Hydraulic attachments for excavators are the standard in construction, demolition and earthmoving work today. Equipment such as demolition jaws, crushing jaws or hydraulic pile drivers provide tremendous productivity, but only if they are properly operated and serviced.

Want to ensure your grapple doesn't lose power with each passing day? Here's a list of key maintenance rules to help keep it in optimum shape - and take care of your other hydraulic pile drivers, such as the PD530S and PD530SB.

Why does maintenance matter?

Hydraulics is a precision system. One minor oversight - a leak, dirty oil, a bent bushing - and the machine starts to run slower, weaker, less precise. And that translates into productivity, safety and turnaround time.

For demolition grabs, the symptoms of problems can be subtle:

- weaker grip,

- uneven rotator action,

- a delay in jaw response.

It's not the operator's fault - it's a signal that service or cleaning is needed.

The 5 most common mistakes that reduce gripper power

1. lack of regular lubrication of pins and bushings

In intensive use, the gripper jaws move hundreds of times per hour. Without lubrication - they wear out rapidly.

Dirty hydraulic couplings and joints

Dust, mud and metal filings can block the flow of oil or damage seals.

3. leaks in the system

Drop in pressure = drop in gripping power. Small leaks are worth locating straight away, before the performance of the whole system drops.

Inadequate oil pressure and flow

Each gripper has specific operating parameters. Too high a pressure can damage the actuator. Too low - will make the unit weak and retarded.

No inspection of the 360° rotator.

If the gripper 'jams' or works in leaps and bounds, a blocked valve or worn rotating bearing may be the culprit.

What to do to keep your gripper running like new?

Daily check before operation:

- visually check all hydraulic connections,

- wipe the quick couplings before connecting them,

- check the level and condition of the hydraulic oil in the machine.

Lubrication:

- regularly lubricate all moving points (pins, guides, rollers),

- use dedicated grease for construction conditions - resistant to moisture and high pressure.

Every 50-100 operating hours:

- check the tension and condition of the hydraulic lines,

- test rotator response - it should run smoothly and without delay,

- check the condition of the jaws - if the grip is uneven, there may be slack or contamination.

Every few months:

- flush the hydraulic system (if you work in a dusty environment),

- change the filters and check the cylinder for play.

What about other hydraulic equipment?

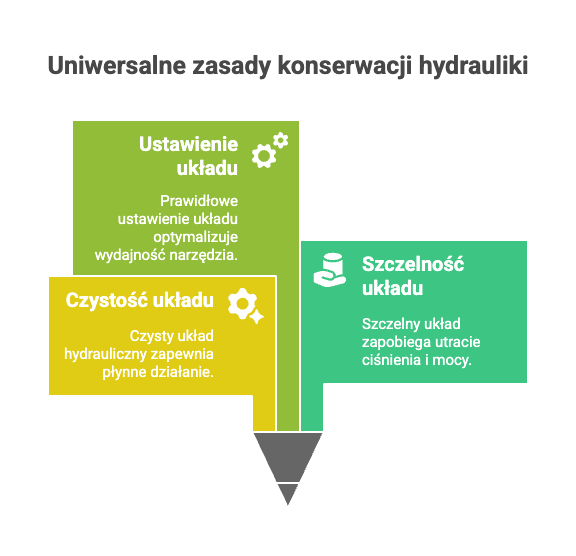

The principles of hydraulic care are universal - so it's worth applying them to other tools too, such as hydraulic pile drivers PD530S and PD530SB, which also use pressure and oil flow to operate.

Example:

The PD530S pile driver generates as many as 1,100 blows per minute - at an energy of 720 J. To achieve full power, the system must be clean, tight and well adjusted. A dirty valve or too low a flow rate will limit the hammering power and can lead to overheating of the equipment.

Good maintenance practices (not just for pickers):

- Don't leave attachments out in the rain or mud - if not working, store them on a pallet or under a canopy.

- Use only original parts and lubricants - especially in rotary and impact attachments.

- React to a drop in performance straight away - the sooner you detect a problem, the less risk of a costly repair.

- Keep a simple service record - record dates for maintenance, lubrication and any replacements. It pays off.

Bottom line: power = care + service

Even the best gripper, pile drivers or jaws will lose strength over time - if you don't take care of their hydraulics. Fortunately, maintenance doesn't have to be difficult or expensive. All it takes is a few simple habits to keep your attachments running at full power, without downtime or breakdowns.

Have questions about servicing your equipment?

Get in touch with us - we can advise you, help you choose parts and give you tips on what to do to keep your equipment running like new.

Read also:

Shears, demolition jaws for excavators

Shears, demolition jaws for excavators

Hydraulic drill rigs

Hydraulic drill rigs

Hydraulic pile drivers for excavators

Hydraulic pile drivers for excavators

Screening buckets for excavators

Screening buckets for excavators

Hydraulic grapples for excavators

Hydraulic grapples for excavators

Chain trenchers

Chain trenchers

Mixing buckets for excavators

Mixing buckets for excavators

Flail mowers

Flail mowers

Previous

Previous