't have to fiddle around - all it takes is one movement of a lever and the hopper turns the other way. This is what makes Techna equipment not only work, but work efficiently, safely and without unnecessary surprises.

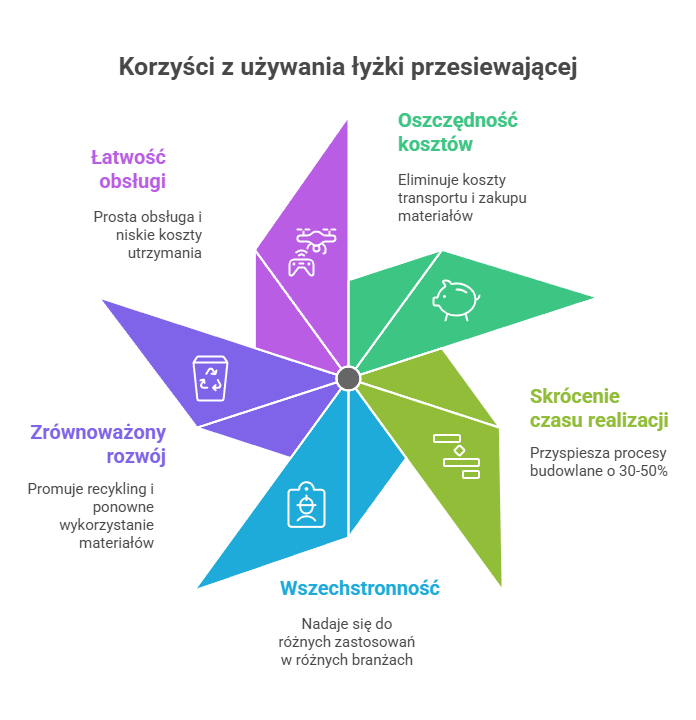

What do you gain by using a screening bucket? Discover the 5 key benefits!

- Cost savings - screening material directly on site eliminates the need to hire external screeners, reduces transport costs and the purchase of new aggregate. Less hauling, less buying, more profit.

- Reduced lead time - the whole process takes place on site, so you don't waste time loading, transporting or waiting for recycling. Turnaround time can be reduced by up to 30-50% - and that already makes a difference to your schedule.

- Versatility of use - one machine, many possibilities. Screening buckets work well in earthworks, demolition, reclamation and even in sewer cleaning, scrap sorting or compost work. They suit a variety of industries and conditions.

- Ecology and sustainability - instead of taking everything to landfill - sift, recycle and reuse. Rubble or earth from the construction site can be used as fill material, stabiliser or sub-base, in line with the principles of the circular economy.

- Easy to operate and low operating costs - buckets are easy to assemble and use, requiring no specialised training. Thanks to their simple design and durable materials , they are cheap to maintain and can withstand intensive use.

Bottom line - simple principle, powerful results

Thanks to its clever design and rotary screening system, the screening bucket allows valuable material to be separated from waste quickly, precisely and cost-effectively. However, like any machine - it requires correct operation, knowledge of limitations and adherence to instructions.

The screening bucket is an attachment for excavators that significantly improves the efficiency of construction and earthworks. It reduces costs, increases mobility, reduces working time and promotes material recycling. If you want to optimise your work on site - choosing a screening bucket is an investment that will quickly pay off.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous